Preparing method of emulsifier Span-80 for emulsion explosive

A technology of span-80, emulsion explosive, applied in non-explosive/non-thermal agent components, explosives, organic chemistry, etc., can solve the problems of high sorbitol sugar residue and carbon residue, lower production efficiency, different yields, etc. The effect of reducing sorbitol residue, increasing product volume and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 (comparative group)

[0016] The process includes the following steps:

[0017] (1) The 450kg sorbitol solution is heated to 130~140℃, free water is removed, and sorbitol is generated;

[0018] (2) The etherification reaction of sorbitol and catalyst occurs at 130-150°C under vacuum, and the reaction time is 3 hours to generate sorbitan anhydride;

[0019] (3) Raise 750kg oleic acid to 100~180℃ for refining to generate essential oleic acid;

[0020] (4) Put essential oleic acid and sorbitan anhydride into the reaction kettle with an acid alcohol molar ratio of 450:740. After adding an alkaline catalyst, first heat the reaction at 180~190℃ for 2 hours, and then keep the temperature at 210~220℃ Esterification reaction for 3 hours;

[0021] (5) Vacuum dehydration and esterification of the above-mentioned reacted materials for 1.5 hours to obtain a crude product;

[0022] (6) Move the crude product into the precipitation tank, and perform cooling and precipitation under heat...

Embodiment 2

[0024] The process includes the following steps:

[0025] (1) Raise 400kg sorbitol solution to 130~140℃ to remove free water to generate sorbitol;

[0026] (2) Under vacuum, sorbitol and catalyst will undergo etherification reaction at 130~150℃. The reaction time is 3 hours to produce sorbitan anhydride. The catalyst used is phosphoric acid and the amount of phosphoric acid added is sorbitol. 0.5% of quality;

[0027] (3) Raise 740kg of oleic acid to 100~180℃ for refining to generate essential oleic acid;

[0028] (4) Put essential oleic acid and sorbitan anhydride into the reaction kettle with an acid alcohol molar ratio of 450:740. After adding an alkaline catalyst, first heat the reaction at 180~190℃ for 2 hours, and then keep the temperature at 210~220℃ The esterification reaction is 3 hours, the basic catalyst used is sodium hydroxide, and the addition amount of the basic catalyst is 0.3% of the total mass of sorbitan anhydride and essential oleic acid;

[0029] (5) Vacuum dehydr...

Embodiment 3~ Embodiment 4

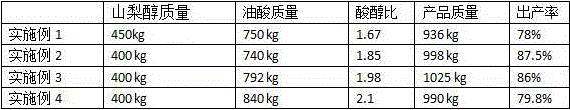

[0032] The difference between Examples 3 to 4 and Example 2 lies in the different qualities of the raw materials used, sorbitol and oleic acid, as shown in the following table.

[0033]

[0034] It can be seen from the above table that when the mass ratio of oleic acid to sorbitol is 1.85 to 1.98, the yield is the highest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com