Mineral crystal fancy glaze capable of releasing negative ions and ceramic tile produced by using mineral crystal fancy glaze

A technology of mineral crystals and ceramic bricks, applied in the field of ceramic bricks, can solve the problems of deformation of the green body and the overall performance is not optimal, and achieve the effect of increasing the electrostatic voltage difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

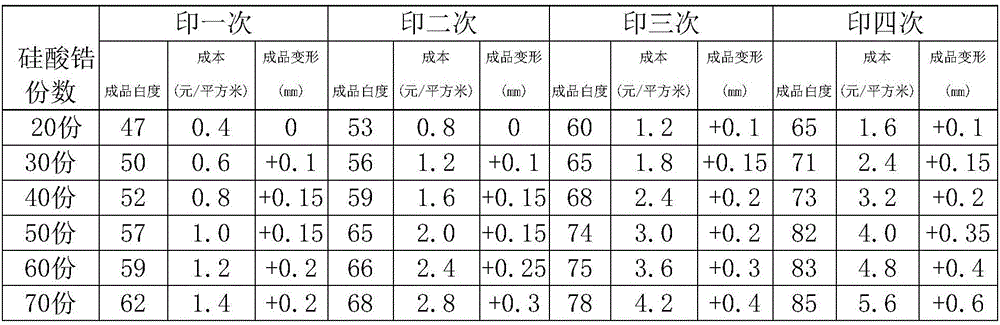

[0035] This embodiment provides a kind of mineral crystal floral glaze, which is calculated in parts by mass and includes the following components:

[0036] 100 parts of dry mineral crystals, 0-50 parts of transparent glaze, 60-80 parts of printing paste, 0.2 parts of carboxymethyl cellulose, 25-40 parts of water,

[0037] The chemical components of the dry mineral crystal particles are calculated in parts by weight of oxides, and include the following components:

[0038] SiO 2 : 8 servings, Al 2 o 3 : 3 copies, B 2 o 3 : 20 parts, Fe 2 o 3 : 9 parts, MnO: 46 parts, TiO 2 : 8 servings.

[0039] Here transparent glaze selects ceramics to produce known transparent glaze for use and gets final product. The mineral crystal dry particles provided by the present invention contain a large amount of iron, manganese and titanium elements, and there will be multiple changes under different firing conditions and basic glaze components, especially in the way of combining with gl...

Embodiment 2

[0041] This embodiment provides a process for producing ceramics using the mineral crystal flower glaze provided in Embodiment 1.

[0042] A kind of ceramic tile production technology, it comprises the steps:

[0043] Step 1) Selecting known ceramic body powder to be stamped into brick adobe;

[0044] Step 2) applying a known top glaze on the surface of the green body by glazing to form a top glaze layer;

[0045] Step 3) printing on the glaze layer to form a printing layer;

[0046] Step 4) applying protective glaze on the surface of the printing layer;

[0047] Step 5) distributing the mineral crystal flower glaze, the mineral crystal flower glaze is calculated in parts by mass, and includes the following components: 100 parts of mineral crystal dry particles, 0-50 parts of transparent glaze, 60-80 parts of printing paste, and 0.2 parts of carboxymethyl cellulose parts, 25-40 parts of water, the chemical components of the dry mineral crystal grains are calculated in parts...

Embodiment 3

[0054] A kind of ceramic tile, its structure from bottom to top is as follows: including body layer, surface glaze layer, whitening glaze layer, printing pattern layer, powder-increasing flower glaze layer, color-helping flower glaze layer, protective glaze layer and mineral Crystal flower glaze layer.

[0055] Its preparation process comprises the following steps:

[0056] The present invention also provides a kind of production technology of ceramic brick, and it comprises the steps:

[0057] Step 1) raw materials for billet are prepared by batching and ball milling to obtain slurry, then iron removal, sieving, stale, spray milling and then sieving to obtain billet;

[0058] Step 2) Pressing and molding the blank by a press to prepare the blank;

[0059] Step 3) putting green body into drying kiln for drying;

[0060] Step 4) apply the surface glaze by glazing;

[0061] Step 5) adopt screen printing whitening glaze to carry out whitening;

[0062] Step 6) Carry out deco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com