Stainless steel water bath dedusting and desulfurizing tower

A technology of water bath dedusting and desulfurization tower, which is applied in the direction of using liquid separation agent, combined device, gas treatment, etc., can solve the problems of failing to meet emission standards, ecological environment damage, etc., and achieve the effect of saving water and not polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

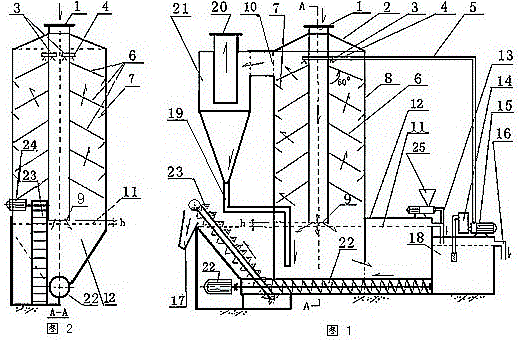

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0038] A stainless steel water bath dedusting and desulfurization tower, comprising: smoke inlet pipe 1, dust desulfurization tower top cover 2, water spray pipe 3, water spray port 4, water pump outlet pipe 5, cone-shaped sieve plate 6, ring-shaped water collecting plate 7 , dust removal and desulfurization tower shell 8, dust inlet pipe outlet 9, upper exhaust pipe 10, water level line 11, sedimentation pool 12, sedimentation pool overflow pipe 13, water pump self-priming vacuum device 14, water pump 15, clear water pool overflow pipe 16, Dust discharge outlet 17, clear water pool 18, return pipe 19, steam-water separator exhaust port 20, steam-water separator 21, low-speed mud discharge auger and motor 22, low-speed chain bucket elevator 23, chain bucket elevator motor 24, Alkali adding machine 25.

[0039] With reference to accompanying dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com