System and method for producing chili oil

A production system and technology of chili oil, applied in the direction of fat oil/fat production, fat production, essential oil/spices, etc., can solve the problems that the quality index is difficult to meet the user's requirements, the loss of active ingredients is large, and the application of chili oil is restricted. Shorten the extraction time, improve the quality and aroma, and reduce the effect of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

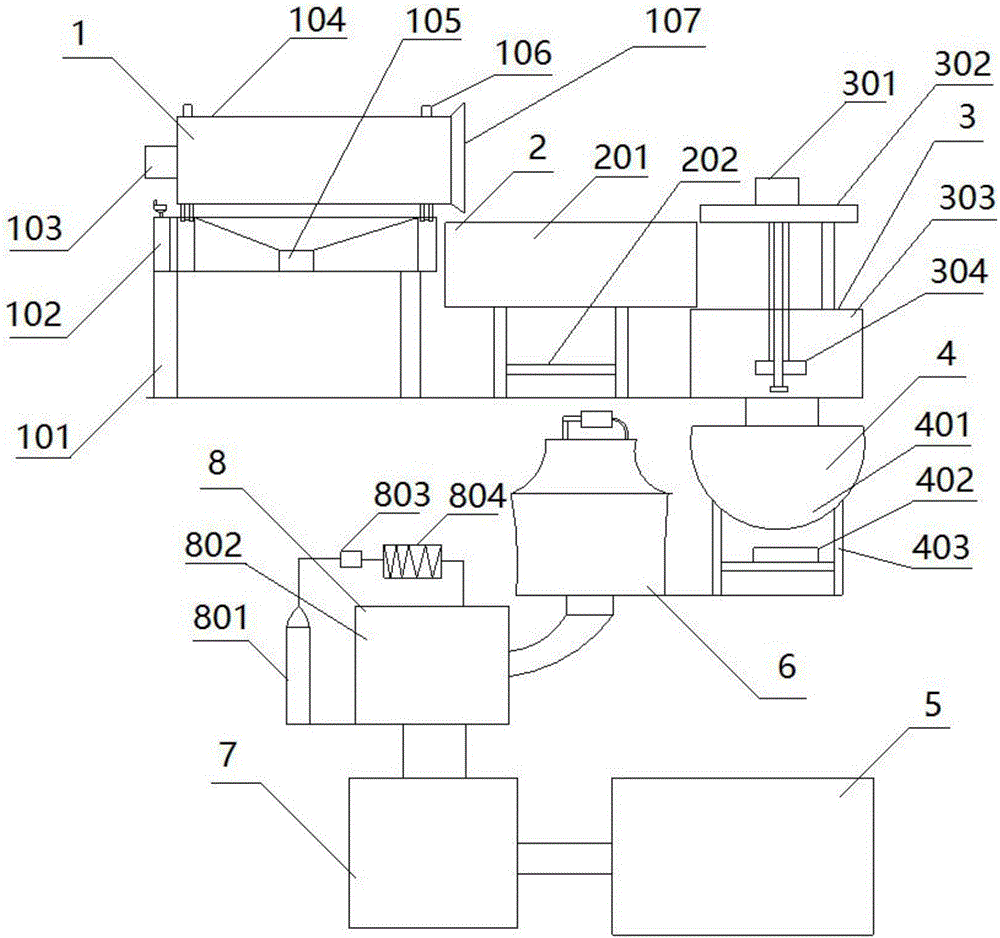

[0038] Such as figure 1 As shown, a chili oil production system includes a frying device 1, a spreading device 2, a crushing device 3, a frying device 4, an ultrasonic device 6, a rectifying device 5, an extraction device 8 and a separation device 7.

[0039] Described frying device 1 comprises speed regulating mechanism 102, electric furnace 105, drum 104, support 101, roller 106, feed inlet 103 and discharge port 107, and speed regulating mechanism 102 is installed on the support 101, and cylinder 104 is installed on the speed regulating device. On the roller 106 of the mechanism 102 , the electric furnace 105 is installed on the support 101 , and the feed port 103 and the discharge port 107 are respectively installed on both sides of the drum 104 .

[0040] Described airing device 2 comprises support frame 202 and airing groove 201, and airing groove 201 is installed on the supporting frame 202, and ventilation hole is installed at the bottom of airing groove 201, and the s...

Embodiment 2

[0046] Production method of chili oil:

[0047] (1) Stir-frying: Cut the selected red dried chili into 3cm-long pepper segments, and then put them into the frying device for frying. The temperature is adjusted to 120°C, the rotating speed of the drum is 100r / min, and the frying time is 30min. ;

[0048] (2) airing: put the fried pepper into the airing device and air it in the air, adjust the temperature to 20°C, the relative humidity to 40%, and the time to be 10min;

[0049] (3) Pulverizing: the chilli after airing is sent into the pulverizing device and pulverized, and the obtained fineness is 30 order chili powder;

[0050] (4) Frying: send chili powder into the frying device for frying, the temperature of frying is 180°C, and the time is 10min;

[0051] (5) Ultrasonic treatment: send the fried chili powder into an ultrasonic device for ultrasonic treatment, control the ultrasonic power to 50w, and the treatment time is 20min;

[0052] (6) Extraction: Send the ultrasonic...

Embodiment 3

[0058] (1) Stir-frying: cut the selected red dried chili into 5cm-long pepper segments, and then put them into the frying device for frying. The temperature is adjusted to 180°C, the rotating speed of the drum is 300r / min, and the frying time is 50min. ;

[0059] (2) airing: send the fried peppers into the airing device and airing, the temperature is adjusted to 40°C, the relative humidity is 60%, and the time is 30min;

[0060] (3) pulverizing: the capsicum after airing is sent into pulverizing device to pulverize, and obtaining fineness is 50 order capsicum powder;

[0061] (4) Frying: send chili powder into the frying device for frying, the temperature of frying is 240°C, and the time is 20min;

[0062] (5) Ultrasonic treatment: send the fried paprika into an ultrasonic device for ultrasonic treatment, control the ultrasonic power to 300w, and the treatment time is 40min;

[0063] (6) Extraction: Send the ultrasonically treated chili powder into the extraction device, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com