Preparation method for amino-functionalized macroporous styrene resin with large specific surface

A technology of amino functionalization and macroporous styrene, applied in the field of material science, can solve the problems of macromolecular catalytic pore size limitation, lack of pore structure, and complicated steps, and achieve improved catalytic performance and regeneration ability, simple preparation, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

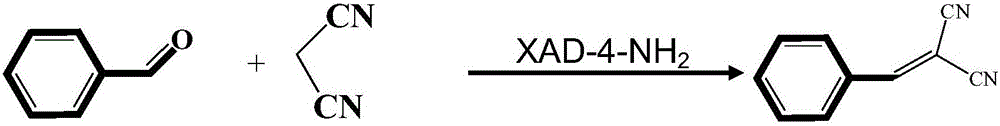

Method used

Image

Examples

Embodiment 1

[0017] Under room temperature, 1.0 gram of XAD-4 macroporous resin (purchased by Sigma-Aldrich, white spherical particles) was dispersed in 30 gram of concentrated nitric acid solution and 60 gram of concentrated sulfuric acid solution, the mass fraction of concentrated nitric acid was 35%, concentrated The mass fraction of sulfuric acid was 98%, and it was nitrated at 10°C for 72 hours, then the product was dispersed in a large amount of deionized water, washed with suction to neutrality and then dried. The obtained product had a mass of 1.5 grams.

[0018] The dried product (1.5 g) was dispersed in a mixed aqueous solution of 40 g of concentrated hydrochloric acid (37.5% by mass fraction) and 5 g of tin protochloride at room temperature for 72 hours with stirring and reduction, and the product was washed with a large amount of water and dried, and the resulting product quality was 1.46 g .

[0019] Disperse 1.46 g of the above product in 30 ml of n-butylamine and stir at roo...

Embodiment 2

[0021] Get 1.0 grams of XAD-4 macroporous resin and disperse in 5 grams of concentrated nitric acid solution (mass fraction is 35%) and 15 grams of concentrated sulfuric acid solution (mass fraction is 98%), nitrate under the condition of 0 ℃ for 12 hours, then the product is dispersed In a large amount of deionized water, filter and wash to neutrality and then dry, the obtained product has a mass of 1.53 g. The dried product was then dispersed in a mixed aqueous solution of 10 grams of concentrated hydrochloric acid (37.5% by mass) and 1 gram of stannous chloride and reduced for 12 hours at room temperature. The product was washed with a large amount of water and then dried. The resulting product had a quality of 1.54 grams. Then be dispersed in 30 milliliters of n-butylamines and activate 2 times (operating procedure is the same as embodiment 1), dry after suction filtration and obtain the specific surface area of product product is 800m 2 / g, the pore volume reaches 1.13c...

Embodiment 3

[0023] Get 1.0 gram of XAD-4 macroporous resin and be dispersed in 15 gram nitric acid solution (mass fraction is 35%) and 40 gram sulfuric acid solution (mass fraction is 98%), nitrate under the condition of 5 ℃ for 50 hours, then product is dispersed in a large amount of In deionized water, suction-filtered and washed until neutral, and then dried, the obtained product had a mass of 1.61 g. The dried product was then dispersed in a mixed aqueous solution of 20 grams of concentrated hydrochloric acid (37.5 percent by mass) and 2.5 grams of stannous chloride and reduced for 56 hours at room temperature. The product was washed with a large amount of water and then dried. The resulting product had a quality of 1.52 grams. Then disperse in 30 milliliters of n-pentylamine and activate twice, dry to obtain the specific surface area of the product product after suction filtration is 710m 2 / g, the pore volume reaches 1.0cm 3 / g, the pore diameter is 20.2 nanometers, and the amino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com