Reduced-pressure ultrafiltration membrane distillation device and reduced-pressure ultrafiltration membrane distillation method

A distillation device and ultrafiltration membrane technology, applied in the field of membrane separation, can solve the problems of membrane fouling, hydrophobic membrane hydrophilization leakage, membrane distillation flux and low mechanical strength of the membrane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

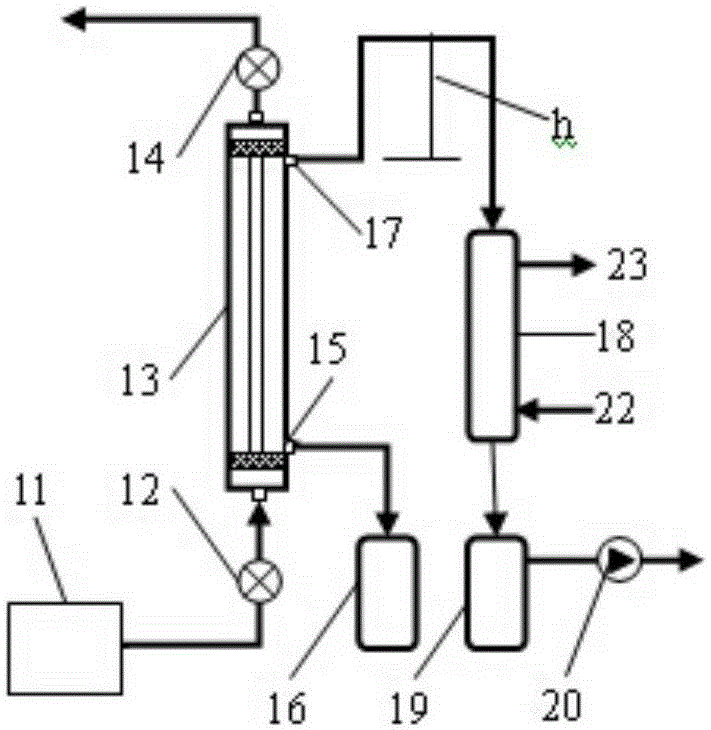

[0040] Embodiment 1, adopt as image 3 The decompression ultrafiltration membrane distillation device uses tap water as the raw material liquid, and enters the tube of the ultrafiltration membrane module from bottom to top. The conductivity of the tap water is 360μS / cm, and the temperature of the tap water is 60°C. (self-made, code name M-1) is used as the ultrafiltration membrane after wetting with ethanol, carries out the decompression ultrafiltration membrane distillation process, sets the height h of the vertical pipe section to be 15cm, and the vacuum negative pressure is 0.089MPa, and the membrane distillation flux that obtains is 15L / ㎡.h, the conductivity of membrane distillation water is 4.2μS / cm.

Embodiment 2

[0043] Example 2, using a hollow fiber ultrafiltration membrane module (self-made, code M-2), and the rest of the conditions are the same as Example 1. The obtained membrane distillation flux is 15L / ㎡.h, and the conductivity of membrane distillation water is 4.1μS / cm.

[0044] The pure water ultrafiltration membrane flux of the M-1 membrane module is 280L / ㎡.h@0.10MPa. The outer area of the hollow fiber membrane of the M-2 membrane module and the M-1 membrane module is the same. The ultrafiltration membrane flux is 1080L / ㎡.h@0.10MPa, much higher than the M-1 membrane module. By comparison of Example 1 and Example 2, the membrane distillation flux has nothing to do with the pore size and ultrafiltration flux of the ultrafiltration membrane used.

Embodiment 3

[0045] Embodiment 3, adopt as Figure 4 The decompression ultrafiltration membrane distillation device uses tap water as the raw material liquid, which enters the tube side of the ultrafiltration membrane module from bottom to top. The conductivity of the tap water is 360μS / cm, the temperature of the tap water is 60°C, and the circulation velocity of the raw material liquid is 0.40m / S . The hydrophobic membrane module (self-made, code M-1) with an area of 0.05㎡ is wetted with ethanol and used as an ultrafiltration membrane to carry out the vacuum ultrafiltration membrane distillation process. The vertical pipe section height h is set to 15cm, and the vacuum negative pressure is 0.089MPa. The obtained membrane distillation flux is 22L / ㎡.h, and the conductivity of membrane distillation water is 4.2μS / cm. Through the circulation of the raw material liquid, it is beneficial to increase the temperature of the evaporated clear liquid, thereby increasing the flux of the membrane d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Separation aperture | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com