A preparation method of high-efficiency visible light degradation agent nanosheet in2.77s4

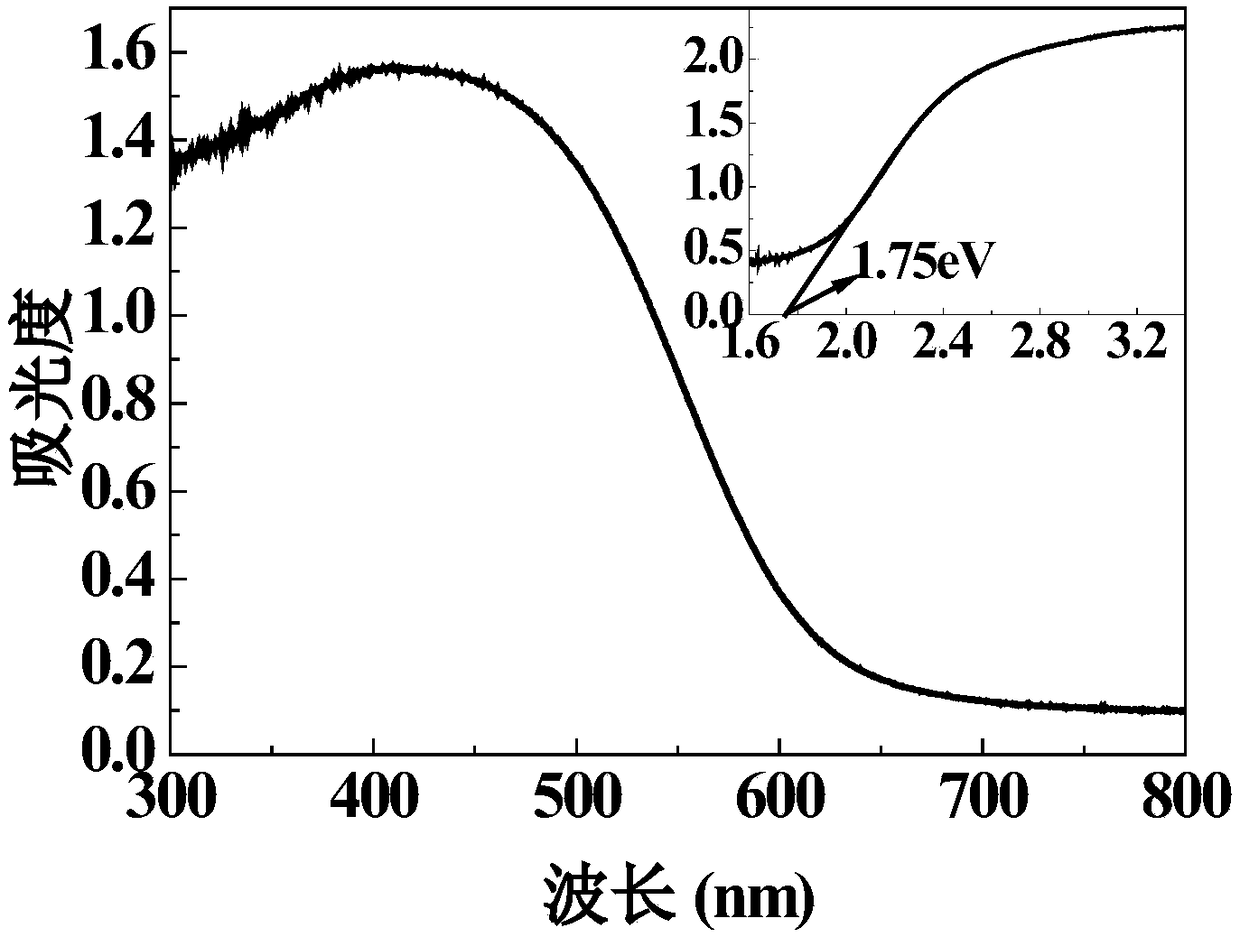

A nano-flaky, visible light technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, light water/sewage treatment, etc., can solve the problems of organic matter and heavy metal pollution, complex synthetic methods of degradants, and low preparation efficiency, and achieve High degradation efficiency, excellent photoresponse effect, and small band gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Weigh an appropriate amount of In(NO 3 ) 3 4.5H 2 O (Sinopharm Chemical Reagent Co., Ltd., the same below), thioacetamide (Sinopharm Chemical Reagent Co., Ltd., the same below) were fully dissolved in deionized water, and then placed in a polytetrafluoroethylene-lined hydrothermal reaction kettle ; Wherein, the indium ion concentration is 0.05mol / L, and the molar ratio of indium and sulfur is 1:3.

[0023] 2. Control the hydrothermal reaction temperature to 180°C and the reaction time to 14 hours. After the reaction, the reaction kettle is naturally cooled to room temperature.

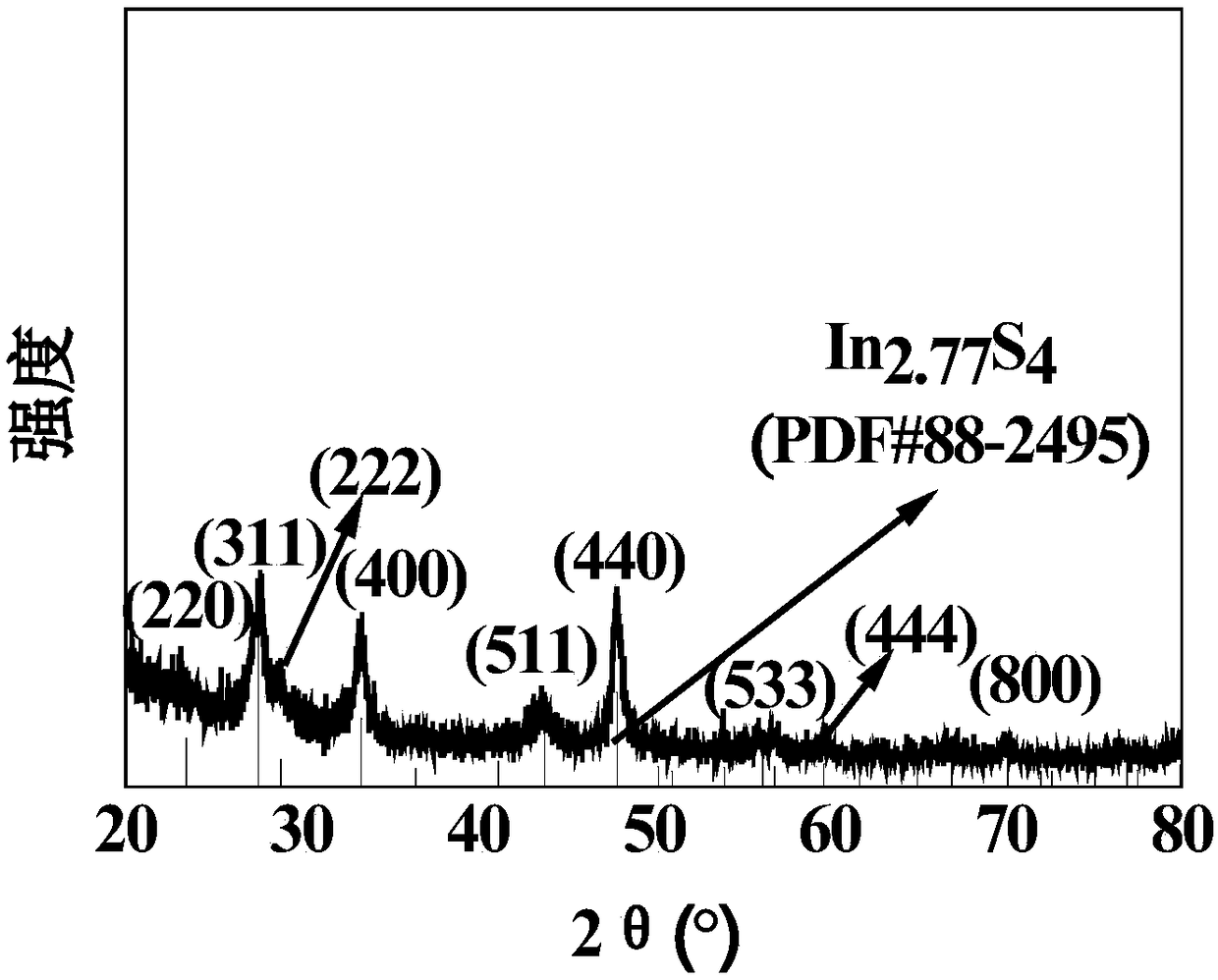

[0024] 3. Take the product in step 2 out of the reaction kettle, repeatedly wash and filter with deionized water until neutral, and then dry to obtain a powder In 2.77 S 4 .

[0025] 4. Weigh 0.05g of In 2.77 S 4 Products were respectively placed in 10mg / L rhodamine B solution, 10mg / L methyl orange solution, and 70mg / L potassium dichromate solution, and were subjected to photocatalytic...

Embodiment 2

[0027] 1. Weigh an appropriate amount of In(NO 3 ) 3 4.5H 2 O, thioacetamide is fully dissolved in deionized water, and then placed in a hydrothermal reaction kettle lined with polytetrafluoroethylene; wherein, the indium ion concentration is 0.05mol / L, and the molar ratio of indium and sulfur is 1: 4.

[0028] 2. Control the hydrothermal reaction temperature to 180°C and the reaction time to 15 hours. After the reaction, the reaction kettle is naturally cooled to room temperature.

[0029] 3. Take the product in step 2 out of the reaction kettle, wash it repeatedly with deionized water, filter it until it is neutral, and then dry it to obtain a powder In 2.77 S 4 .

[0030] 4. Weigh 0.05g of In 2.77 S 4 Products were respectively placed in 10mg / L rhodamine B solution, 10mg / L methyl orange solution, and 70mg / L potassium dichromate solution, and were subjected to photocatalytic degradation experiments under 300W xenon lamp irradiation. Use filters to filter out UV light...

Embodiment 3

[0033] 1. Weigh an appropriate amount of In(NO 3 ) 3 4.5H 2 O, thioacetamide is fully dissolved in deionized water, and then placed in a hydrothermal reaction kettle lined with polytetrafluoroethylene; wherein, the indium ion concentration is 0.05mol / L, and the molar ratio of indium and sulfur is 1: 5.

[0034] 2. Control the hydrothermal reaction temperature to 180°C and the reaction time to 14 hours. After the reaction, the reaction kettle is naturally cooled to room temperature.

[0035] 3. Take the product in step 2 out of the reaction kettle, repeatedly wash and filter with deionized water until neutral, and then dry to obtain a powder In 2.77 S 4 .

[0036] 4. Weigh 0.05g of In 2.77 S 4 Products were respectively placed in 10mg / L rhodamine B solution, 10mg / L methyl orange solution, and 70mg / L potassium dichromate solution, and were subjected to photocatalytic degradation experiments under 300W xenon lamp irradiation. Use filters to filter out UV light. The exper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com