Power grid fault ultrasonic testing device and method

A detection device and a technology for power grid faults, which are applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problems of increasing labor intensity of staff, affecting power supply reliability, and faults Frequent and complex problems, to achieve the effect of friendly operation interface, light weight and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

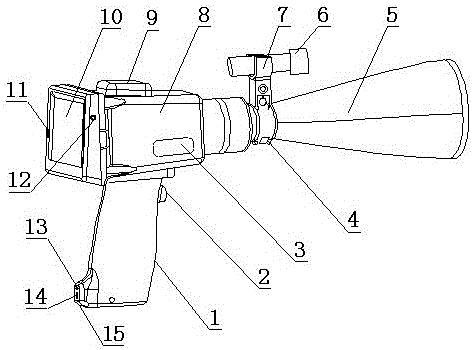

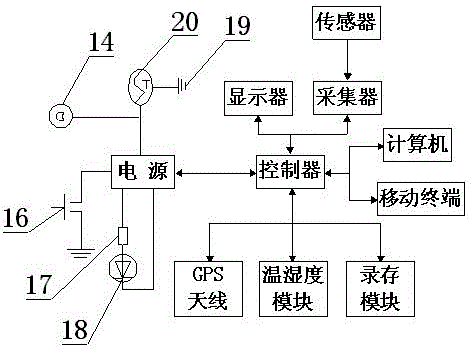

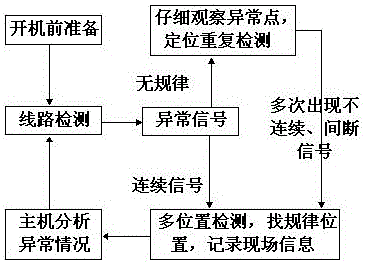

[0022] Such as figure 1 , figure 2 and image 3 As shown, a power grid fault ultrasonic detection device and detection method thereof, it includes a nacelle 8, the bottom of the nacelle 8 is connected with a handle 1, the front end of the handle 1 is provided with an intelligent switch 2, the handle 1 is provided with a charging hole 14 and a charging indicator light 13, the handle 1 is provided with an anti-drop device 15, and the front part of the cabin 8 is provided with a signal converter 4, and the signal converter 4 is connected to Round table receiver 5, the top of described round table receiver 5 is equipped with sight bracket 7, and described sight bracket 7 is equipped with laser sight 6, and the top of described nacelle 8 is equipped with GPS antenna 9, described The back of the cabin 8 is connected with a display 10, the cabin 8 is provided with a USB interface 11 and an earphone jack 12, the display 10 is connected with a controller, and the controller is conne...

Embodiment 2

[0030] Such as figure 1 , figure 2 and image 3As shown, a power grid fault ultrasonic detection device and detection method thereof, it includes a nacelle 8, the bottom of the nacelle 8 is connected with a handle 1, the front end of the handle 1 is provided with an intelligent switch 2, the handle 1 is provided with a charging hole 14 and a charging indicator light 13, the handle 1 is provided with an anti-drop device 15, and the front part of the cabin 8 is provided with a signal converter 4, and the signal converter 4 is connected to Round table receiver 5, the top of described round table receiver 5 is equipped with sight bracket 7, and described sight bracket 7 is equipped with laser sight 6, and the top of described nacelle 8 is equipped with GPS antenna 9, described The back of the cabin 8 is connected with a display 10, the cabin 8 is provided with a USB interface 11 and an earphone jack 12, the display 10 is connected with a controller, and the controller is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com