Additive for maintaining construction performance of wet mixing mortar and preparation method thereof

A technology of construction performance and wet-mixed mortar, which is applied in the field of building materials, can solve the problems of unfavorable wet-mixed mortar production and construction quality control, inconsistency between construction performance and construction operable time, and short construction operable time. To achieve the effect of being conducive to production quality control, good water retention performance, and improving construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

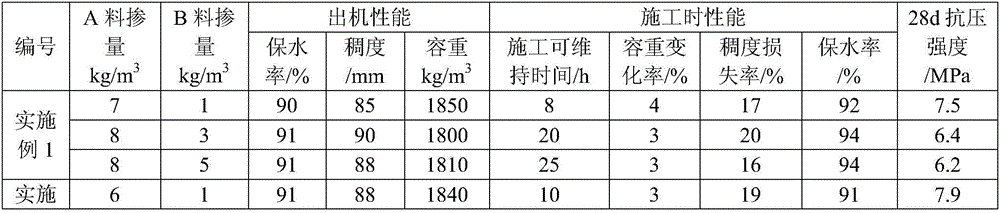

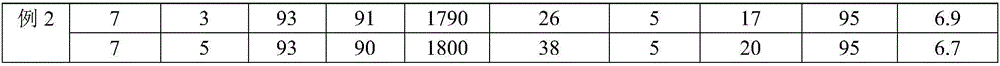

Examples

Embodiment 1~5

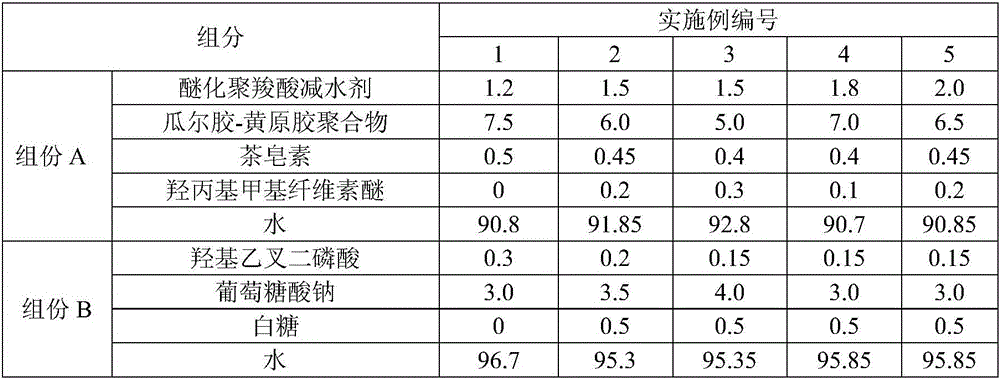

[0023] The raw material formula of the admixture described in Examples 1 to 5 to maintain the construction performance of wet-mixed mortar is shown in Table 1 (parts by mass)

[0024] The formula of each component of the admixture described in Examples 1 to 5 to maintain the construction performance of wet-mixed mortar

[0025]

[0026] The etherified polycarboxylate water reducer has a molecular weight of 50,000 Da, a water reducing rate of 30%, and a solid content of not less than 50 wt%.

[0027] The guar gum-xanthan gum polymer is formed by polymerizing guar gum powder and xanthan gum powder at a mass ratio of 3:2, with a molecular weight of 200,000 Da.

[0028] The tea saponin is a yellow-brown powder with a chemical purity of 90% and an ignition residue of 10%.

[0029] The hydroxypropyl methylcellulose ether is a white powder, easily soluble in water, with a viscosity of 100,000 MPa·S and an ignition residue of 1%.

[0030] The hydroxyethylidene diphosphonic acid i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com