A chiral nanostructure with adjustable circular dichroism and its preparation method

A circular dichroism and nanostructure technology, applied in the field of chiral nanostructure and its preparation, can solve the problems of high cost of precious metal coating materials, inaccurate measurement, broadening of spectral lines, etc., to achieve convenient long-term storage and accurate measurement signals , The effect of reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

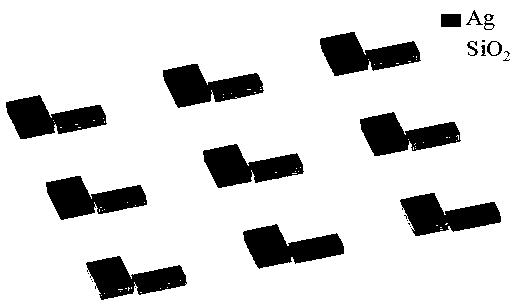

[0041] A chiral nanostructure with adjustable circular dichroism, the original structure of the structure is L-shaped, there is a gap between the long side and the short side of the L-shaped, the long side of the L-shaped is silver, and the thickness is 50nm; L The short side of the shape is a two-layer structure perpendicular to the long side. The bottom layer is silicon dioxide with a thickness of 20nm, and the upper layer is silver with a thickness of 50nm; SiO2 forms a chiral nanostructure with tunable circular dichroism.

[0042] The preparation method of any one of the above-mentioned chiral nanostructures with adjustable circular dichroism comprises the following steps:

[0043] Step 1, put the template with the polystyrene ball substrate into the vacuum coating machine, and vacuum;

[0044] Step 2, tilting the substrate by 4°, vapor-depositing silver;

[0045] Step 3, after the silver vapor deposition in the step 2 is completed, rotate the substrate by 90°, vapor dep...

Embodiment 2

[0061] A chiral nanostructure with adjustable circular dichroism, the original structure of the structure is L-shaped, there is a gap between the long side and the short side of the L-shaped, the long side of the L-shaped is silver, and the thickness is 300nm; L The short side of the shape is a two-layer structure perpendicular to the long side. The bottom layer is silicon dioxide with a thickness of 40nm, and the upper layer is silver with a thickness of 300nm; SiO2 forms a chiral nanostructure with tunable circular dichroism.

[0062] The preparation method of any one of the above-mentioned chiral nanostructures with adjustable circular dichroism comprises the following steps:

[0063] Step 1, put the template with the polystyrene ball substrate into the vacuum coating machine, and vacuum;

[0064] Step 2, tilting the substrate by 4°, vapor-depositing silver;

[0065] Step 3, after the silver vapor deposition in the step 2 is completed, rotate the substrate by 90°, vapor d...

Embodiment 3

[0072] A chiral nanostructure with adjustable circular dichroism, the original structure of the structure is L-shaped, there is a gap between the long side and the short side of the L-shaped, the long side of the L-shaped is silver, and the thickness is 100nm; L The short side of the shape is a two-layer structure perpendicular to the long side. The bottom layer is silicon dioxide with a thickness of 30nm, and the upper layer is silver with a thickness of 100nm; SiO2 forms a chiral nanostructure with tunable circular dichroism.

[0073] The preparation method of any one of the above-mentioned chiral nanostructures with adjustable circular dichroism comprises the following steps:

[0074] Step 1, put the template with the polystyrene ball substrate into the vacuum coating machine, and vacuum;

[0075] Step 2, tilting the substrate by 4°, vapor-depositing silver;

[0076] Step 3, after the silver vapor deposition in the step 2 is completed, rotate the substrate by 90°, vapor d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com