Binary system quick-drying thick-layer cement self-leveling mortar

A self-leveling mortar and binary system technology, applied in the field of building materials, can solve the problems of prolonged construction period and high cost, and achieve the effects of fast construction speed, high flatness and early strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

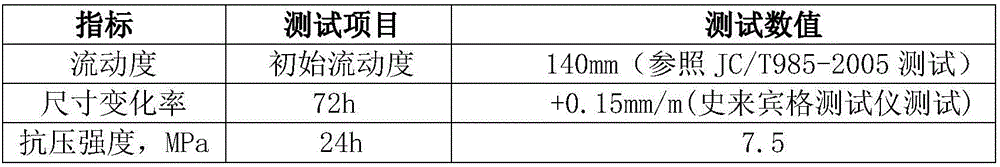

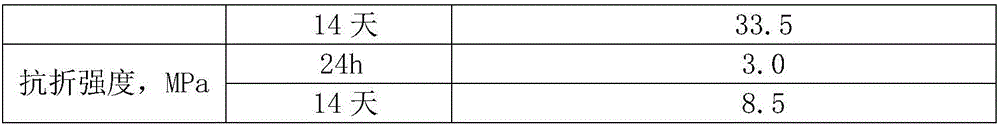

Examples

Embodiment 1

[0033] The binary system quick-drying thick-layer cement self-leveling mortar provided in this example is composed of the following components in mass percentage:

[0034] Ordinary Portland cement 28%,

[0035] Sulfur-aluminum cement 8%,

[0037] Fine Shenzhu 5%,

[0038] 12-140 mesh dried river sand 40%,

[0039] Inert fine filler 15%,

[0040] Superplasticizer 0.2%,

[0041] Wetting tackifier 0.2%,

[0042] Anti-split fibers 0.3%,

[0043] Modified low viscosity cellulose ether 0.05%,

[0044] 0.2% defoamer,

[0045] Retarder 0.05%.

Embodiment 2

[0047] The binary system quick-drying thick-layer cement self-leveling mortar provided in this example is composed of the following components in mass percentage:

[0048] Ordinary Portland cement 30%,

[0049] Sulfur-aluminum cement 6%,

[0051] Fine Shenzhu 4%,

[0052] 12-140 mesh dried river sand 45%,

[0053] Inert fine filler 12%,

[0054] Superplasticizer 0.5%,

[0055] Wetting tackifier 0.05%,

[0056] Anti-split fiber 0.2%,

[0057] Modified low viscosity cellulose ether 0.08%,

[0058] Defoamer 0.1%,

[0059] Retarder 0.1%.

Embodiment 3

[0061] The binary system quick-drying thick-layer cement self-leveling mortar provided in this example is composed of the following components in mass percentage:

[0062] Ordinary Portland cement 30%,

[0063] Sulfur-aluminum cement 5%,

[0065] Fine Shenzhu 2.83%,

[0066] 12-140 mesh dried river sand 44.5%,

[0067] Inert fine filler 15%,

[0068] Superplasticizer 0.2%,

[0069] Wetting tackifier 0.06%,

[0070] Anti-split fiber 0.2%,

[0071] Modified low viscosity cellulose ether 0.06%,

[0072] Defoamer 0.1%,

[0073] Retarder 0.05%.

[0074] The components in the binary system quick-drying thick-layer cement self-leveling mortar provided by the above-mentioned embodiments 1-3 are selected as follows: ordinary Portland cement can be 42.5 ordinary Portland cement or 32.5 ordinary Portland cement; The cement can be fast-hardening sulfoaluminate cement or low-alkalinity sulfoaluminate cement; the calcium oxide is high-purity calcium oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com