Water-borne epoxy zinc-rich lacquer and painting method thereof

A water-based epoxy zinc-rich, coating method technology, applied in epoxy resin coatings, devices for coating liquid on surfaces, coatings, etc., can solve the problem of limiting the application of water-based epoxy zinc-rich paint, environmental and human health damage , No major progress has been made, etc., to prevent precipitation, improve adhesion, and reduce the volatilization of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

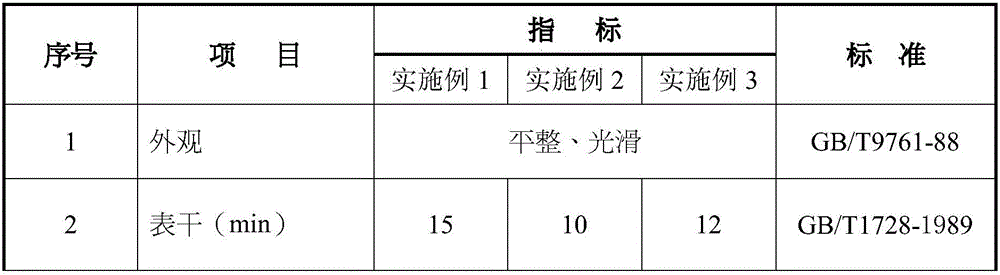

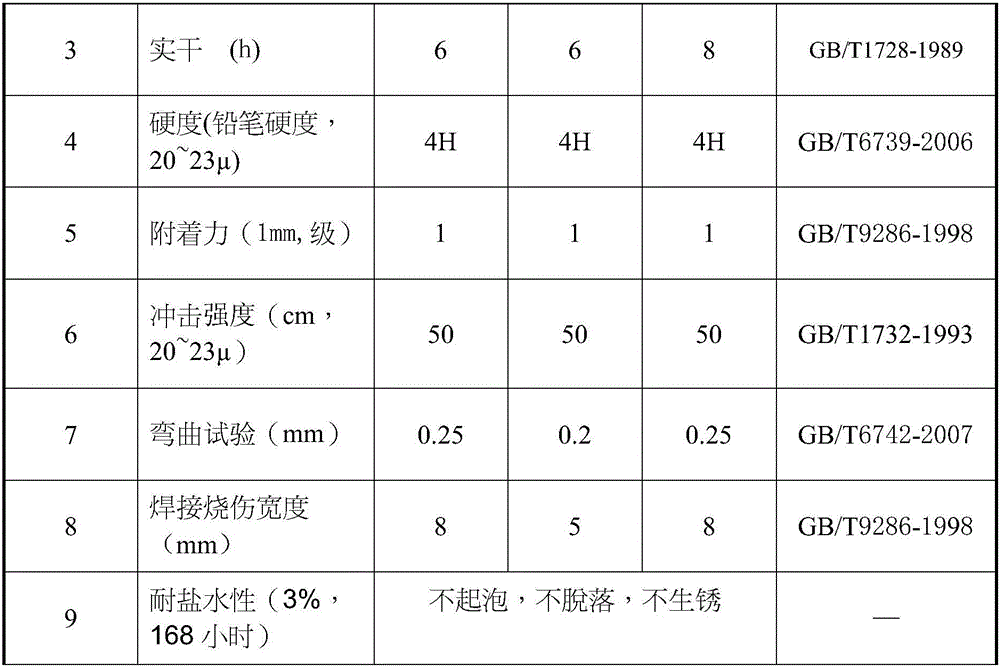

Embodiment 1

[0026] A kind of water-based epoxy zinc-rich paint of the present embodiment mainly includes the raw materials of following weight ratio: 8 parts of water-based epoxy resin, 55 parts of zinc powder, 0.5 part of bentonite, 8.5 parts of neutralizing agent, 3 parts of leveling agent, 25 parts of polyamide curing agent.

[0027] The coating method of a kind of water-based epoxy zinc-rich paint of the present embodiment is specifically that the surface of the steel structure is derusted by a grinder or sandblasting to make it reach the Swedish derusting standard Sa2.5 grade; to ensure that the steel structure When the temperature is higher than 5°C, the water-based epoxy zinc-rich paint is applied by spraying, the film thickness is 60μm, and the spraying amount per square meter of the surface of the steel structure is 0.2kg; 3 coats, each The interval between spraying is 24 hours; among them, during the painting process, the water-based epoxy zinc-rich paint is stirred after a peri...

Embodiment 2

[0029] A kind of water-based epoxy zinc-rich paint of the present embodiment mainly includes the raw materials of following weight ratio: 10 parts of water-based epoxy resin, 61.5 parts of zinc powder, 0.5 part of bentonite, 5 parts of neutralizing agent, 3 parts of leveling agent, 20 parts of polyamide curing agent.

[0030] The coating method of a kind of water-based epoxy zinc-rich paint of the present embodiment is specifically that the surface of the steel structure is derusted by a grinder or sandblasting to make it reach the Swedish derusting standard Sa2.5 grade; to ensure that the steel structure When the temperature is higher than 5°C, the water-based epoxy zinc-rich paint is applied by spraying, the film thickness is 80 μm, and the spraying amount per square meter of the surface of the steel structure is 0.2kg; 2 coats, 2 The interval between spraying is 24 hours; among them, during the painting process, the water-based epoxy zinc-rich paint is stirred after a perio...

Embodiment 3

[0032] A kind of water-based epoxy zinc-rich paint of the present embodiment mainly includes the raw materials of following weight ratio: 15 parts of water-based epoxy resin, 60 parts of zinc powder, 0.5 part of bentonite, 5.5 parts of neutralizing agent, 3 parts of leveling agent, 16 parts of polyamide curing agent.

[0033] The coating method of a kind of water-based epoxy zinc-rich paint of the present embodiment is specifically that the surface of the steel structure is derusted by a grinder or sandblasting to make it reach the Swedish derusting standard Sa2.5 grade; to ensure that the steel structure When the temperature is higher than 5°C, the water-based epoxy zinc-rich paint is applied by spraying, the film thickness is 80 μm, and the spraying amount per square meter of the surface of the steel structure is 0.2kg; 2 coats, 2 The interval between spraying is 48 hours; among them, during the painting process, the water-based epoxy zinc-rich paint is stirred after a perio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com