Catalyst used for coal hydrogenation catalytic gasification, and preparation method and use thereof

A catalyst and coal hydrogenation technology, applied in the field of catalysis, can solve the problems of low methanation yield and weakened catalyst effect, and achieve the effects of increasing H2 content, promoting methanation reaction, high conversion rate and methane generation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

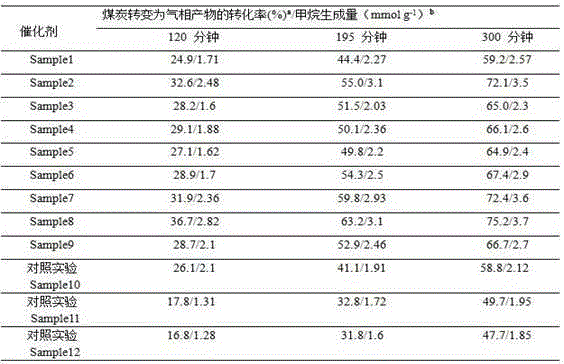

[0018] 0.25 g Ni(NO 3 ) 2 , 0.16 g Mn(Ac) 2 and 3.79 g C 18 h 29 NaO 3 Dissolve S in 40 ml of deionized water, then add 5 g of bituminous coal to the above solution, stir well to make it evenly mixed, add the above solution into a high-pressure reactor, and conduct a hydrothermal treatment at 3.5MP, 180°C for 5 hours, and the high-pressure reaction The materials in the kettle were taken out, washed and dried, pressed into tablets, ground and sieved, marked as Sample 1, and set aside. The change curve of the conversion rate of coal to gaseous products on the catalyst with time and the CH 4 The production quantities are shown in Table 1.

Embodiment 2

[0020] 0.25 g Ni(NO 3 ) 2 , 0.16 g Mn(Ac) 2 and 3.48 g C 18 h 33 o 2 Na was dissolved in 40 ml of deionized water, then 5 g of bituminous coal was added to the above solution, stirred thoroughly to make it evenly mixed, and the above solution was added to a high-pressure reaction kettle, and hydrothermally treated at 3.5MP, 180°C for 5 hours, and the high-pressure reaction The materials in the kettle are taken out, washed, dried, pressed into tablets, ground and sieved, marked as Sample 2, and set aside. The change curve of the conversion rate of coal to gaseous products on the catalyst with time and the CH 4 The production quantities are shown in Table 1.

Embodiment 3

[0022] 0.25g Ni(NO 3 ) 2 , 0.16g Mn(Ac) 2 and 3.28g C 18 h 33 o 2 K was dissolved in 40 ml of deionized water, then 5 g of bituminous coal was added to the above solution, fully stirred to make it evenly mixed, the above solution was added to the autoclave, and hydrothermally treated at 3.5MP, 180°C for 5 hours, the The materials in the kettle are taken out, washed, dried, pressed into tablets, ground and sieved, marked as Sample3, and set aside. The change curve of the conversion rate of coal to gaseous products on the catalyst with time and the CH 4 The production quantities are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com