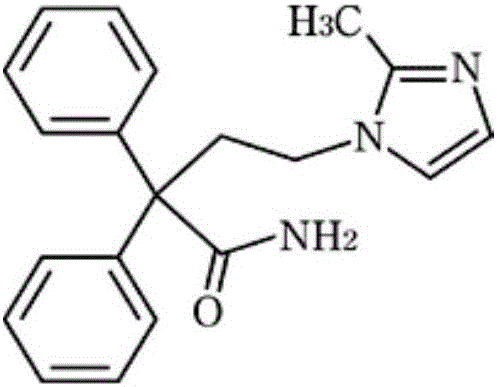

Imidafenacin tablet preparation method

A technology of midanaxin and tablets, which is applied in the field of pharmaceutical preparations, can solve problems such as uniformity, and achieve the effects of improving efficiency, improving practicability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Midanaxin sheet preparation (in every 1000 sheet amount)

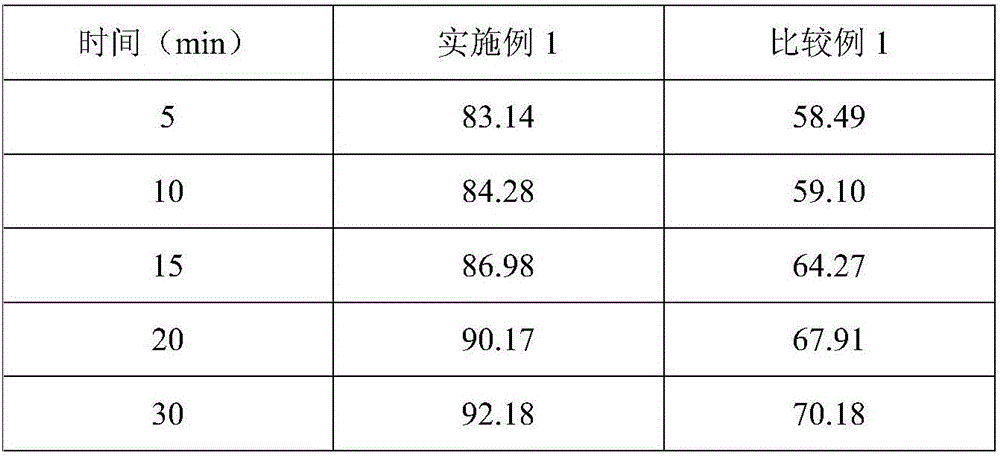

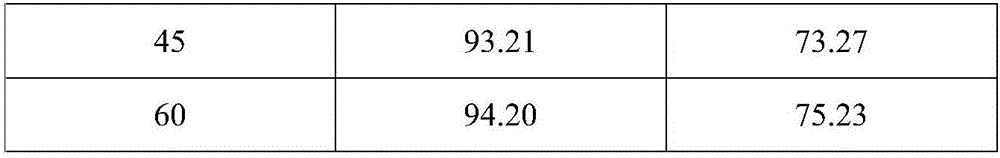

[0016] Table 1:

[0017] Name of raw material Example 1 Comparative example 1 Midana 0.1g 0.1g pregelatinized starch 58g 59.4g Microcrystalline Cellulose PH102 40g 40g Hydroxypropyl Methyl Cellulose E50 1.4g —— Povidone K30 Appropriate amount Appropriate amount Magnesium stearate 0.5g 0.5g

[0018] Embodiment 1 preparation technology:

[0019] Take the pregelatinized starch, microcrystalline cellulose PH102 and povidone K30 of the prescription amount and mix them uniformly at room temperature for 10 minutes, and set aside; Disperse and dissolve in an appropriate amount of absolute ethanol, and set aside; Spray the above-mentioned absolute ethanol containing the main drug on the above-mentioned excipients, then add the prescribed amount of magnesium stearate, mix evenly, and the mixing time is 10 minutes. Press the tablet and coat it. D...

Embodiment 2

[0030] Embodiment 2: preparation of midanacin sheet (in every 1000 sheet amount)

[0031] Table 4:

[0032] Name of raw material Example 2 Comparative example 2 Midana 0.1g 0.1g anhydrous lactose 58g 59.4g Microcrystalline Cellulose pH302 40g 40g Hydroxypropyl Methyl Cellulose E50 1.4g —— Povidone K30 Appropriate amount Appropriate amount Magnesium stearate 0.5g 0.5g

[0033] Embodiment 2 preparation technology:

[0034] Take the prescribed amount of anhydrous lactose, microcrystalline cellulose pH302 and povidone K30 and mix evenly at room temperature for 10 minutes, and set aside; disperse the prescribed amount of midazine and hydroxypropyl methylcellulose E50 Dissolve in an appropriate amount of absolute ethanol, and set aside; spray the above-mentioned absolute ethanol containing the main drug on the above-mentioned excipients, then add the prescribed amount of magnesium stearate, mix evenly, and the mixing time...

Embodiment 3

[0044] Embodiment 3: Midanaxin sheet preparation (in every 1000 sheet amount)

[0045] Table 7:

[0046] Name of raw material Example 3 Comparative example 3-1 Comparative example 3-2 Comparative example 3-3 Midana 0.1g 0.1g 0.1g 0.1g Microcrystalline Cellulose PH102 58g 59.4g 58g 59g Microcrystalline Cellulose PH302 40g 40g 40g 40g Hydroxypropyl Methyl Cellulose E50 1.4g —— —— —— Hydroxypropyl Methyl Cellulose E5 —— —— 1.4g —— glycerin —— —— —— 0.4g Povidone K30 Appropriate amount Appropriate amount Appropriate amount Appropriate amount Magnesium stearate 0.5g 0.5g 0.5g 0.5g

[0047] Embodiment 3 preparation technology:

[0048] Get the prescribed amount of microcrystalline cellulose PH102, microcrystalline cellulose PH302 and povidone K30 and mix them uniformly at room temperature for 10 minutes, and set aside; Disperse and dissolve E50 in an appropriate amount of absolute ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com