Composition used for reducing hydrocarbon oil metal content and its application and method for reducing hydrocarbon oil metal content

A composition and content technology, applied in the refining hydrocarbon oil, petroleum industry and other directions, can solve the problems of only reaching 20-40%, unsatisfactory calcium and iron removal effect, etc., and achieve the effect of reducing metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

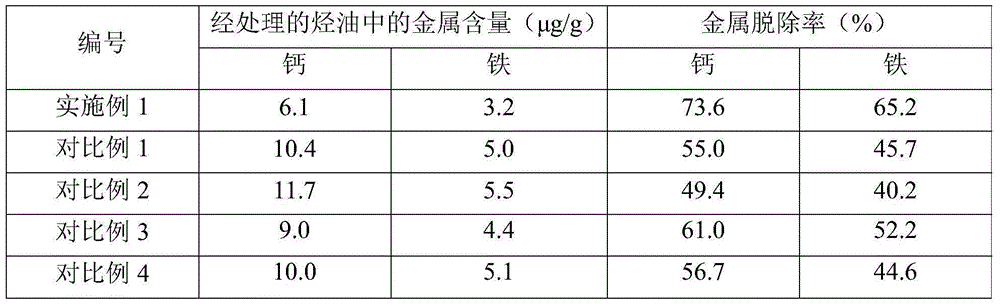

Examples

Embodiment 1

[0064] (1) Atmospheric residual oil (density (20°C) is 0.9621g / cm 3 , wherein the content of calcium is 23.1μg / g, the content of iron is 9.2μg / g) and aminotriacetic acid, 4-tert-butylphenylacetonitrile, xylene, polyoxyethylene-polyethylene oxide with phenolic resin as the initiator Oxypropylene block copolymer (purchased from Shandong Binzhou Chemical Group, the number average molecular weight of polyoxyethylene-polyoxypropylene block copolymer is 12000, based on the total amount of this polyoxyethylene-polyoxypropylene block copolymer , the content of the oxyethylene structural unit is 32% by weight, the content of the oxypropylene structural unit is 68% by weight) and water are stirred evenly. Wherein, based on the weight of atmospheric residual oil, the consumption of aminotriacetic acid is 600 μg / g, the consumption of 4-tert-butylphenylacetonitrile is 1000 μg / g, and the consumption of polyoxyethylene-polyoxypropylene block copolymer is 50 μg / g, relative to 100 parts by we...

Embodiment 2

[0082] (1) The vacuum residue (density (20°C) is 0.9502g / cm 3 , wherein the calcium content is 36.0 μg / g, the iron content is 23.6 μg / g) and hydroxyethylidene diphosphonic acid, 4-isopropylphenylacetonitrile, 180 # Aromatic solvent oil, polyoxyethylene-polyoxypropylene block copolymer (purchased from Shandong Binzhou Chemical Industry Group, the number average molecular weight of polyoxyethylene-polyoxypropylene block copolymer is 13000 with phenolic resin as initiator) Based on the total amount of the polyoxyethylene-polyoxypropylene block copolymer, the content of the oxyethylene structural unit is 35% by weight, and the content of the oxypropylene structural unit is 65% by weight) and stirred with water evenly. Among them, based on the weight of the vacuum residue, the amount of hydroxyethylidene diphosphonic acid is 400 μg / g, the amount of 4-isopropylphenylacetonitrile is 1500 μg / g, and the polyoxyethylene-polyoxypropylene block copolymer The dosage is 100μg / g, relative t...

Embodiment 3

[0101] The hydrocarbon oil was treated in the same manner as in Example 2, except that in step (1), the hydroxyethylidene diphosphonic acid was replaced by an equal weight of acetic acid.

[0102] The experimental results are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com