Dielectrophoresis-based chip for separation of deformable microparticles

A particle separation and dielectrophoresis technology, used in laboratory containers, laboratory utensils, fluid controllers, etc., can solve the problems of sample particle destructiveness, cumbersome steps, and experimental irreversibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

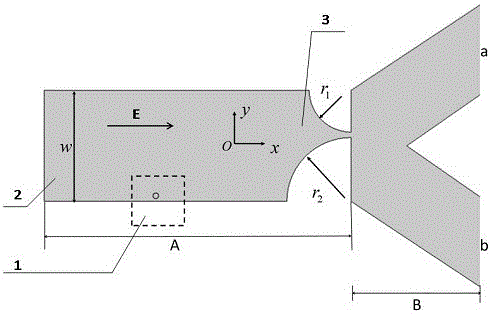

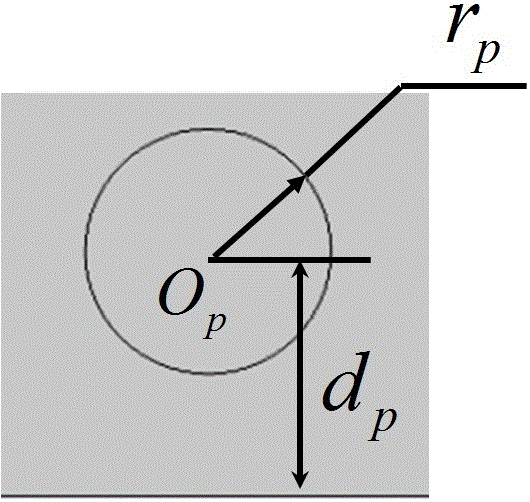

[0034] A microfluidic chip based on dielectrophoresis for the separation of deformable particles, using PDMS as the material, and making an SU8 mold through photolithography, development and other process steps; then coating the PDMS material mixed with the curing agent on the mold, and after After heating and curing, the PDMS negative mold is obtained by demoulding; then the PDMS material mixed with the curing agent is coated on the PC sheet, and then heated and cured, and then demoulded to obtain the PDMS flat plate; the microstructure obtained by bonding the PDMS negative mold and the flat plate is the obtained The microfluidic chip structure described above.

[0035] In order to better separate the particles, the tangential modulus is used in the present invention as a distinguishing mark for different particles. The tangential modulus G is a material property and has nothing to do with the stress environment.

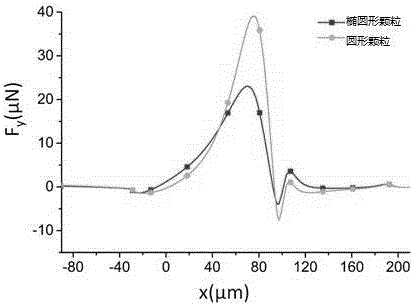

[0036] Under the applied electric field, the DEP forces of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com