Metal-air battery positive electrode and metal-air battery

A metal-air battery and positive electrode technology, applied in battery electrodes, fuel cell half-cells and primary battery-type half-cells, fuel cell-type half-cells and secondary battery-type half-cells, etc., can solve redox Reduced reaction rate, reduced energy conversion efficiency and power density of metal-air batteries, reduced oxygen and metal ion transport capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

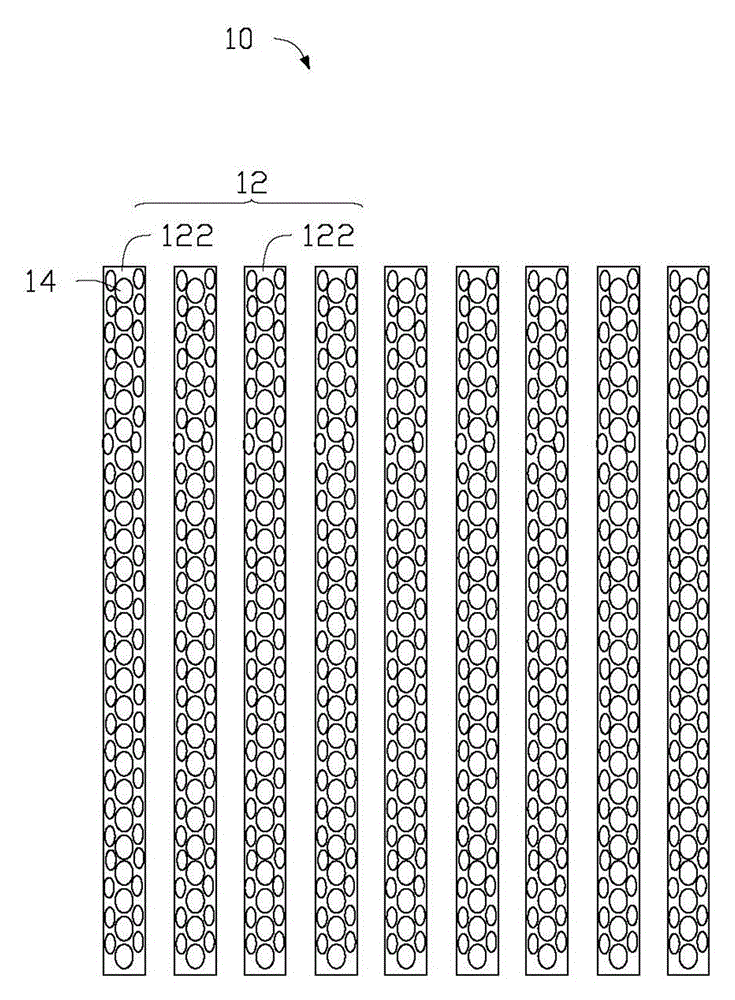

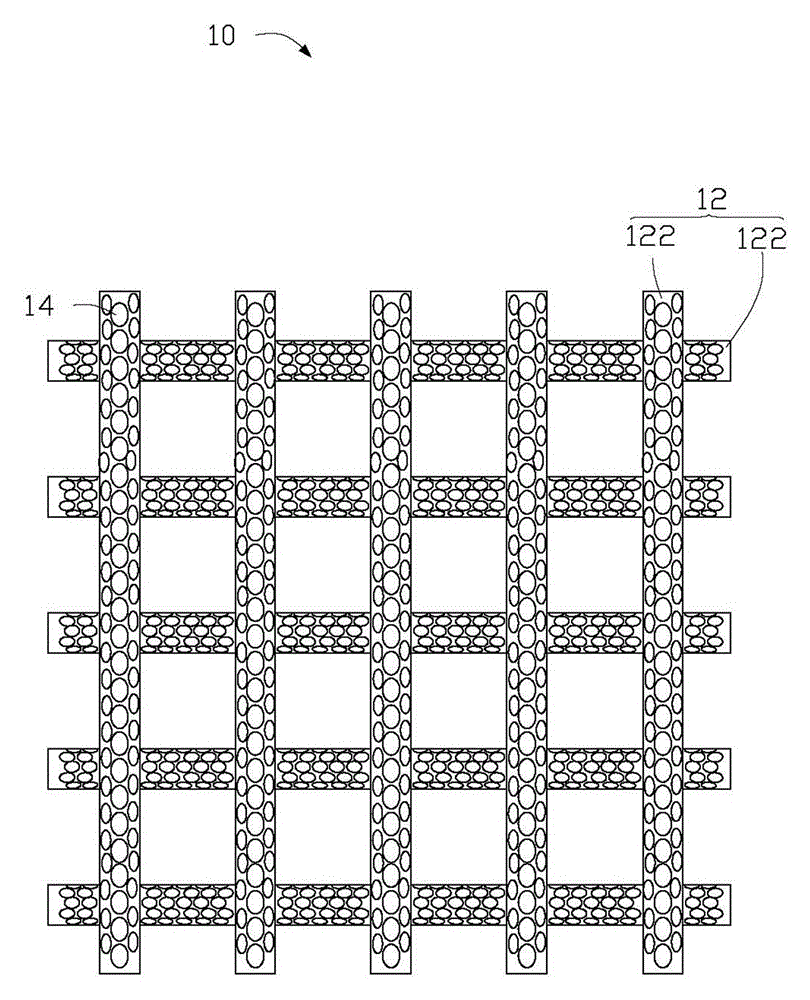

[0035] The preparation method of the positive electrode 10 of the metal-air battery may be: pulling the carbon nanotube film 122 from the carbon nanotube array; loading catalyst particles 14 on the surface of the carbon nanotube film 122 to form a catalyst composite carbon nanotube film; and A plurality of catalyst-composite carbon nanotube films are stacked on each other to form the positive electrode 10 of the metal-air battery. When the positive electrode 10 of the metal-air battery has a positive current collector 16 , the stacking of multiple catalyst-composite carbon nanotube films refers to stacking the catalyst-composite carbon nanotube films on the surface of the positive current collector 16 .

[0036] The method for loading catalyst particles on the surface of the carbon nanotube film may be chemical vapor deposition or physical vapor deposition, such as vacuum evaporation or magnetron sputtering. When the catalyst particles are loaded, the mass percentage of the ca...

Embodiment 1

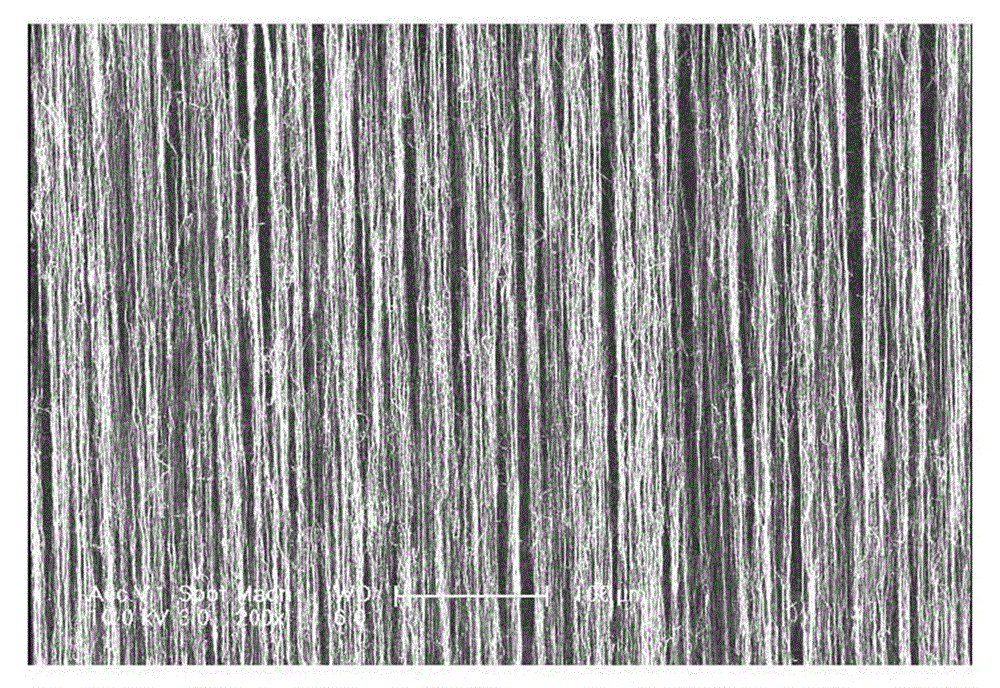

[0043] Carbon nanotube films were obtained by pulling from carbon nanotube arrays. Ru metal particles were formed on the surface of the carbon nanotube film by magnetron sputtering. see Figure 7 , the particle size of Ru particles is about 3nm~5nm, uniformly and dispersedly attached to the tube wall of the carbon nanotube. Laminate 100 layers of carbon nanotube films with Ru metal particles on the surface of the carbon nanotube paper to form the positive electrode of the lithium-air battery. The 100 layers of carbon nanotube films are respectively stacked along directions perpendicular to each other, so that the extending directions of carbon nanotubes in the carbon nanotube network structure are perpendicular to each other. The carbon nanotube paper is obtained by laminating 500 layers of carbon nanotube films, and the thickness of the carbon nanotube paper is about 40 microns. The negative electrode is lithium metal. The electrolyte is 0.1mol / L LiTFSI dissolved in TEGDM...

Embodiment 2

[0045] Carbon nanotube films were obtained by pulling from carbon nanotube arrays. Pd metal particles are formed on the surface of the carbon nanotube film by magnetron sputtering. see Figure 10 , the particle size of Pd particles is about 5nm~10nm, uniformly and dispersedly attached to the tube wall of the carbon nanotube. Laminate 100 layers of carbon nanotube films with Pd metal particles on the surface of the carbon nanotube paper to form the positive electrode of the lithium-air battery. The 100 layers of carbon nanotube films are respectively stacked along directions perpendicular to each other, so that the extending directions of carbon nanotubes in the carbon nanotube network structure are perpendicular to each other. The carbon nanotube paper is obtained by laminating 500 layers of carbon nanotube films, and the thickness of the carbon nanotube paper is about 40 microns. The negative electrode is lithium metal. The electrolyte is 0.1mol / L LiTFSI dissolved in TEGD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com