ZrO2/TiO2 composite photocatalyst and its preparation method and use

A catalyst and composite light technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effects of low comprehensive cost, good industrial application prospects, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

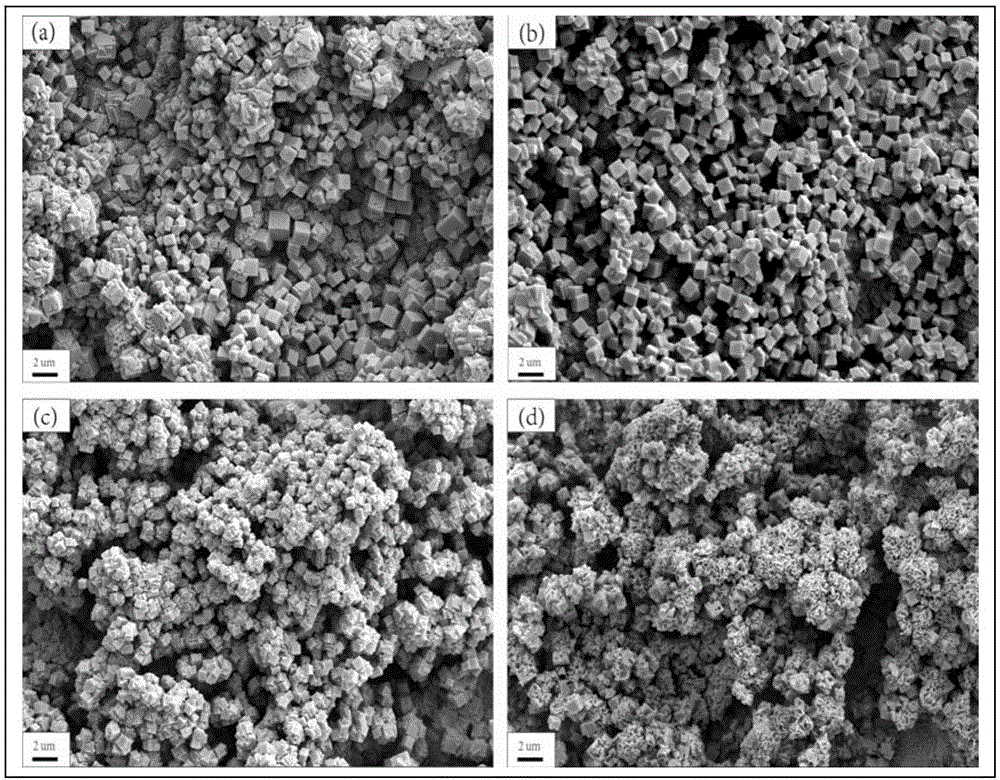

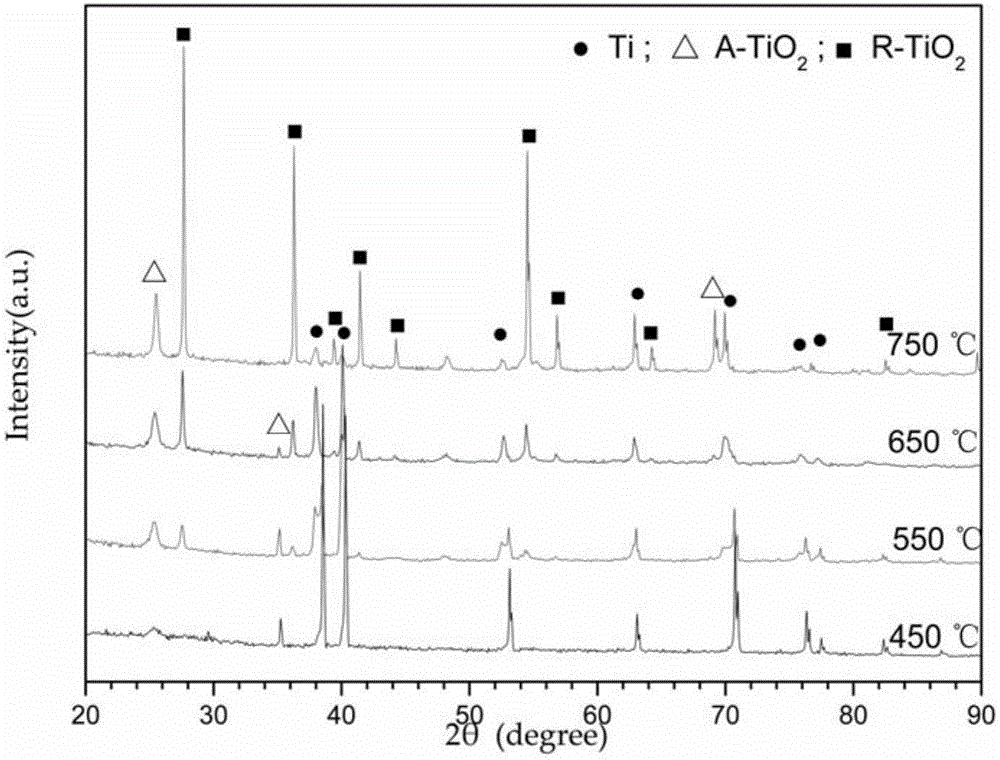

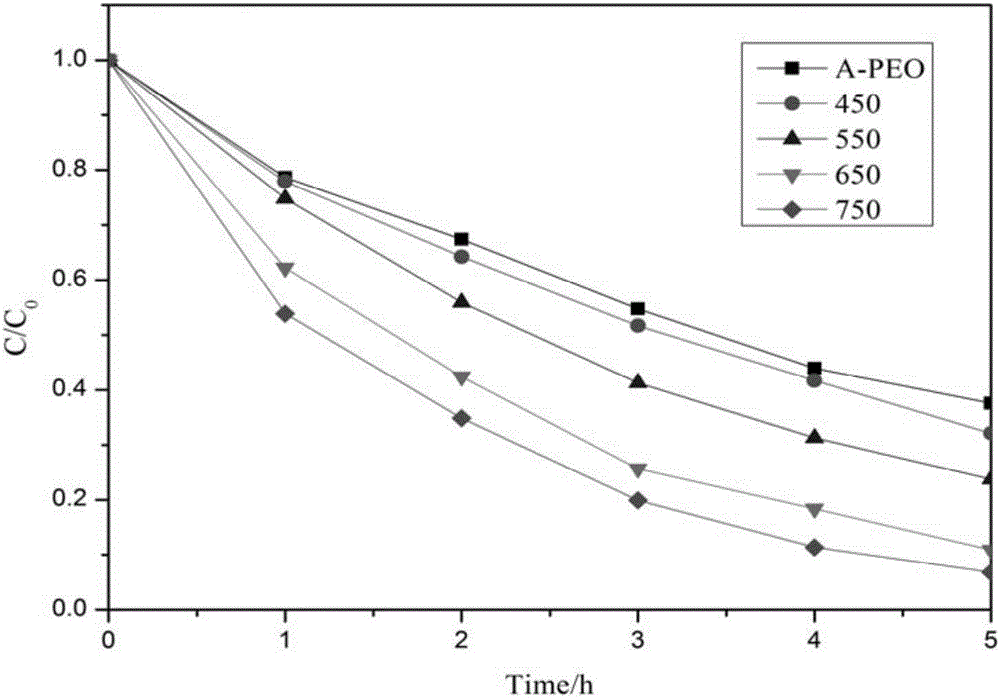

[0032] 1. Polish the Ti-6Al-4V titanium alloy through 400-mesh, 1000-mesh, and 2000-mesh sandpaper in sequence, wash with distilled water, and then blow dry.

[0033] 2. The stainless steel plate is used as the cathode, and the titanium alloy is used as the anode. The electrode distance is 30 mm. Cooling water was fed into the reactor to control the temperature of the reaction system at 30°C, and the stirring system was used to stir the electrolyte concentration and temperature to achieve a uniform distribution. The electrolyte composition is 4.0 g / L KOH (purchased from Guangzhou Donghong Chemical Factory) and 10 g / L Na 3 PO 4(purchased from Tianjin Hedong Hongyan Reagent Factory), and add 8g / L nanometer zirconia powder (Aladdin reagent), and the rest is deionized water. The plasma electrolytic oxidation voltage was 370 V for 30 min.

[0034] 3. The area of the film layer obtained in step 2 is 3cm 2 The workpiece was soaked in 2mol / L sulfuric acid solution for 24h, wash...

Embodiment 2

[0037] 1. Polish the Ti-6Al-4V titanium alloy through 400-mesh, 1000-mesh, and 2000-mesh sandpaper in sequence, wash with distilled water, and then blow dry.

[0038] 2. The stainless steel plate is used as the cathode, and the titanium alloy is used as the anode. The electrode distance is 30 mm. Cooling water was fed into the reactor to control the temperature of the reaction system at 30°C, and the stirring system was used to stir the electrolyte concentration and temperature to achieve a uniform distribution. The electrolyte composition is 4.0 g / L KOH and 10 g / L Na 3 PO 4 , and add 8g / L nano zirconium dioxide powder, and the rest is deionized water. The plasma electrolytic oxidation voltage was 370 V for 30 min.

[0039] 3. Make the film layer area obtained in step 2 3cm 2 The workpiece was soaked in 2mol / L sulfuric acid solution for 24h, washed with water, dried naturally and then calcined for 5h at a calcination temperature of 550°C to obtain ZrO 2 / TiO 2 composite...

Embodiment 3

[0042] 1. Polish the Ti-6Al-4V titanium alloy through 400-mesh, 1000-mesh, and 2000-mesh sandpaper in sequence, wash with distilled water, and then blow dry.

[0043] 2. The stainless steel plate is used as the cathode, and the titanium alloy is used as the anode. The electrode distance is 30 mm. Cooling water was fed into the reactor to control the temperature of the reaction system at 30°C, and the stirring system was used to stir the electrolyte concentration and temperature to achieve a uniform distribution. The electrolyte composition is 4.0 g / L KOH and 10 g / L Na 3 PO 4 , and add 8g / L nano zirconium dioxide powder, and the rest is deionized water. The plasma electrolytic oxidation voltage was 370 V for 30 min.

[0044] 3. The area of the film layer obtained in step 2 is 3cm 2 The workpiece was soaked in 2mol / L sulfuric acid solution for 24h, washed with water, dried naturally and then calcined for 5h at a calcination temperature of 650°C to obtain ZrO 2 / TiO 2 co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com