Method for comprehensive treatment of oily sludge based on hydrothermal technology

A comprehensive treatment and oily sludge technology, applied in water/sludge/sewage treatment, sludge treatment, oxidation treatment of sludge, etc., can solve problems such as environmental pollution and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

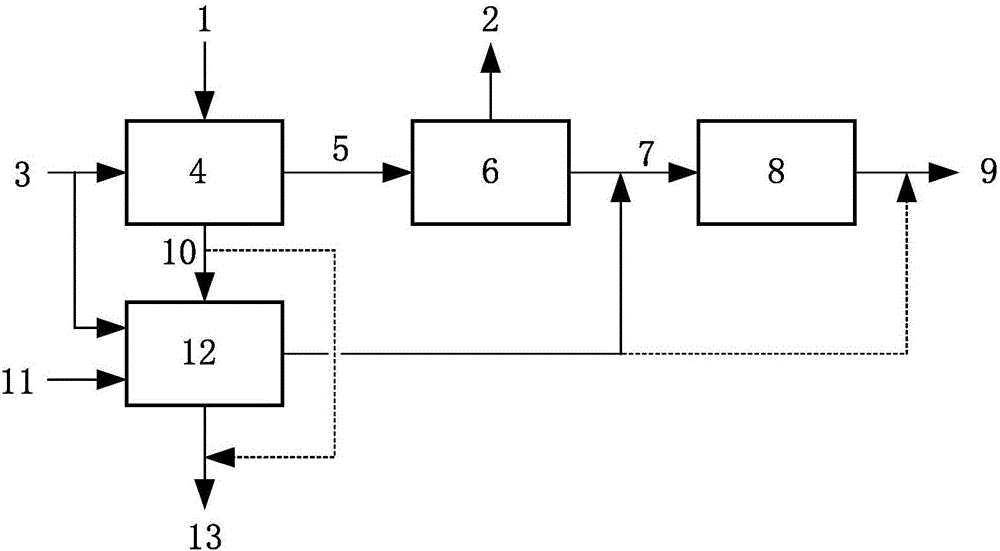

[0020] Embodiment 1 (laboratory scale)

[0021] The oily sludge produced by drilling a shale gas vertical well has a total organic content of 26.2%, of which oil organic matter is 20.6% and non-oil organic matter is 5.6%.

[0022] Using high temperature and high pressure water 3 at 330°C and 13MPa, with a flow rate of 5 liters per hour, 42.5 kg of oily sludge 1 is hydrothermally extracted in an intermittent extraction method. After about 20 minutes of extraction, the resulting waste to be treated The residue 10 is then hydrothermally oxidized 12, the oxidant 11 is air, the oxygen peroxide is 3.5, the reaction temperature is 380°C, and the reaction pressure is 22.5 MPa. After 45 minutes, the organic matter in it is completely eluted to form the final residue 13; The oil-water mixture 5 produced by the hydrothermal extraction 4 is separated into the oil phase 2 in the oil-water separator 6; the remaining liquid and the liquid produced by the hydrothermal oxidation 12 are merged ...

Embodiment 2

[0023] Embodiment 2 (laboratory scale)

[0024] The oily sludge produced by drilling a shale gas horizontal well has a total organic content of 14.1%, of which oily organic matter is 13.2% and non-oily organic matter is 0.9%.

[0025] Using 250°C, 4.5MPa high-temperature and high-pressure water 3, with a flow rate of 3 liters / hour, 42.5 kg of oily sludge 1 is hydrothermally extracted by intermittent extraction methods. After about 90 minutes of extraction, the final residue is formed. 13. The oil-water mixture 5 produced by the hydrothermal extraction 4 is separated into the oil phase 2 in the oil-water separator 6; the remaining liquid is organic waste water 7, which is oxidatively degraded by deep degradation 8 of biodegradation; after analysis, the hydrothermal extraction 2 The oil content of the residue 10 to be treated is 0.8%, the total organic matter content in the final residue 13 is 0.8%, and the effluent 9 reaches the secondary standard of "GB8978-1996 Comprehensive ...

Embodiment 3

[0026] Embodiment 3 (laboratory scale)

[0027]The oily sludge produced by drilling a shale gas vertical well has a total organic content of 28.5%, of which oil organic matter is 22.4% and non-oil organic matter is 6.1%.

[0028] Using high-temperature and high-pressure water 3 at 100°C and 20MPa, with a flow rate of 6 liters / hour, 42.5 kg of oily sludge 1 is hydrothermally extracted in a continuous extraction method. After about 120 minutes of extraction, the resulting waste to be treated The residue 10 is then hydrothermally oxidized 12, the oxidant 11 is air, the amount of oxygen peroxide is 15, the reaction temperature is 200°C, and the reaction pressure is 23MPa. After 60 minutes, the organic matter in it is completely eluted to form the final residue 13; water The oil-water mixture 5 produced by the thermal extraction 4 is separated into the oil phase 2 in the oil-water separator 6; the remaining liquid and the liquid produced by the hydrothermal oxidation 12 are merged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com