Preparation method and application of black phosphorus quantum dots with high yield

A quantum dot, high-yield technology, applied in the field of nano-material preparation, can solve the problems of low yield, limited application, time-consuming and energy-consuming, etc., and achieve high-yield preparation and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] (1) Weigh 30 mg of black phosphorus crystals in an anhydrous and oxygen-free glove box (water and oxygen <0.1 ppm), grind for 30 min, disperse into 35 ml of N-methylpyrrolidone solvent, seal and take out.

[0022] (2) Using the liquid phase exfoliation method, put the above dispersion into a probe-type ultrasonic instrument (600W) for ultrasonic dispersion for 2 hours, and the entire ultrasonic process is completed under ice bath conditions. Stand still for 2 hours after the completion of ultrasound, take the upper liquid and centrifuge (2000rpm, 30min).

[0023] (3) Take the supernatant and transfer it to a 50ml reaction kettle, put it in a high-temperature furnace, and carry out solvothermal reaction (140°C, 8h). That is, black phosphorus quantum dots with uniform size and diameter of several nanometers are obtained.

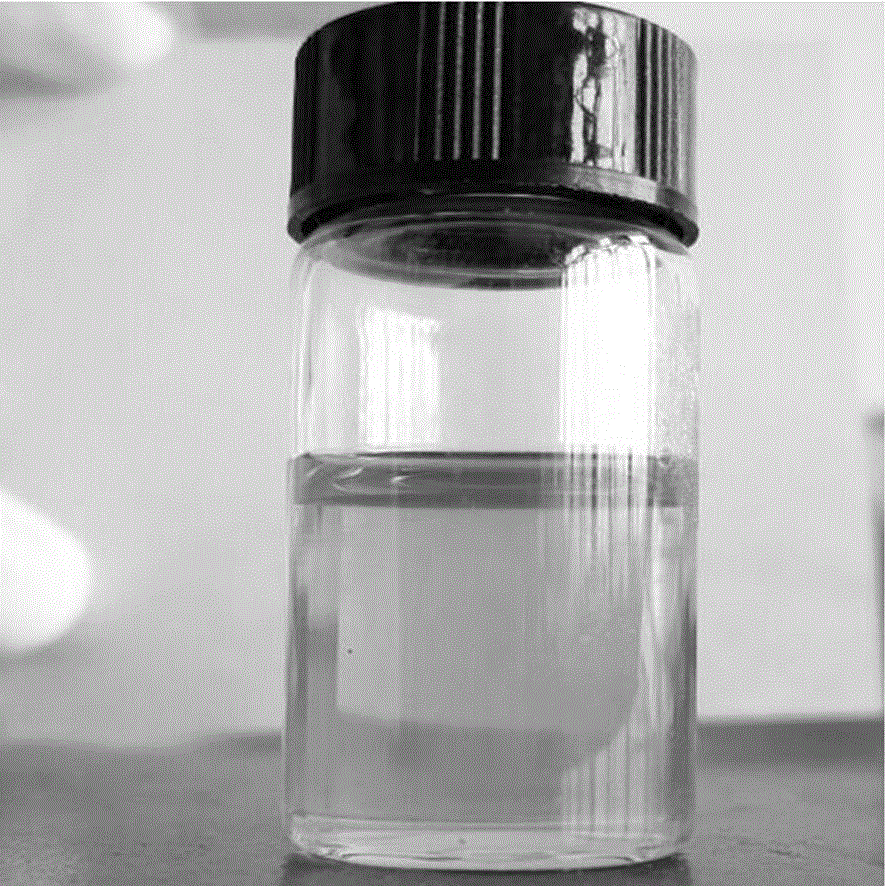

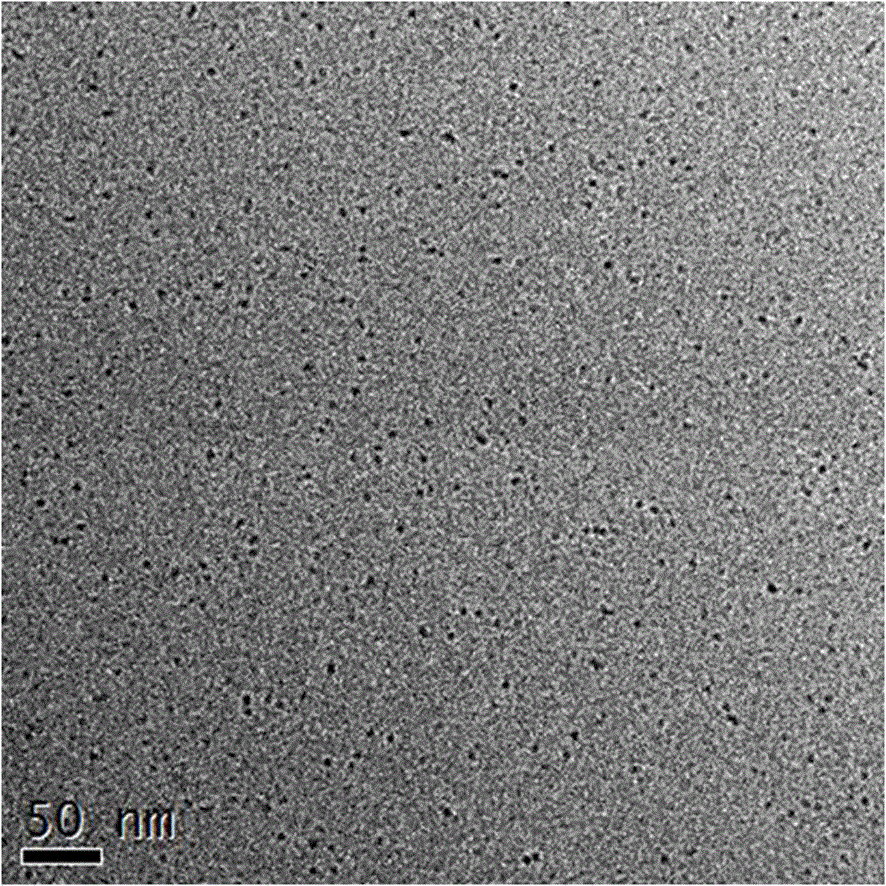

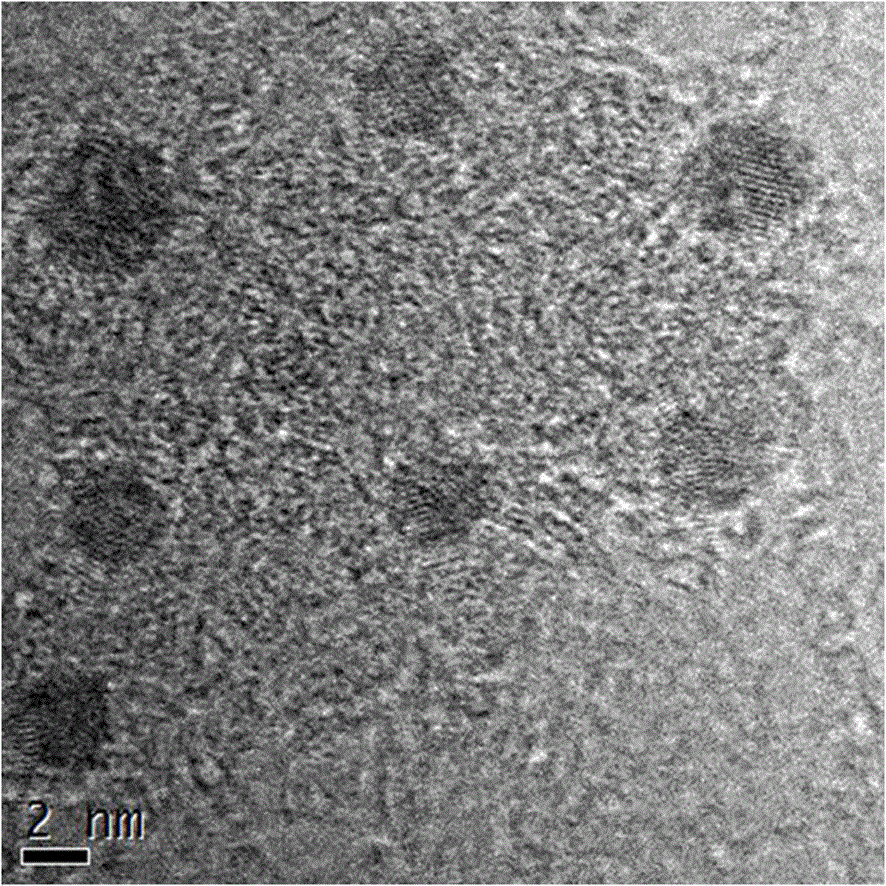

[0024] The product obtained in Example 1 is characterized, and the results are shown in Figures 1 to 3. in, figure 1 Digital photograph of the prep...

example 2

[0026] (1) Weigh 10 mg of black phosphorus crystals in an anhydrous and oxygen-free glove box (water and oxygen < 0.1 ppm), grind for 40 min, disperse into 20 ml of N-methylpyrrolidone solvent, seal and take out.

[0027] (2) Using the liquid phase exfoliation method, put the above dispersion into a probe-type ultrasonic instrument (650W) for ultrasonic dispersion for 1 hour, and the entire ultrasonic process was completed under ice bath conditions. Stand still for 1 hour after the completion of ultrasound, take the upper liquid and centrifuge (1500rpm, 20min).

[0028] (3) Take the supernatant and transfer it to a 50ml reaction kettle, put it into a high-temperature furnace, and carry out solvothermal reaction (120°C, 6h). That is, black phosphorus quantum dots with uniform size and diameter of several nanometers are obtained.

example 3

[0030] (1) Weigh 50 mg of black phosphorus crystals in an anhydrous and oxygen-free glove box (water and oxygen <0.1 ppm), grind for 60 min, disperse into 100 ml of N-methylpyrrolidone solvent, seal and take out.

[0031] (2) Using the liquid phase exfoliation method, put the above dispersion liquid into a high-probe ultrasonic instrument (900W) for ultrasonic dispersion for 3 hours, and the entire ultrasonic process is completed under ice bath conditions. Stand still for 2 hours after the completion of ultrasound, take the upper liquid and centrifuge (1800rpm, 40min).

[0032] (3) Take the supernatant and transfer it to a 50ml reaction kettle, put it in a high-temperature furnace, and carry out solvothermal reaction (130°C, 10h). That is, black phosphorus quantum dots with uniform size and diameter of several nanometers are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com