Tripolyphosphazene-nucleated star-shaped organic blue-light material and preparation method therefor

A technology of tripolyphosphazene and blue light materials, which is applied in the fields of luminescent materials, organic chemistry, chemical instruments and methods, etc., to achieve the effects of comprehensive performance improvement, easy industrial production, and simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

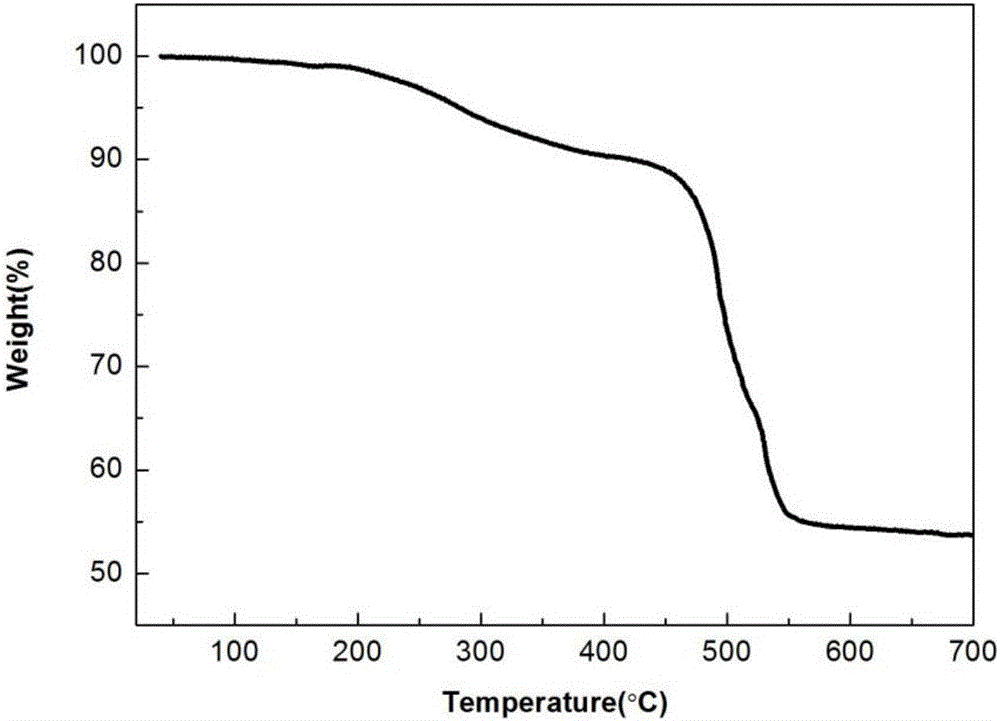

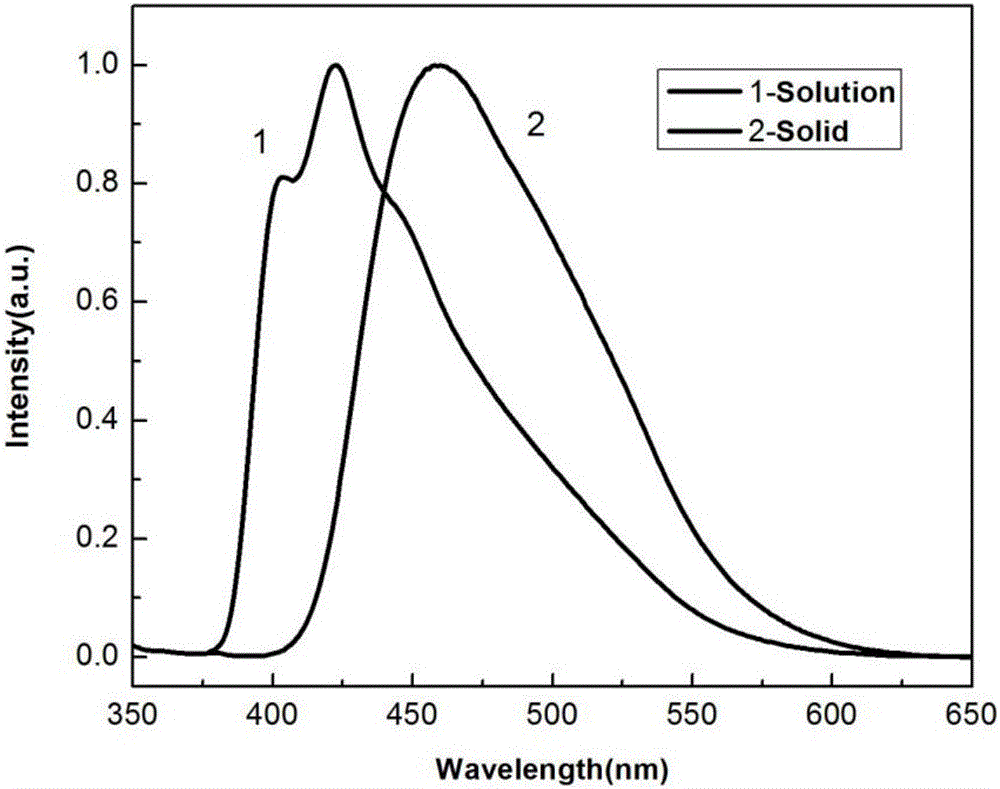

Embodiment 1

[0026] Example 1: Synthesis of compound 001, the specific preparation steps are as follows:

[0027] Step (1) Put 4.80g K 2 CO 3 (34.8mmol), 5.00g of p-bromophenol (29.0mmol) and 50mL of dry THF solution were added to a two-necked flask to form a white suspension. Stir at a constant temperature of 70°C for 1 hour. When the suspension becomes clear, drop 1.00g A dilute THF solution of hexachlorocyclotriphosphazene (2.90 mmol) was reacted at 70° C. for 48 hours. A white solid appeared to stop the reaction. The reaction liquid was filtered, the solid was filtered off, the filtrate was taken, and then extracted with saturated NaCl solution 3 times, with anhydrous MgSO 4 The organic layer was dried, filtered and evaporated, washed twice with methanol, and filtered and dried to obtain 3.14 g of the intermediate product with a yield of 92.7%.

[0028] Step (2) 1.170g of the above intermediate product (1.00mmol) prepared in step (1), 2M K 2 CO 3 The solution is 5mL, containing 2.00g anthra...

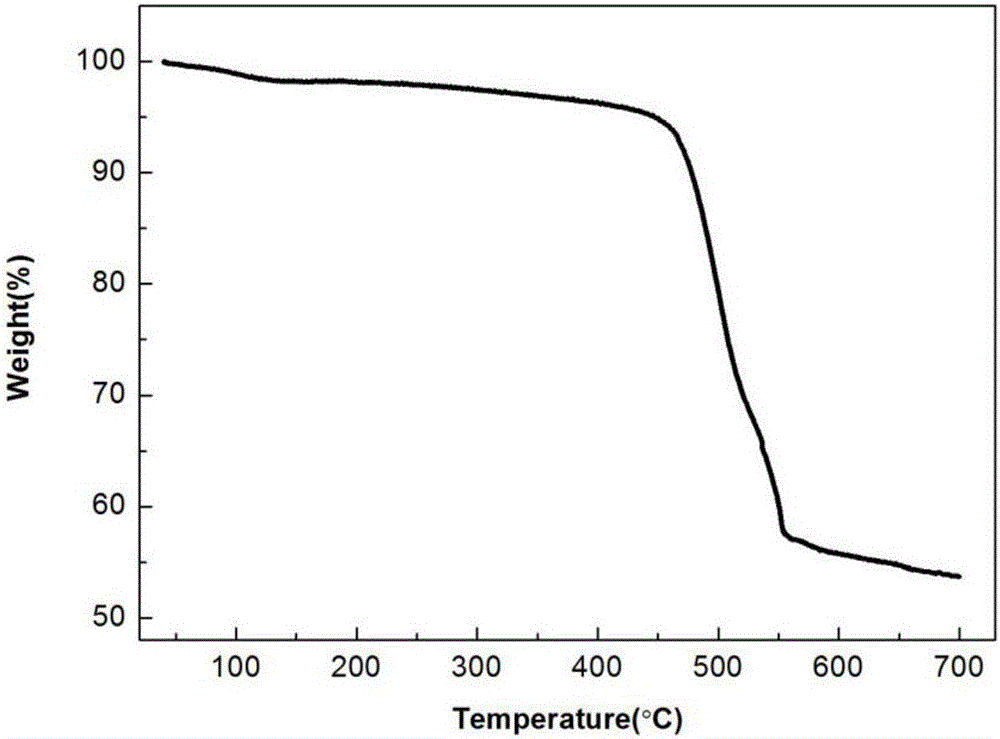

Embodiment 2

[0032] Example 2: Synthesis of compound 002, the specific preparation steps are as follows:

[0033] Step (1) Put 4.80g K 2 CO 3 (34.8mmol), 5.00g of tribromophenol (29.0mmol) and 50mL of dry THF were added to a two-necked flask to form a white suspension. Stir at a constant temperature of 70°C for 1 hour. When the suspension becomes clear, add 1.00g of six The dilute THF solution of chlorocyclotriphosphazene (2.90 mmol) was added to the clear liquid, and the reaction was kept at 70°C for 48 hours. The reaction was stopped when a white solid appeared. The reaction liquid was filtered, the solid was filtered off, the filtrate was taken, and then extracted with saturated NaCl solution 3 times, with anhydrous MgSO 4 The organic layer was dried, filtered and evaporated, washed twice with methanol, and filtered and dried to obtain 3.30 g of intermediate product 2, with a yield of 96.0%.

[0034] Step (2) 1.170g of the above intermediate product (1.00mmol) prepared in step (1), 2M K 2 CO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com