Bilayer active medium material and preparation method and application method thereof

A technology of medium materials and active materials, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., to achieve high oxygen release rate, prolonged oxygen release time, and low oxygen release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

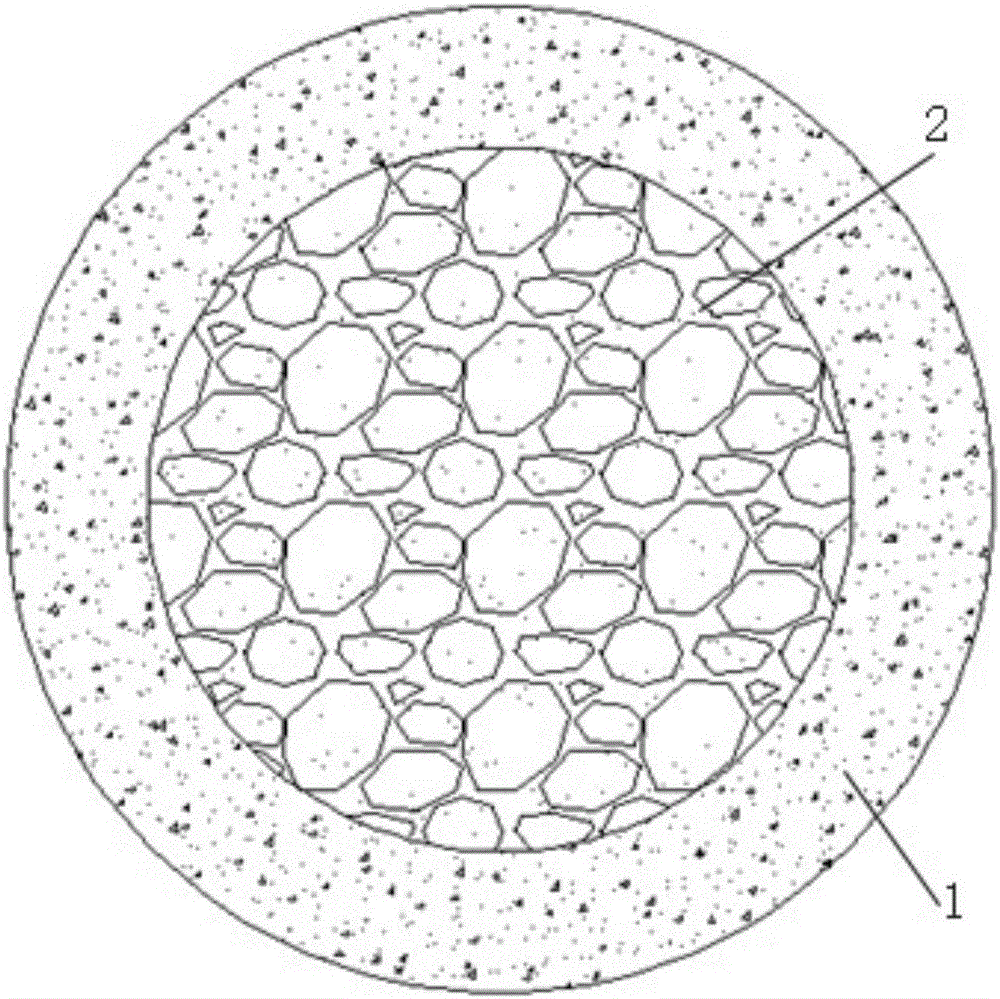

Image

Examples

preparation example Construction

[0042] The method for preparing the above-mentioned double-layer active medium material provided by the present invention adopts two sets of molds to distribute and shape the inner and outer layer materials, and the main steps are:

[0043] 1) Preparation of ferromanganese oxidizing microbial bacterial liquid: Inoculate Pseudomonas putida, Phytophthora spp., and Bacillus into half-strength LB medium at a weight ratio of 1:0.5-1:0.2-0.5 to activate for 1 day , inoculated into a growth medium containing ferrous manganese to acclimatize until a brown-black precipitate is produced, and then inoculated into an expansion medium to expand culture to obtain a composite bacterial liquid. The medium was sterilized before use.

[0044] 2) Prepare the inner layer material: the mass fraction is 10%-30% oxygen-releasing compound, 10%-20% cement, 5%-15% high permeability material, 10%-30% potassium dihydrogen phosphate, 25%- Mix 45% ammonium sulfate and 4%-8% trace elements evenly;

[0045...

Embodiment 1

[0051] 1) Preparation of ferromanganese oxidizing microbial bacterial liquid: inoculate 0.5g of Pseudomonas putida, 0.4g of Phytophthora spp. Shake at 120rpm in a constant temperature shaking box at 28°C for 1 day, absorb 25mL of bacterial liquid and add it to a conical flask containing 500mL growth medium for acclimatization, place it in a constant temperature shaking box at 28°C and shake at 150rpm until brown-black precipitation occurs, draw 25mL of bacterial liquid to Put 500mL conical flask of expansion medium in a constant temperature shaking box at 28°C at 150rpm and shake for 2 days to obtain a composite bacterial solution.

[0052] The half-strength LB medium is 5g tryptone, 2.5g yeast extract, 5g NaCl dissolved in 1L water, and the growth medium is 1g MnCO 3 , 1gFeCl 2 , 0.15g Fe(NH 4 )(SO 4 ) 2 , 0.075g yeast extract, 0.15g sodium citrate, 0.05gNa 4 P 2 o 7 10H 2 O was dissolved in 1L water, and the expansion medium was 0.5g yeast extract, 0.5g acid hydrolyz...

Embodiment 2

[0059] 1) Preparation of ferromanganese oxidizing microbial bacterial liquid: Inoculate 0.7g of Pseudomonas putida, 0.5g of Phytophthora spp., and 0.4g of Bacillus into an Erlenmeyer flask containing 100mL of half-strength LB medium, and place in Shake at a speed of 120rpm in a constant temperature shaking box at 28°C for 1 day, absorb 25mL of bacterial liquid and add it to an Erlenmeyer flask containing 500mL growth medium for acclimatization, place it in a constant temperature shaking box at 28°C and shake at 150rpm until a brown-black precipitate is produced, draw 25mL Put the bacterial liquid into a 500mL Erlenmeyer flask of expansion medium, place it in a constant temperature shaking box at 28°C and shake it at 150rpm for 2 days, and obtain a composite bacterial liquid.

[0060] The half-strength LB medium is 5g tryptone, 2.5g yeast extract, 5g NaCl dissolved in 1L water, and the growth medium is 1g MnCO 3 , 1gFeCl 2 , 0.15g Fe(NH 4 )(SO 4 ) 2 , 0.075g yeast extract, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com