Isomorphous cobaltosic oxide@cobaltosic oxide nuclear shell structure material and preparation method and application thereof

A technology of tricobalt tetroxide and core-shell structure, which is applied in the manufacture of hybrid/electric double layer capacitors and hybrid capacitor electrodes, etc., can solve the problems of poor electrochemical properties of electrode materials, and achieve the effects of easy regulation, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing isomorphic cobalt tetroxide@cobalt tetroxide core-shell structure material, comprising:

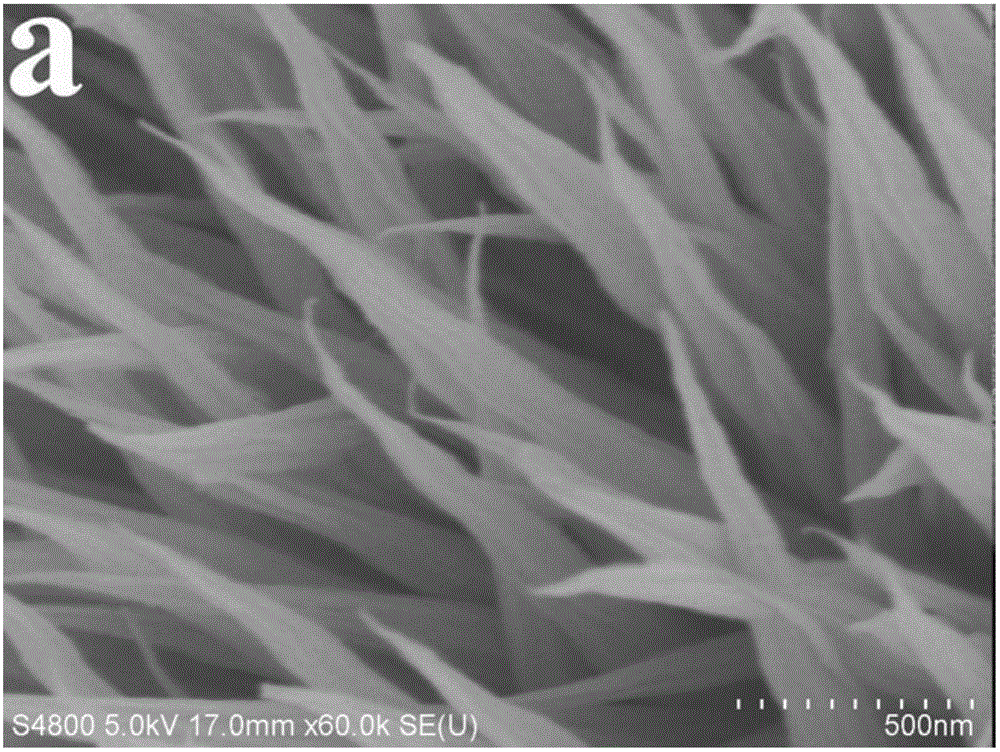

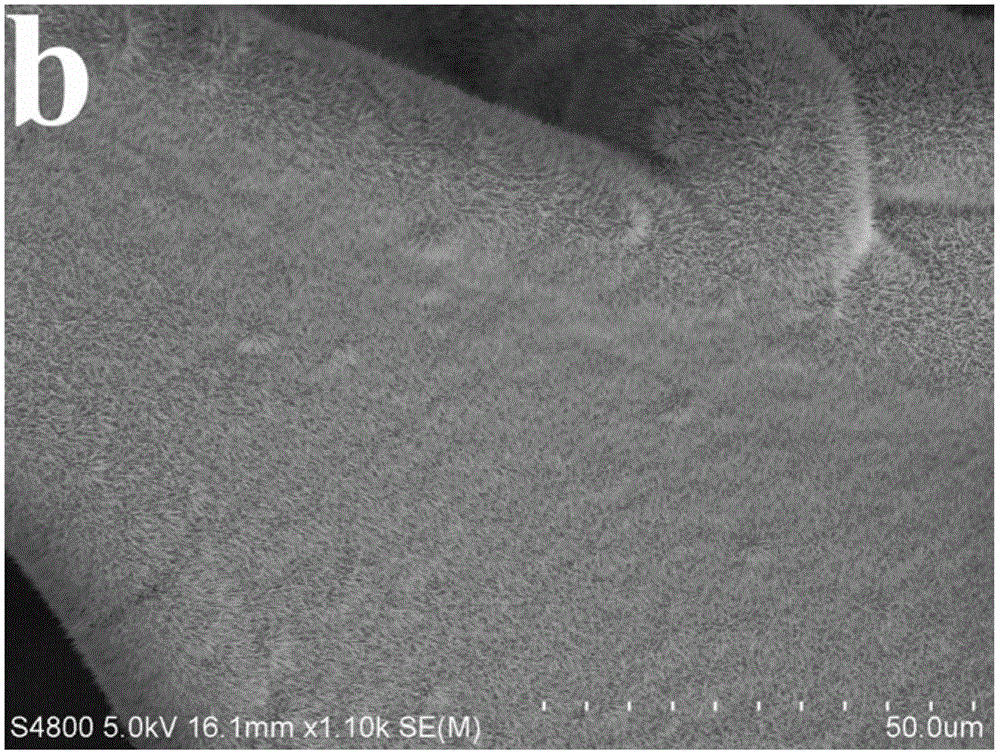

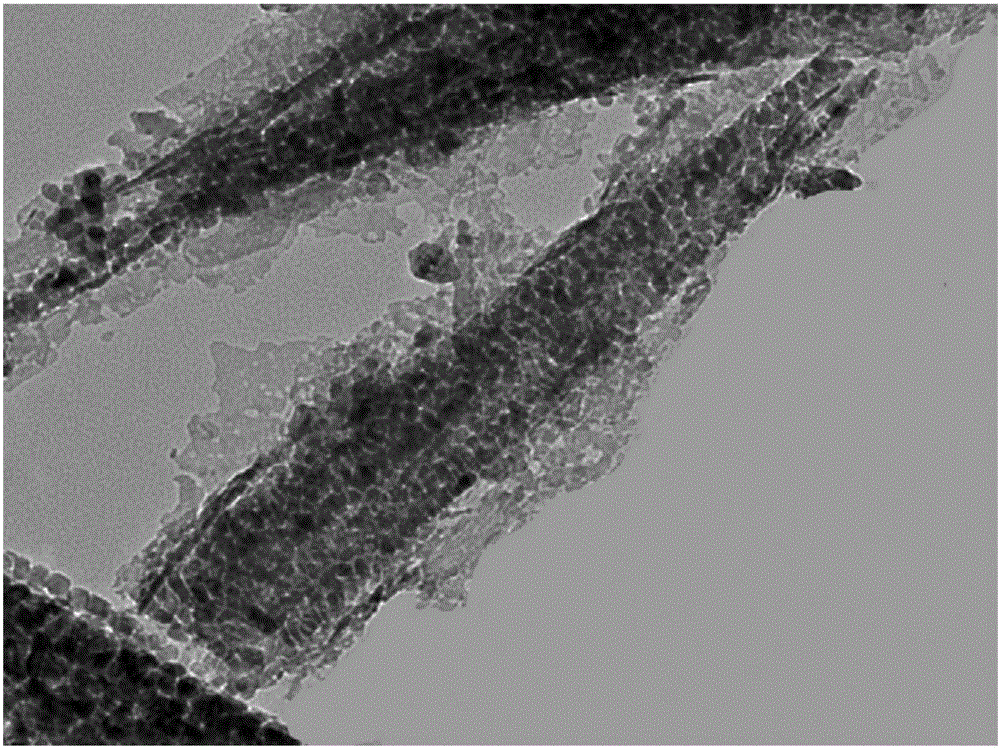

[0025] 1) Contact reaction of soluble cobalt salt, amine fluoride, urea, water and nickel foam, cleaning, drying and annealing to obtain basic Co 3 o 4 monomer;

[0026] 2) Hexamethylenetetramine, soluble cobalt salt, ethanol, water and basic Co 3 o 4 The monomer is hydrothermally reacted, washed, dried, and annealed to obtain isomorphic cobalt tetroxide@cobalt tetroxide core-shell structure material.

[0027] In step 1) of the above preparation method, the amount of each material can be selected in a wide range, but in order to make the prepared core-shell structure material have more excellent specific capacitance and cycle stability, preferably, in step 1) In, relative to the soluble cobalt salt of 1.0-3.0mmol, the consumption of amine fluoride is 3.0-5.0mmol, and the consumption of urea is 8-12mmol; More preferably, relative to ...

Embodiment 1

[0037] 1) Stir 2mmol of cobalt chloride, 4mmol of ammonium fluoride, 10mmol of urea and 30mL of deionized water into the reaction kettle, then add a piece of nickel foam (0.2-0.3g) treated with hydrochloric acid into the kettle and place in React at 100°C for 10h, wash, dry at 60°C for 12h, and anneal at 320°C for 2h to obtain the basic Co 3 o 4 monomer;

[0038] 2) the above basic Co 3 o 4 Monomer (0.4mmol), 1.5mmol hexamethylenetetramine and 0.5mmol cobalt nitrate were added to 20mL deionized water and 10mL ethanol and stirred into a uniform solution, then the above mixed system was transferred to the reaction kettle at 90 React at ℃ for 12 hours, take it out after cooling, wash with deionized water and absolute ethanol three times respectively, dry at 60℃, and anneal at 320℃ for 3h, then the isomorphic tricobalt tetroxide@cobalt tetraoxide core-shell structure material A1 can be obtained.

Embodiment 2

[0040] 1) Stir 2.5mmol of cobalt chloride, 4.5mmol of ammonium fluoride, 10.5mmol of urea and 35mL of deionized water into the reaction kettle, then add a piece of nickel foam (0.2-0.3g ) and react at 110°C for 9h, wash, dry at 60°C for 12h, and anneal at 340°C for 2h to obtain the basic Co 3 o 4 monomer;

[0041] 2) the above basic Co 3 o 4 Monomer (0.5mmol), 1.7mmol hexamethylenetetramine and 0.7mmol cobalt nitrate were added to 30mL deionized water and 10mL ethanol and stirred into a uniform solution, then the above mixed system was transferred to the reaction kettle at 100 React at ℃ for 10 hours, take it out after cooling, wash with deionized water and absolute ethanol three times respectively, dry at 60℃, and anneal at 300℃ for 3 hours to prepare the isomorphic tricobalt tetroxide @ tricobalt tetroxide core-shell structure material A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com