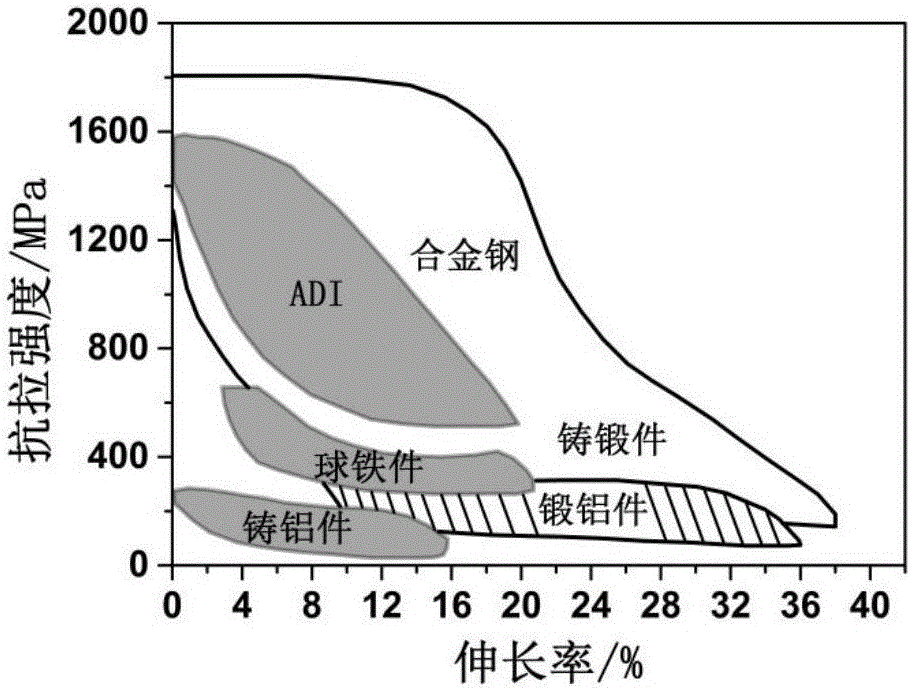

Austempering heat treatment method of high bending property austempered ductile cast iron (ADI)

A heat treatment method and isothermal quenching technology, which is applied in the field of heat treatment, can solve the problems of salt bath slow cooling ability, harm to human body, difficult to remove dross, etc., and achieve the effects of reducing heat treatment cost, delaying internal stress generation, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

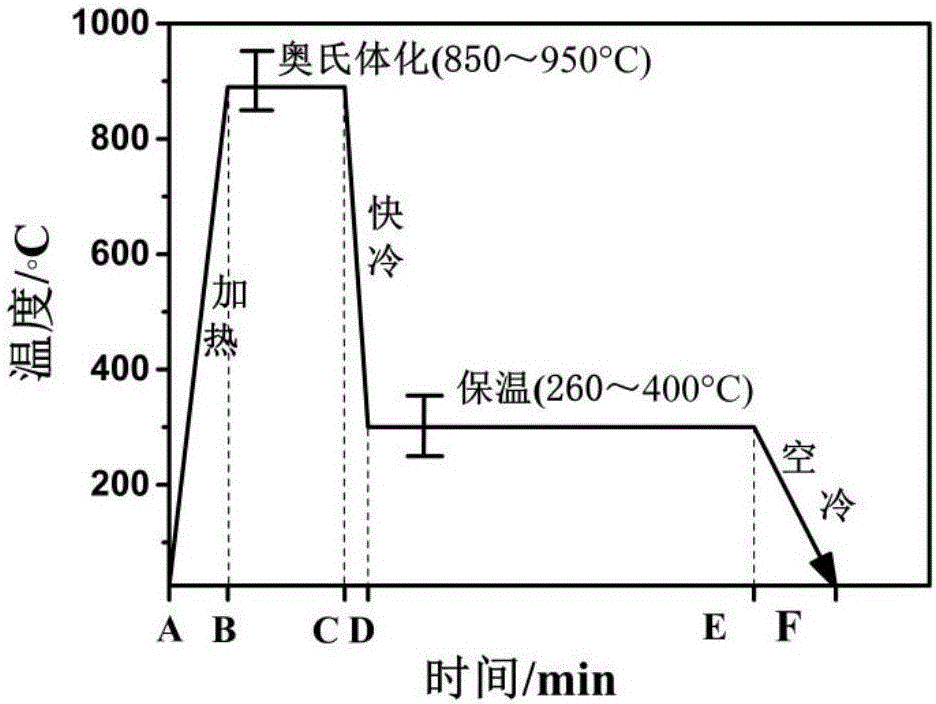

[0033] The heat treatment process of the Aube ductile iron of the present invention is as follows:

[0034] Step 1: Prepare two ordinary resistance heating furnaces, one of which is heated to 860-900°C, while the other is heated to 200-300°C. Wait for the temperature to stabilize before proceeding to the following steps.

[0035] Step 2: Bind the workpiece with thin iron wire, hang the wire on the slender iron hook, quickly push it into the heating furnace with a temperature of 860-900°C, and make the workpiece close to the thermocouple. The holding time is calculated according to the effective thickness of the workpiece, holding time / min=effective thickness mm×1-2min. After the workpiece is sent into the heating furnace, wait for the temperature to stabilize at 860-900°C and start counting the holding time.

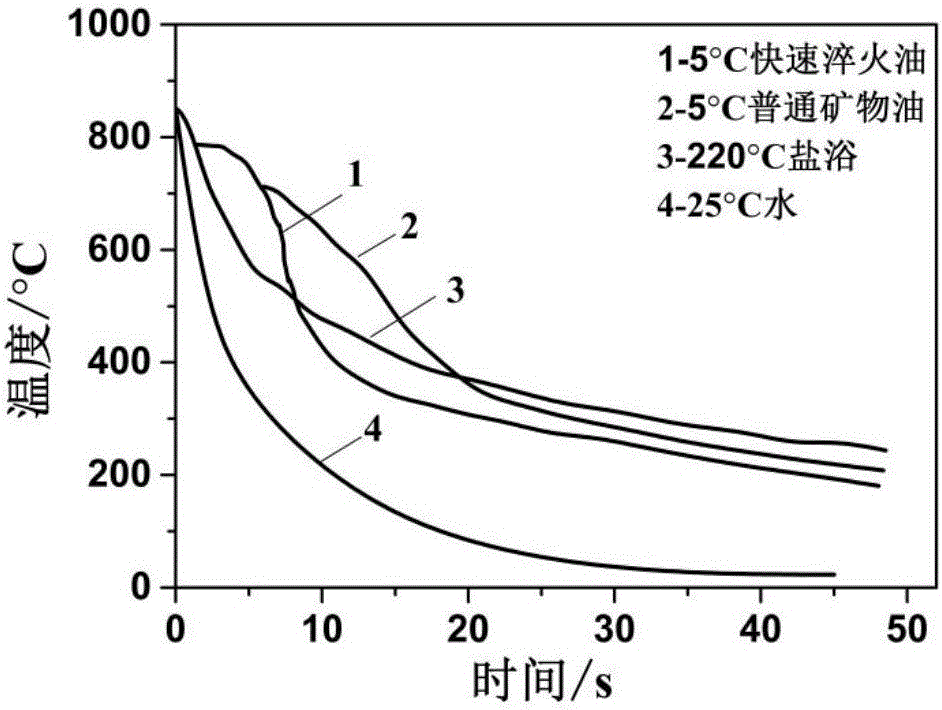

[0036] Step 3: After the heat treatment, take out the workpiece quickly, and quickly quench it in the self-made quenching water-based suspension medium at room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending fatigue strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com