Method for preparing CuCr contact materials by means of vacuum self-consuming arc melting

A vacuum consumable arc and contact material technology, which is applied in the field of alloy material preparation, can solve the problems of high oxide content of materials, large pores in microstructure, etc., and achieve reduced gas content, uniform microscopic metallographic distribution, and cooling speed inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

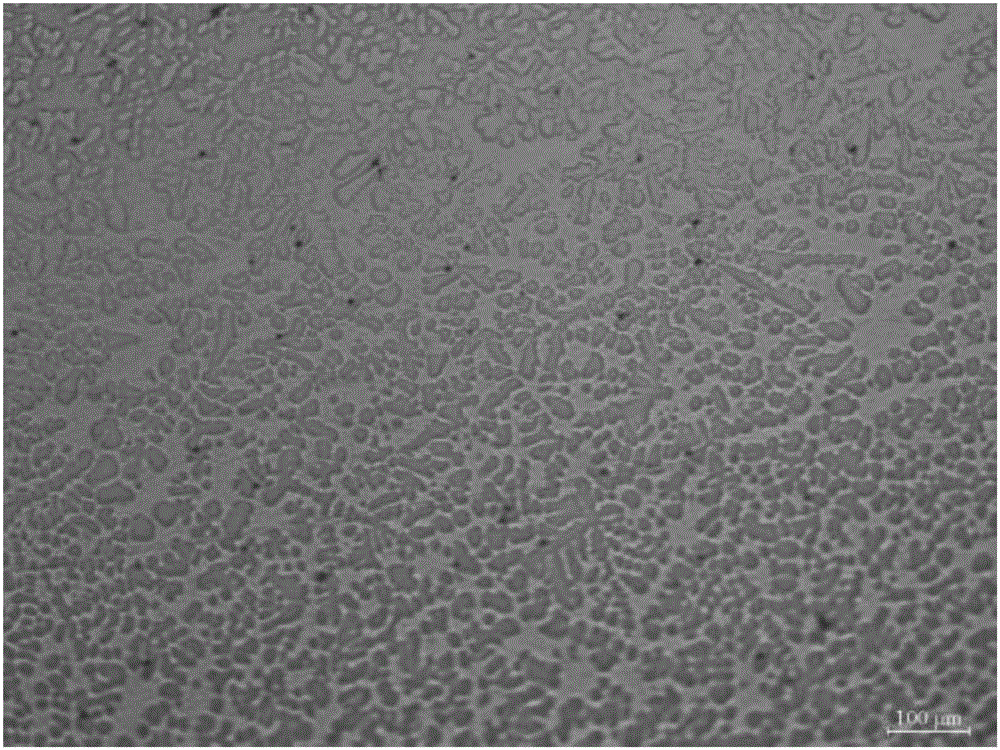

Examples

Embodiment 1

[0027] The method for preparing CuCr contact material by vacuum consumable arc melting comprises the following steps:

[0028] (1) Mix copper powder and Cr powder according to the ratio Cu(wt%):Cr(wt%)=70(wt)%:30(wt)% in the mixer for 2h-5h, and add them at the same time when mixing Mix half the weight of Cr powder and copper powder for 2 hours, then add the remaining Cr powder and copper powder at the same time, and mix for another 2 hours evenly;

[0029] (2) Under the pressure of 220Mpa in the cold isostatic press, press out the alloy bar stock of length L=800mm, outer diameter d=70, holding time 8min;

[0030] (3) followed by sintering at a temperature of 700° C. in a vacuum sintering furnace for 12 hours;

[0031] (4) Smelting the sintered bars in a vacuum consumable furnace. After closing the furnace door, the vacuum consumable furnace is evacuated, and then filled with an inert protective gas for smelting. The pressure of the inert gas is 150mbar, and the melting curre...

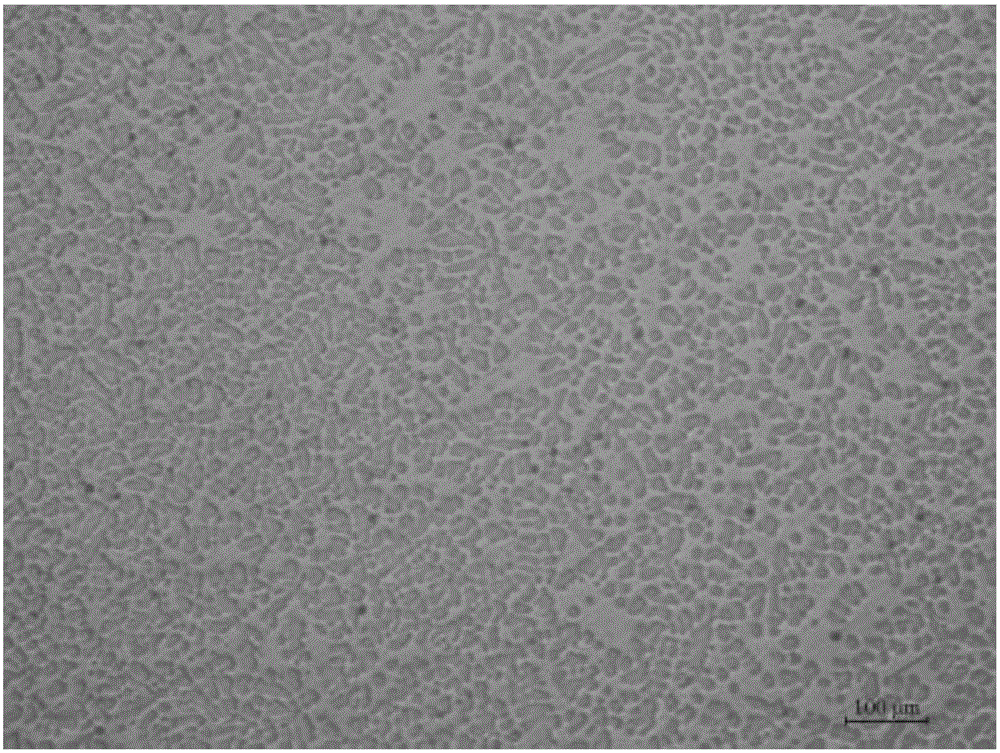

Embodiment 2

[0036] The method for preparing CuCr contact material by vacuum consumable arc melting comprises the following steps:

[0037] (1) Mix copper powder and Cr powder according to the ratio Cu(wt%):Cr(wt%)=65(wt)%:35(wt)% in the mixer for 2h-5h, add half of them respectively when mixing Weight of Cr powder and copper powder, mix for 2 hours, then add the remaining Cr powder and copper powder at the same time, and mix for another 2 hours evenly;

[0038] (2) Under the pressure of 220Mpa in the cold isostatic press, press out the alloy bar stock of length L=800mm, outer diameter d=70, hold pressure time 2min;

[0039] (3) followed by sintering at a temperature of 900° C. in a vacuum sintering furnace for 15 hours;

[0040] (4) Smelting the sintered bars in a vacuum consumable furnace. After closing the furnace door, the vacuum consumable furnace is evacuated, and then the furnace is filled with an inert protective gas for smelting. The protective gas pressure is 180mbar. The curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com