Aluminum plastic compound film with excellent heat sealing property and low-temperature flexibility

An aluminum-plastic composite film and low-temperature toughness technology, applied in the field of aluminum-plastic composite film, can solve the problems of narrow heat-sealing window, poor heat-sealing strength, insufficient low-temperature toughness, etc., and achieve a wide heat-sealing temperature range and low heat-sealing lower limit temperature. , The effect of low initial heat sealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

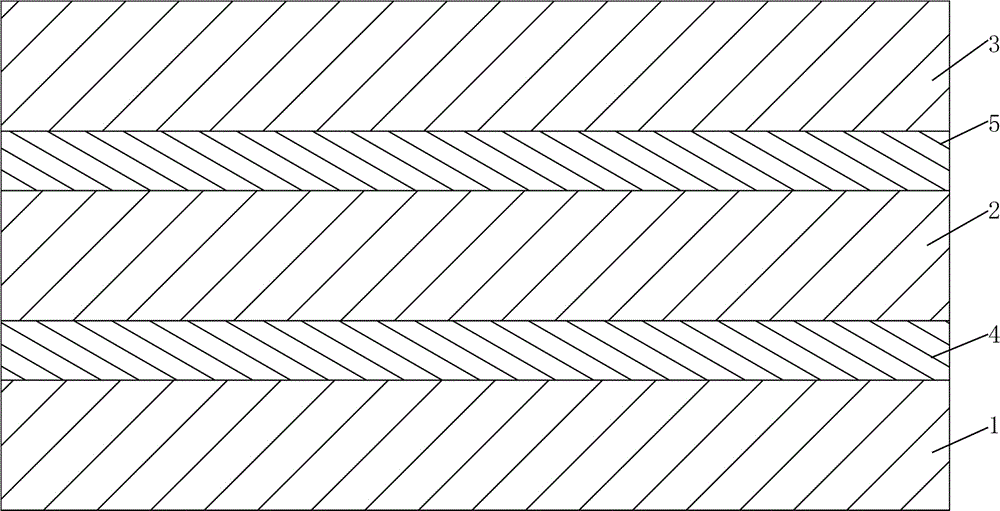

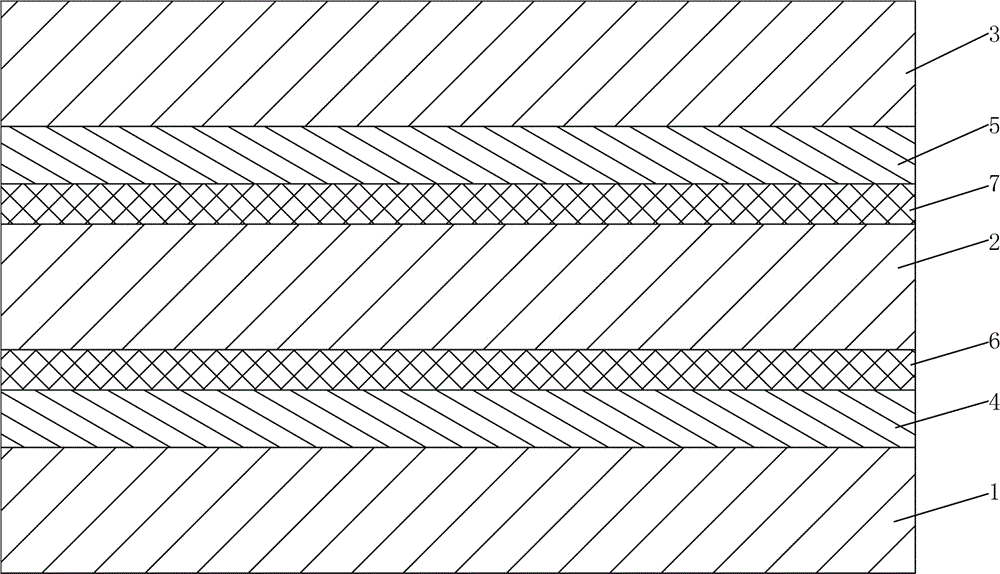

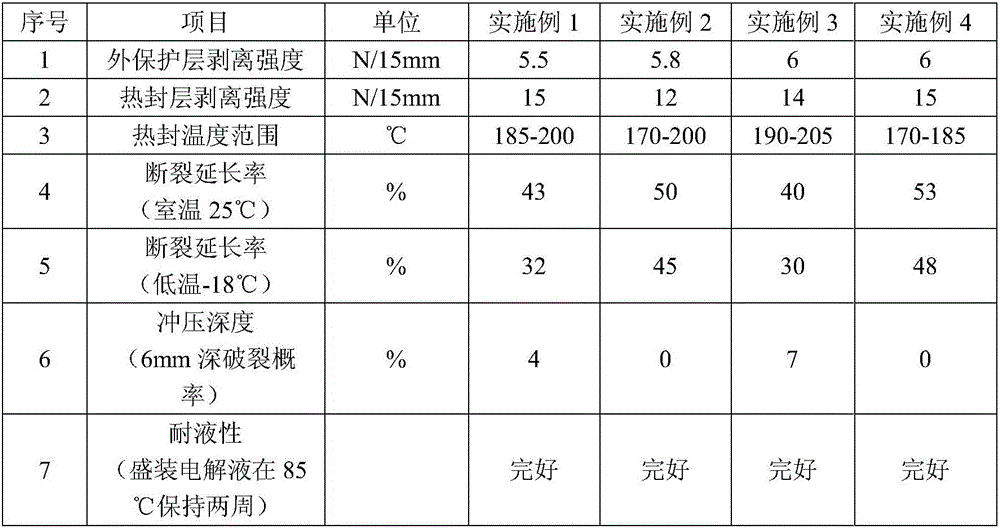

[0040] refer to figure 1 , the aluminum-plastic composite film with excellent heat-sealing performance and low-temperature toughness of this embodiment sequentially includes a heat-sealing layer 1, a first adhesive layer 4, an aluminum foil layer 2, a second adhesive layer 5 and an outer protective layer from the inside to the outside 3; the heat-sealing layer 1 is composed of a cast polypropylene film, and the relative percentage of the β-crystal form in the cast polypropylene film to the total crystalline portion of polypropylene is 57.8%; the outer protective layer 3 is biaxially oriented polyethylene terephthalate Ethylene glycol formate layer.

[0041] The preparation method of cast polypropylene film comprises the following steps:

[0042] (1) By mass, the following raw materials are equipped: 0.02% of β crystal nucleating agent (both are calcium pimelate), 3% of nano silicon dioxide, and the balance is polypropylene (wherein 80% is polypropylene homopolymer material, ...

Embodiment 2

[0048] refer to figure 1 , the aluminum-plastic composite film with excellent heat-sealing performance and low-temperature toughness of this embodiment sequentially includes a heat-sealing layer 1, a first adhesive layer 4, an aluminum foil layer 2, a second adhesive layer 5 and an outer protective layer from the inside to the outside 3. The heat-sealing layer 1 is composed of a cast polypropylene film, and the relative percentage of the β-crystal form in the cast polypropylene film to the total crystalline portion of polypropylene is 65.7%; the outer protective layer 3 is a biaxially stretched polyamide layer.

[0049] The preparation method of cast polypropylene film comprises the following steps:

[0050] (1) By mass, the following raw materials are equipped: 0.3% of β crystal nucleating agent (both are N,N-dicyclohexyl-2,6,-naphthalene dicarboxamide), 3% of nano silicon dioxide, and the remaining The amount is polypropylene (90% of which is polypropylene homopolymer and 6...

Embodiment 3

[0056] refer to figure 1 , the aluminum-plastic composite film with excellent heat-sealing performance and low-temperature toughness of this embodiment sequentially includes a heat-sealing layer 1, a first adhesive layer 4, an aluminum foil layer 2, a second adhesive layer 5 and an outer protective layer from the inside to the outside 3; the heat-sealing layer 1 is made of a cast polypropylene film, and the relative percentage of the β-crystal form in the cast polypropylene film to the total crystalline portion of polypropylene is 40.7%; the outer protective layer 3 is biaxially oriented polyethylene terephthalate Ethylene glycol formate layer.

[0057] The preparation method of cast polypropylene film comprises the following steps:

[0058] (1) By mass, the following raw materials are equipped: 0.5% of β crystal nucleating agent (wherein 0.3% is γ-quinacridone, and 0.2% is dihydroquinacridone), 3% of nano silicon dioxide, and the remaining The amount is polypropylene (70% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com