Mn base metal organic skeletal catalyst, and preparation method and application thereof in air pollution prevention

An organic framework and catalyst technology, applied in the field of metal-organic framework catalytic materials, can solve problems such as difficult to achieve complete conversion, difficult to industrial application, and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

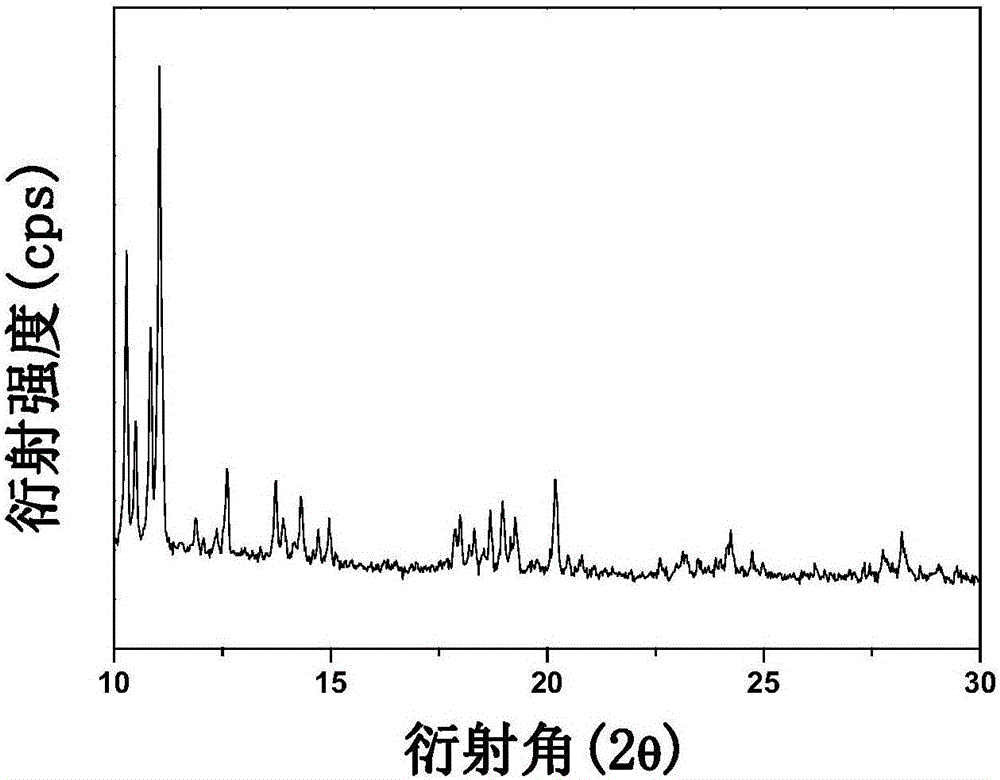

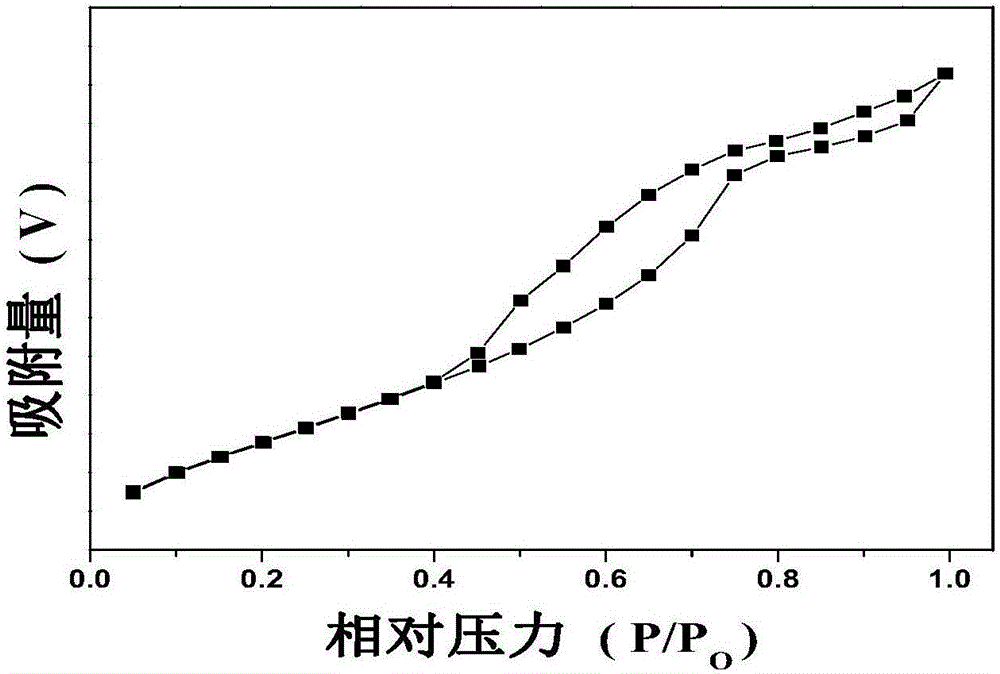

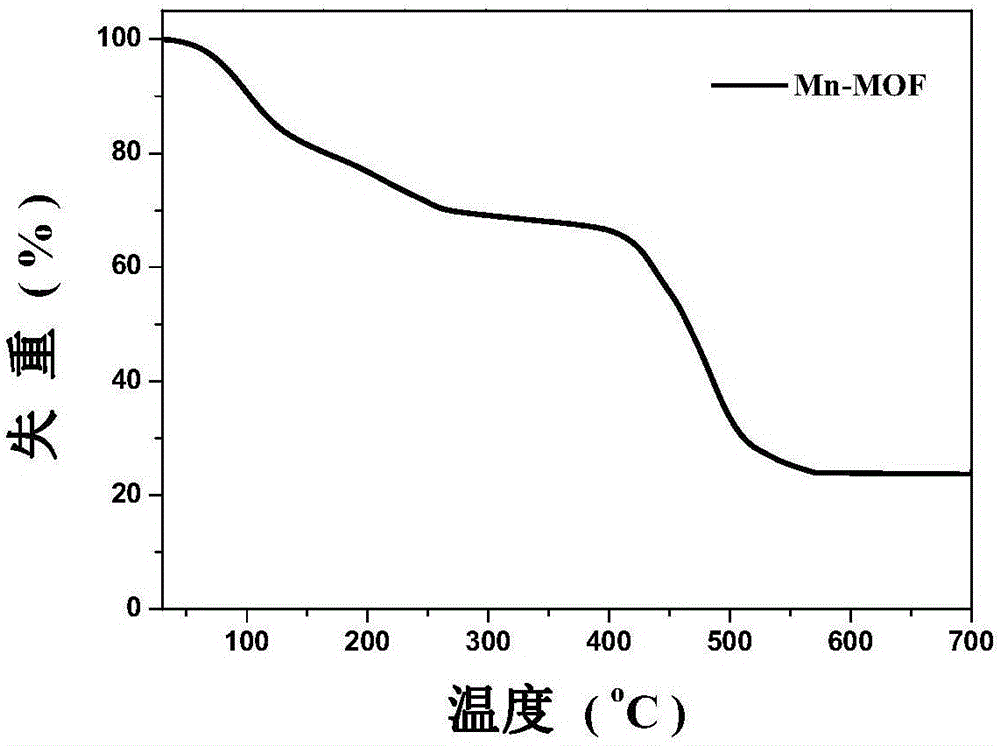

[0024] A preparation method of Mn-based metal organic framework catalyst includes the following steps:

[0025] Step 1. Take 5ml of methanol solution with a graduated cylinder and place it in a 50ml beaker, and weigh 2.5g of manganese nitrate tetrahydrate (Mn(NO 3 ) 2 ·4H 2 O) Dissolve in the above beaker containing 5 ml methanol solution, stir until completely dissolved, and obtain a methanol solution of manganese nitrate.

[0026] Step 2: Dissolve the methanol solution of manganese nitrate in the methanol solution of homotricarboxylic acid, and heat the reaction for 0.5 h while stirring to obtain the reacted solution;

[0027] Step 3: Put the reacted solution in a reaction kettle lined with polytetrafluoroethylene, seal it, put it in an oven at a temperature of 120°C and heat it for 2 hours to obtain coarse crystals, filter and wash the coarse crystals, Dry for 8 hours in an oven at a temperature of 80° C. to obtain crystals.

[0028] Step four, put the crystal obtained in step thre...

Embodiment 2

[0041] A preparation method of Mn-based metal-organic framework catalyst. The preparation method is the same as in Example 1. The calcination temperature in step 4 is changed to 100°C (atmosphere volume ratio is 1% CO, 20% O 2 , 79% He). The evaluation method of the Mn-based metal-organic framework catalyst prepared in this example is the same as that of Example 1. The activity test shows that the Mn-based metal-organic framework catalyst prepared in this embodiment has a CO conversion rate of 100% at 360°C.

Embodiment 3

[0043] A preparation method of Mn-based metal-organic framework catalyst. The preparation method is the same as in Example 1. The calcination temperature in step 4 is changed to 200°C (atmosphere volume ratio is 1% CO, 20% O 2 , 79% He). The evaluation method of the Mn-based metal-organic framework catalyst prepared in this example is the same as that of Example 1. The activity test shows that the Mn-based metal-organic framework catalyst prepared in this example has a CO conversion rate of 100% at 330°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com