A method for improving the metallurgical strength of aluminum alloy arc-added materials

A technology of aluminum alloy and aluminum alloy components, which is applied in the field of additive manufacturing, can solve the problems of affecting the metallurgical bonding strength of parts, serious heat accumulation of stacked parts, and decline of mechanical properties of parts, so as to achieve shortened production cycle, high material utilization rate, melting deep increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Polish the surface of the pickled 20mm thick 5A06 substrate with a winch grinder to expose the bright white metal and wipe it clean with acetone or absolute ethanol.

[0043] (2) Fix the base plate on the workbench to ensure that the base plate is within the travel range of the robot.

[0044] (3) 99.999% high-purity argon is used for frontal protection, and the flow rate is 18-20L / min.

[0045] (4) Select a suitable position on the base plate as the arc starting point to lay the bottom three layers. The mode is C+P (mixed transition form of CMT transition and pulse transition), and the welding current is 20A to 50A larger than the forming current of the upper layer (that is, the additive current). Left and right, the surface of the base layer is shaped wider and flat, so that the upper layer can be completely flat on the surface of the base layer.

[0046] (5) After priming, select a suitable arc starting point. The arc starting point is the two ends of the straig...

Embodiment 2

[0056] In step (5), the additive current is 100A, the wire feeding speed is 7m / min, and the traveling speed of the welding torch is 8mm / s.

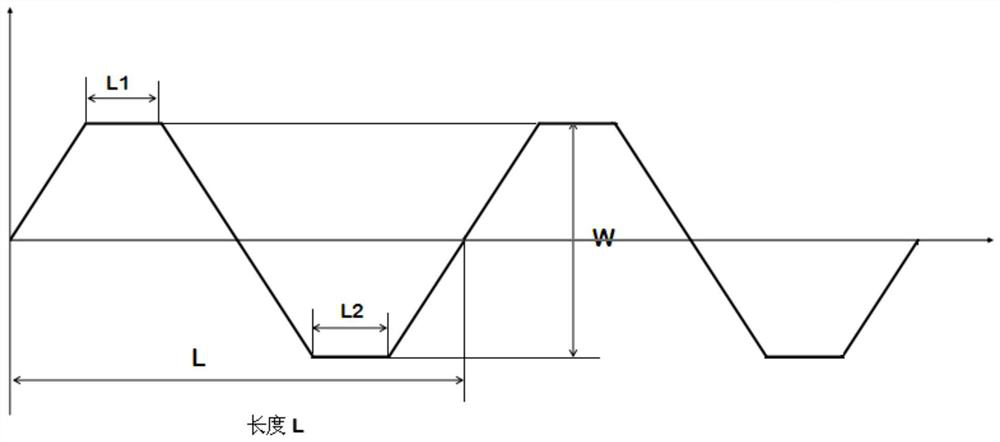

[0057] Make the welding torch swing during the additive process, see the swing mode figure 1 , the amplitude W=2mm, the time to travel forward at the maximum amplitude position is 0.2s, the time to travel forward at the maximum amplitude position is 0.2s, the travel distance of the welding torch at the wave peak L1=0.2×8=1.6mm, the welding torch The travel distance L2 at the trough is 0.2×8=1.6mm, and the length of one cycle of oscillation is L=1.6+1.6+0.2×8=4.8mm.

[0058] The single-layer cladding layer has a height of 1.2mm and a width of 10mm.

[0059] The additive mode is C+P mode (cold metal transfer process and pulse mixed transfer method). The transition mode is the same as Example 1.

[0060] The operation mode of the mechanical arm is linear reciprocating operation. Such reciprocating forming produces an aluminum alloy strai...

Embodiment 3

[0063] In step (5), the additive current is 100A, the wire feeding speed is 9m / min, and the traveling speed of the welding torch is 11mm / s.

[0064] Make the welding torch swing during the additive process, see the swing mode figure 1 , the amplitude W=5mm, the time to travel forward at the maximum amplitude position is 0.2s, the time to travel forward at the maximum amplitude position is 0.2s, the travel distance of the welding torch at the wave peak L1=0.2×11=1.1mm, the welding torch The travel distance L2 at the trough is 0.2×11=1.1mm, and the length of one cycle of oscillation is L=1.1+1.1+0.1×11=3.3mm.

[0065] The single-layer cladding layer has a height of 1.2mm and a width of 10mm.

[0066] The additive mode is C+P mode (cold metal transfer process and pulse mixed transfer method). The transition mode is the same as Example 1.

[0067] The operation mode of the mechanical arm is linear reciprocating operation. Such reciprocating forming produces an aluminum alloy s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com