Composition additive for laser marker

A technology of laser marking and composition, which is applied in the field of laser marking additive composition, can solve the problem of high light wave transmittance, and achieve the effect of fast response and sufficient energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] Preparation of Laser Marking Additive Microparticles:

[0020] P-toluenesulfonic acid (including its homologues) is a strong acid, which can react with oxides (or hydrates of oxides) in aqueous solution, evaporate to dryness, then dry at 110°C-140°C for 30 minutes, cool and grind to D50 is between 10-50um.

[0021] Marking sample preparation and performance measurement:

[0022] Blending, granulation, and tableting by conventional methods are used to prepare polymer test pieces containing the laser marking additive particulate composition.

[0023] Mark with the laser marking machine model KDD-50 produced by Suzhou Kaitai Laser Technology Co., Ltd. Marking process conditions: current: 9-13A; scanning speed: 500-2000mm / min.

[0024] The color difference was measured with a model 7000A colorimeter from X-Rite Company of the United States. According to the CIE Lab color space, from the measured ΔL, Δa and Δb of the label, ΔE was calculated. According to literature rep...

Embodiment 1

[0032] Press Sb 2 o 3 : p-toluenesulfonic acid=1:2 (molar ratio) react at (110°C) to obtain the composition. Polymer PE. Marking scanning speed: 500mm / s. Color of the polymer added to the particulate composition after processing: white.

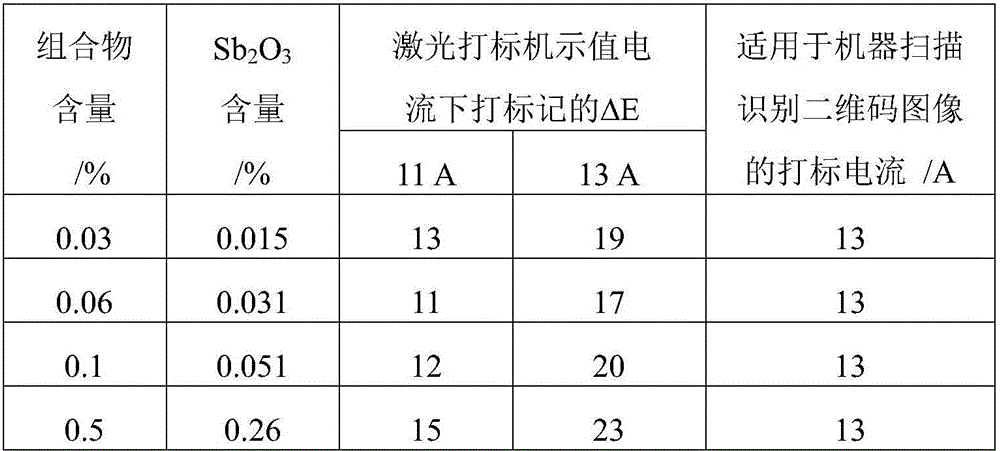

[0033] Test Results

[0034]

Embodiment 2

[0036] Press Sb 2 o 3 : p-toluenesulfonic acid=1:4 (molar ratio) reacted at 125°C to obtain a composition. Polymer PE. Marking scanning speed: 500mm / s. The color of the polymer added to the particulate composition remained white after processing.

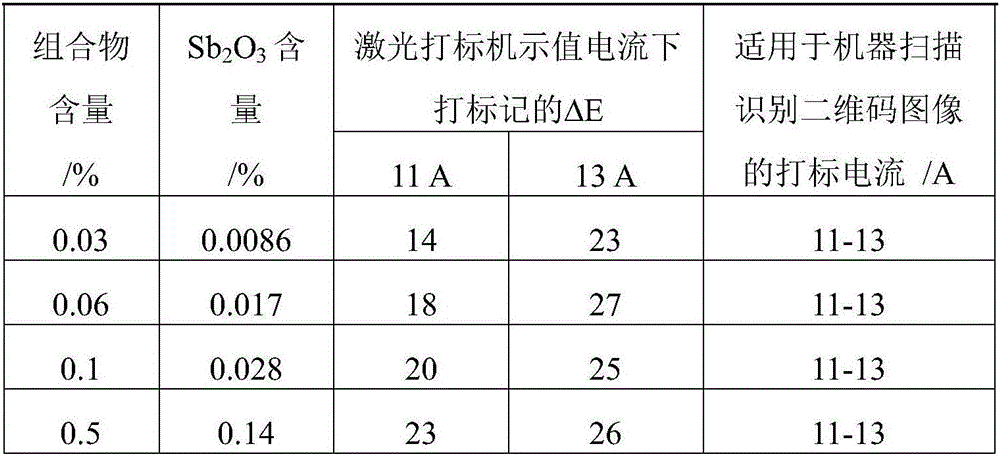

[0037] Test Results

[0038]

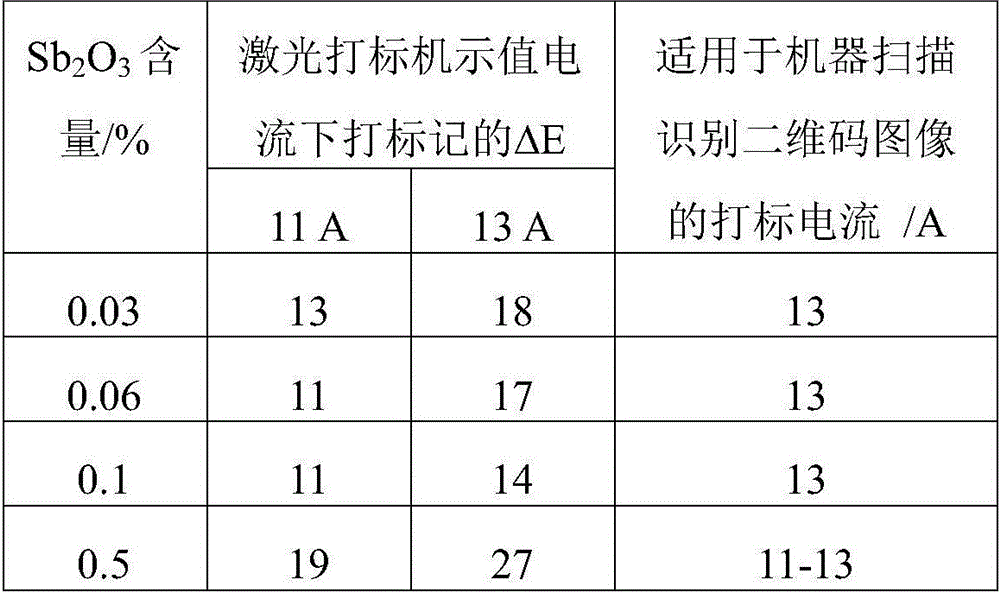

[0039] comparative data

[0040]

[0041] Comparative example 1, embodiment 2 and comparative example data can confirm to modify Sb with p-toluenesulfonic acid 2 o 3 at the same Sb 2 o 3 The ΔE of the label can be greatly improved at a lower content; especially, the effect of a high content of p-toluenesulfonate in the additive is more significant than a low content. Example 3

[0042] Press Bi 2 o 3 : p-toluenesulfonic acid=1:2 (molar ratio) 110°C reaction to obtain the composition. Polymer PE. Marking scanning speed: 500mm / s. Color of the polymer added to the composition after processing: white.

[0043] Test Results

[0044] Composition content / % Bi 2 o 3 content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com