Method for electric-arc additive manufacturing of aluminum alloy multi-layer single-pass closed structural member

A kind of additive manufacturing, multi-layer single-channel technology, applied in the direction of manufacturing tools, arc welding equipment, metal processing equipment, etc., can solve the problems of low material utilization rate, prolonged production cycle, difficult mechanical processing, etc., and achieve metallurgical bonding performance Good, reduce production cost and shorten the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

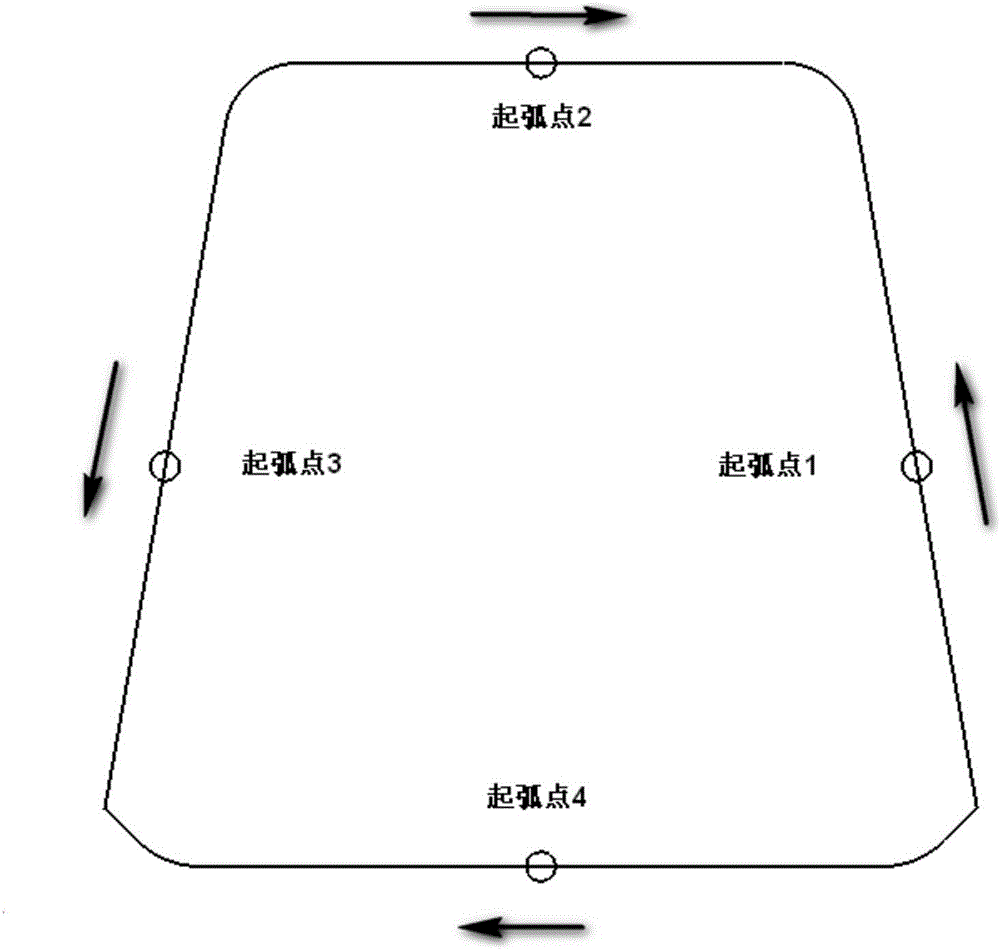

[0038] Example 1: Arc additive manufacturing of thin-walled structural parts of 5B06 aluminum alloy with straight wall and equal thickness

[0039] The specific implementation method is: welding current 95A, wire feeding speed 6m / min, stacking speed 8mm / s; welding wire diameter is ф1.2mm5B06 aluminum alloy; layer height 1.3mm, layer thickness 1.6mm, formed by stacking 200 layers of rectangular pieces; The C+P mode is selected for the three-layer bottom layer additive, and the C+P+A mode is selected for the upper additive process; the additive process uses 99.9% high-purity argon for frontal protection; the mechanical arm operates in a straight line; the arc starting point is At the midpoint of the four sides of the rectangle, every time a layer of material is added, the welding torch is raised by 1.3mm, and the arc starting point is changed to accumulate the next layer. 8mm thick aluminum alloy rectangular closed structure.

Embodiment 2

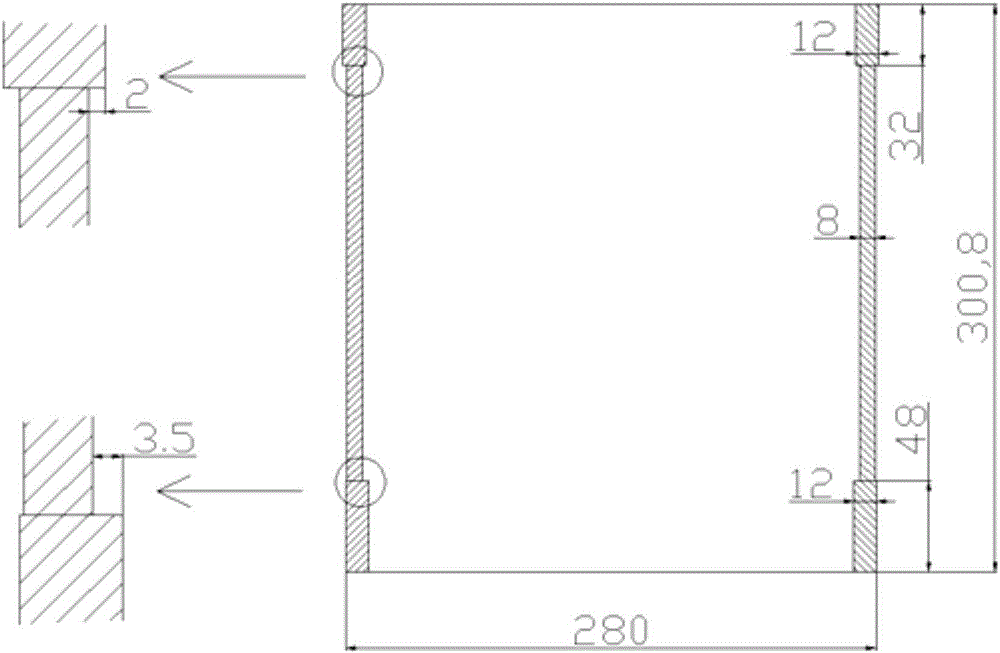

[0040] Example 2: Arc Additive Manufacturing of 5B06 Aluminum Alloy Structural Parts with Straight Walls and Unequal Thickness

[0041] This structural member is a trapezoidal straight wall structural member with three wall thicknesses in the upper, middle and lower regions and two different wall thickness transition modes. Such as figure 2 As shown, the bottom wall thickness is 12mm, the middle wall thickness is 8mm, and the upper wall thickness is 12mm.

[0042] The specific steps are:

[0043]Grind the pickled 400mm×400mm×22mm substrate flat and wipe it clean with acetone, then fix it on the workbench to ensure its level;

[0044] 99.99% high-purity argon is used for frontal protection, the gas flow rate is: 18-20L / min, and the pre-ventilation time is 5s;

[0045] Make a base buildup of the bottom three layers. The mode is C+P, the stacking method is swing stacking (frequency 7Hz, amplitude 3mm, peak dwell time 0.1s, trough dwell time 0.1s); welding current 100A, wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com