Synthetic method for mesoporous foamed silica-loaded precious metal nanometer catalyst

A technology of nano-catalyst and synthesis method, which is applied in the field of synthesis of mesoporous foamed silica-supported noble metal nano-catalyst, which can solve the problems of poor catalyst stability, aggregation and growth, etc., and achieve good stability, simple operation and low pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

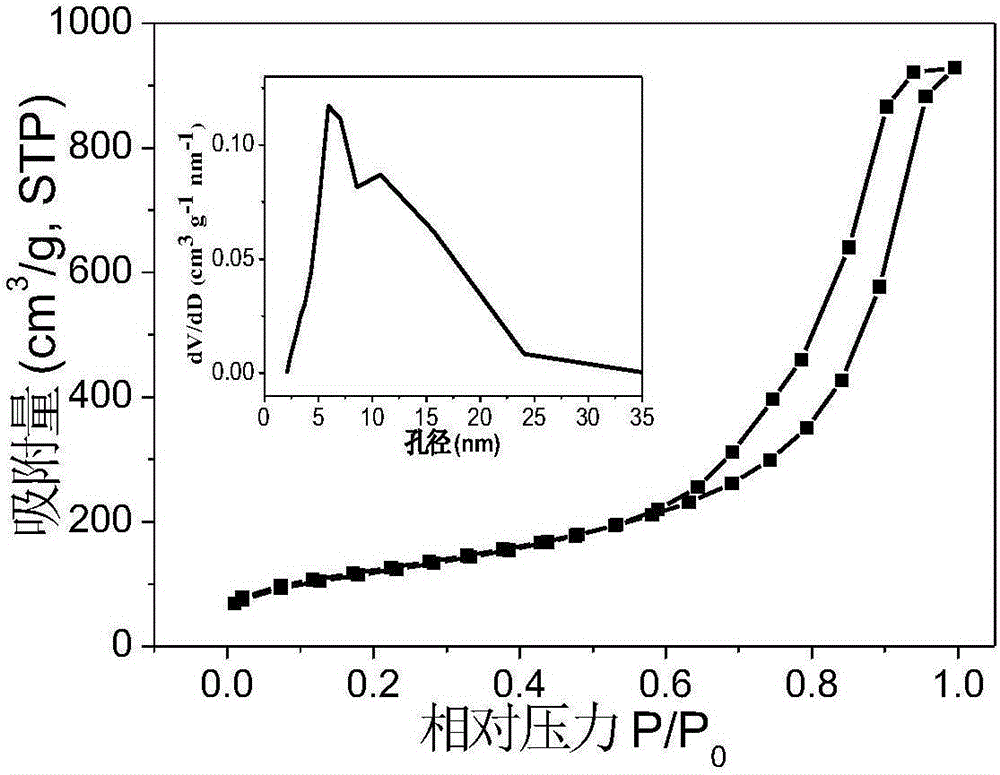

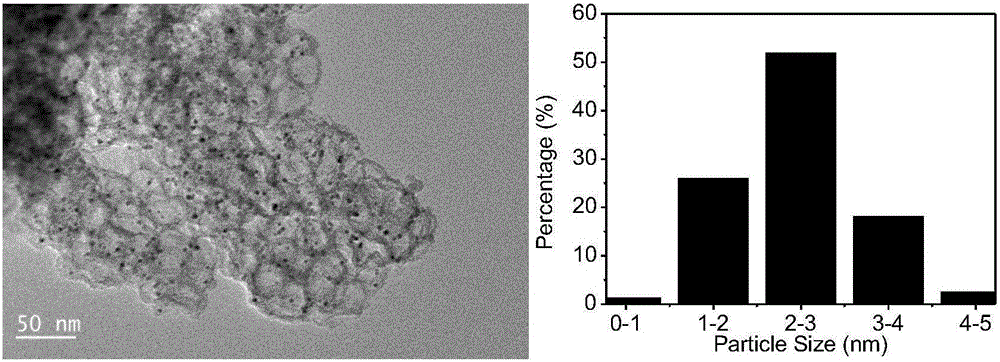

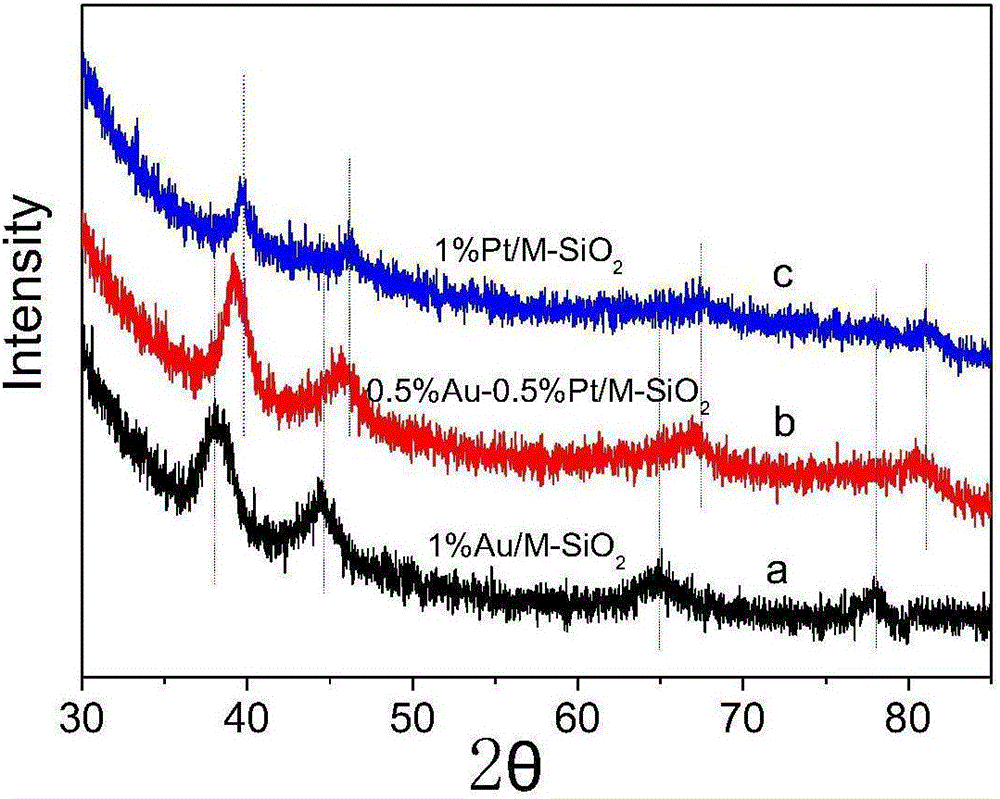

[0022] Example 1: Dissolve 2g of P123 in 32ml of deionized water and 5ml of concentrated hydrochloric acid solution, and stir at room temperature for 2 hours until clear. Slowly drop 2 g of 1,3,5-TMB into the solution and stir for 2 hours until the solution is clear. Then, 4.6 g of TEOS and 0.3 g of 3-mercaptopropyltrimethoxysilane (MPTMS) were added dropwise and stirred evenly. Then add 4ml of 0.02mol / L tetrachloroauric acid solution, and stir at 38°C for 24 hours. The resulting mixture was transferred to a crystallization kettle and placed in an oven at 100°C for crystallization for 24 hours. After the reaction, it was taken out, cooled, filtered with suction, washed, and dried to obtain a powdery solid. The white powdery solid was calcined at 550° C. for 6 hours in an air atmosphere. The reduction of the catalyst is to reduce at 500°C for 1h under a hydrogen atmosphere to obtain Au / M-SiO 2 catalyst. Depend on figure 1 N in 2 The adsorption-desorption isotherm and pore...

Embodiment 2

[0023] Example 2: Dissolve 2g of P123 in 32ml of deionized water and 5ml of concentrated hydrochloric acid solution, and stir at room temperature for 2 hours until clear. Slowly drop 2.8g of 1,3,5-TMB into the solution, and stir for 2 hours until the solution is clear. Then 4.6 g of TEOS and 0.32 g of 3-mercaptopropyltrimethoxysilane (MPTMS) were added dropwise and stirred evenly. Then, 2 ml of 0.02 mol / L tetrachloroauric acid solution and 2 ml of 0.02 mol / L chloroplatinic acid solution were added successively, and stirred at 38° C. for 24 hours. The resulting mixture was transferred to a crystallization kettle and placed in an oven at 110°C for crystallization for 24 hours. After the reaction, it was taken out, cooled, filtered with suction, washed, and dried to obtain a powdery solid. The white powdery solid was calcined at 500° C. for 8 hours in an air atmosphere. The reduction of the catalyst is to reduce at 500°C for 2h under a hydrogen atmosphere to obtain Au-Pt / M-SiO ...

Embodiment 3

[0024] Example 3: Dissolve 2g of P123 in 32ml of deionized water and 5ml of concentrated hydrochloric acid solution, and stir at room temperature for 2 hours until clear. Slowly drop 2.5g of 1,3,5-TMB into the solution and stir for 2 hours until the solution is clear. Then 4.6 g of TEOS and 0.35 g of 3-mercaptopropyltrimethoxysilane (MPTMS) were added dropwise and stirred evenly. Then 2ml of 0.02mol / L tetrachloroauric acid solution and 7ml of 0.01mol / L palladium chloride solution were added successively, and stirred at 40°C for 24 hours. The resulting mixture was transferred to a crystallization kettle and placed in an oven at 120°C for crystallization for 24 hours. After the reaction, it was taken out, cooled, filtered with suction, washed, and dried to obtain a powdery solid. The white powdery solid was calcined at 550° C. for 6 hours in an air atmosphere. The reduction of the catalyst is carried out at 500°C for 2 hours under a hydrogen atmosphere to obtain Au-Pd / M-SiO 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com