High temperature resistant epoxy pouring sealant, preparation method and application thereof as packaging material in IGBT module

A technology of potting glue and high temperature resistance, which is applied in the direction of epoxy resin glue, adhesive, non-polymer adhesive additives, etc. It can solve the problems of poor high temperature resistance and the rapid development of the industry that limits the use of epoxy potting materials. , to achieve good sealing protection, low curing heat release, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

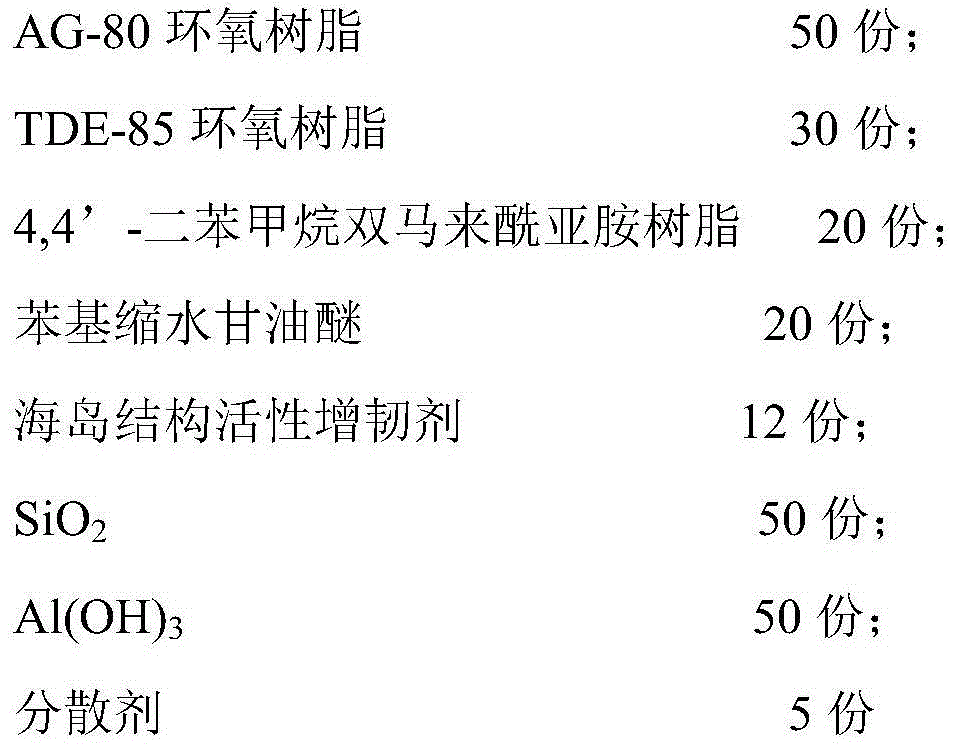

Embodiment 1

[0030] A high temperature resistant epoxy potting glue, the epoxy potting glue contains main agent A and curing agent B:

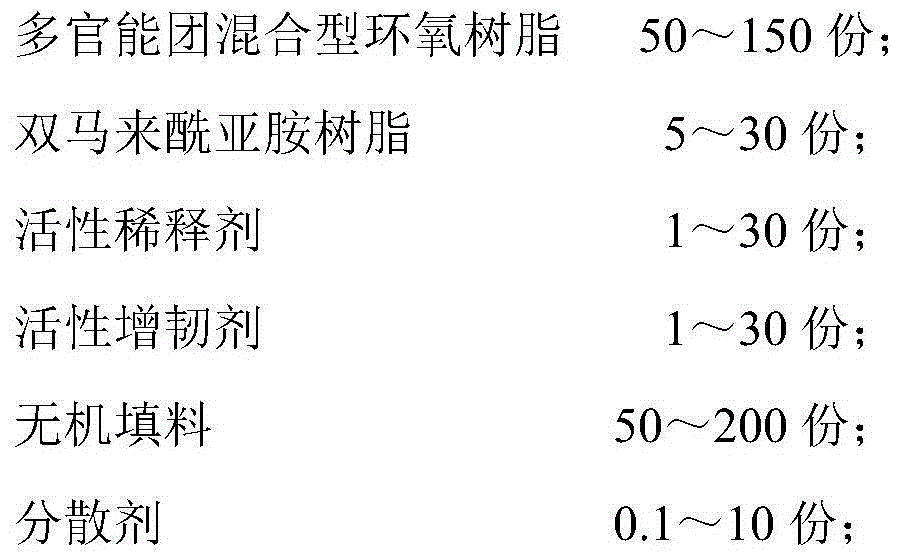

[0031] The main agent A is mainly composed of the following components in parts by mass:

[0032]

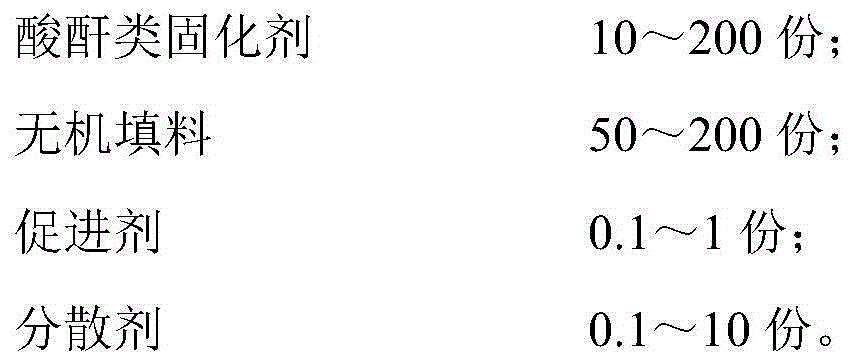

[0033] Curing agent B is mainly composed of the following components in parts by mass:

[0034]

[0035] The preparation method of the above-mentioned high temperature resistant epoxy potting glue of this embodiment includes the preparation of the main agent A and the preparation of the curing agent B;

[0036] The preparation of main agent A includes the following steps: Preheat 50 parts by mass of AG-80 epoxy resin and 30 parts by mass of TDE-85 epoxy resin at 100°C for 30 minutes, and then add 20 parts by mass of 4,4'-bis Benzene bismaleimide resin was stirred at a low speed for 30 minutes, the stirring speed was 1000r / min, the temperature was lowered to below 50°C, and then 20 parts by mass of phenyl glycidyl ether and 12 parts by mass of sea-isla...

Embodiment 2

[0045] A high temperature resistant epoxy potting glue, the epoxy potting glue contains main agent A and curing agent B:

[0046] The main agent A is mainly composed of the following components in parts by mass:

[0047]

[0048] Curing agent B is mainly composed of the following components in parts by mass:

[0049]

[0050] The preparation method of the above-mentioned high temperature resistant epoxy potting glue of this embodiment includes the preparation of the main agent A and the preparation of the curing agent B;

[0051] The preparation of main agent A includes the following steps: Preheat 60 parts by mass of AG-80 epoxy resin and 40 parts by mass of TDE-85 epoxy resin at 90°C for 30 minutes, and then add 20 parts by mass of 4,4'-di Benzene bismaleimide resin was stirred at a low speed for 30 minutes, the stirring speed was 800r / min, the temperature was lowered to below 50°C, and then 20 parts by mass of phenyl glycidyl ether and 12 parts by mass of sea-island ...

Embodiment 3

[0060] A high temperature resistant epoxy potting glue, the epoxy potting glue contains main agent A and curing agent B:

[0061] The main agent A is mainly composed of the following components in parts by mass:

[0062]

[0063] Curing agent B is mainly composed of the following components in parts by mass:

[0064]

[0065] The preparation method of the above-mentioned high temperature resistant epoxy potting glue of this embodiment includes the preparation of the main agent A and the preparation of the curing agent B;

[0066] The preparation of main agent A includes the following steps: preheat 80 parts by mass of F-76 epoxy resin and 40 parts by mass of AG-90 epoxy resin at 100°C for 30 minutes, and then add 30 parts by mass of 4,4'-di Benzene bismaleimide resin was stirred at a low speed for 30 minutes, the stirring speed was 800r / min, the temperature was lowered to below 50°C, and then 30 parts by mass of phenyl glycidyl ether and 18 parts by mass of sea-island s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com