Improved nicotinamide fusion spraying granulation tower and operation method thereof

A spray granulation tower, nicotinamide technology, applied in the field of machinery, can solve the problems of uneven and consistent specifications of formed particles, difficult to control the granulation process, flying dust, etc., to optimize the consistency of granulation size and enhance the ability to capture powder. ability, the effect of enhancing the thrust of the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

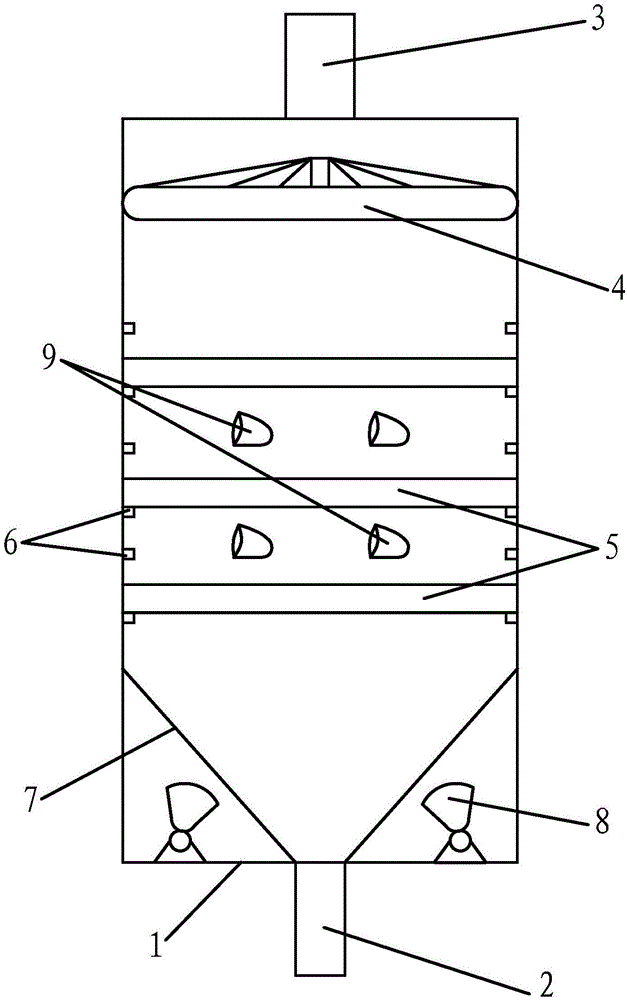

[0024] like figure 1 As shown, the improved nicotinamide melt spray granulation tower includes a cylindrical tower body 1 and a console, the top of the tower body 1 is provided with an exhaust pipe 3, the bottom of the tower body 1 is provided with an air inlet pipe 2, and the tower body 1 is divided from bottom to top into a wind area, a suspension area and a spray area; the spray area is provided with an atomizing nozzle assembly 4, and the atomizing nozzle assembly 4 includes a number of ring tubes set in order from small to large. The nozzles are evenly distributed on the bottom surface, and the shaft assembly is arranged in the center of several coil pipes. Drive connection; several suspension boards 5 are arranged u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com