Preparation and application of phosphate-free type high temperature inhibitor

A high-temperature corrosion inhibitor and solvent technology, which is applied to the preparation and application of phosphorus-free high-temperature corrosion inhibitors, can solve the problems of poor corrosion inhibition effect of non-phosphorus-based corrosion inhibitors, poisoning of processing catalysts, and restrictions on use, and achieves improved performance. Corrosion inhibition effect, strong oxidation resistance, stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

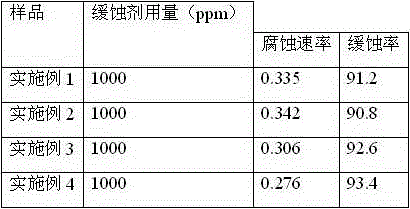

Examples

Embodiment 1

[0021] Example 1: Add 282g of oleic acid and 40g of xylene into a four-neck flask, heat to 80-100°C, keep stirring and add 230g of cyclohexanediamine dropwise, and the dropwise addition is completed within 2 hours; after the dropwise addition is completed, raise the temperature to Heat to 150-180°C, continue to stir for 3-6 hours, dehydrate until the reaction is complete; finally distill off the solvent in the reaction.

[0022] According to the proportion of fatty acid aminoamide 30%, sulfurized isobutylene (T321) 20%, and heavy aromatic solvent oil 50%, it is formulated to make fatty acid aminoamide high temperature corrosion inhibitor.

Embodiment 2

[0023] Example 2: Add 284g of stearic acid and 30g of toluene into a four-neck flask, heat to 100-120°C, stir continuously and add 345g of cyclohexanediamine dropwise, and the dropwise addition is completed within 3 hours; after the dropwise addition is completed, raise the temperature to To 180~200℃, continue to stir for 3~6 hours, dehydrate until the reaction is complete; finally distill off the solvent in the reaction.

[0024] According to the proportion of fatty acid aminoamide 35%, sulfurized isobutylene (T321) 25%, and heavy aromatic solvent oil 40%, it is formulated to make fatty acid aminoamide high temperature corrosion inhibitor.

Embodiment 3

[0025] Example 3: Add 200g of lauric acid and 40g of xylene into a four-necked flask, heat to 80-100°C, keep stirring and add 230g of methylcyclopentadiamine dropwise, and the dropwise addition is completed within 2 hours; after the dropwise addition is completed, the The temperature rises to 160-180°C, and the stirring is continued for 3-5 h, dehydration until the reaction is complete; finally, the solvent in the reaction is distilled off.

[0026] According to the proportion of fatty acid aminoamide 30%, sulfurized isobutylene (T321) 25%, and heavy aromatic solvent oil 45%, it is formulated to make fatty acid aminoamide high temperature corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com