Pb<2+>-doped ultraviolet long-afterglow luminescent material and preparation method thereof

A technology of luminescent materials and foreign ministers, applied in luminescent materials, chemical instruments and methods, etc., to achieve the effects of enhanced ultraviolet afterglow intensity, simple operation, and excellent light-excited afterglow luminescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

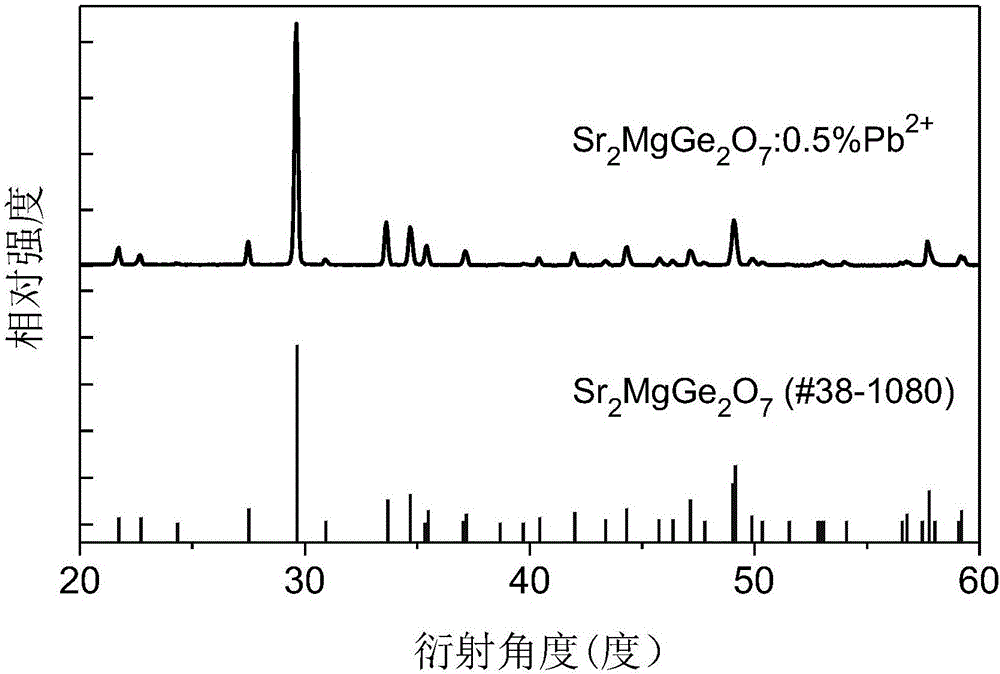

[0032] According to the following ingredients: UV long afterglow luminescent material Sr 2 MgGe 2 o 7 :Pb 2+ , with Sr 2 MgGe 2 o 7 as the matrix, doped with Pb 2+ is the active ion, where Pb 2+ The doping amount (accounting for the luminescent material) is 0.5 mol%. Accurately weigh strontium carbonate (SrCO 3 ) 1.7716g, magnesium oxide (MgO) 0.24g, germanium oxide (GeO 2 ) 1.26g, lead oxide (PbO) 0.0067g and boron oxide (B 2 o 3 ) 0.0165g. Put the above raw materials in an agate mortar and grind for about 1 hour, mix the raw materials thoroughly, then transfer them to a corundum crucible, and pre-fire them at 900°C for 2 hours. After the calcined powder is reground, use a powder tablet press to press about 1 g of the powder into a disc with a diameter of about 15 mm and a thickness of about 1 mm. Finally, the formed wafer was sintered at 1320°C for 3 hours to obtain Sr 2 MgGe 2 o 7 :Pb 2+ UV long afterglow luminescent material.

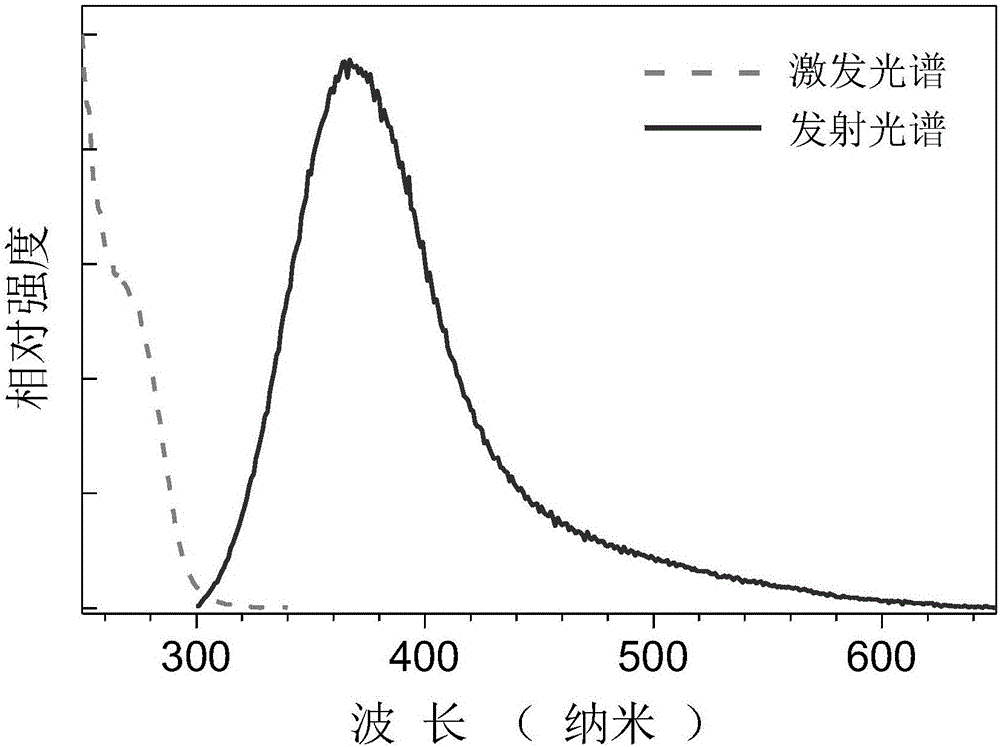

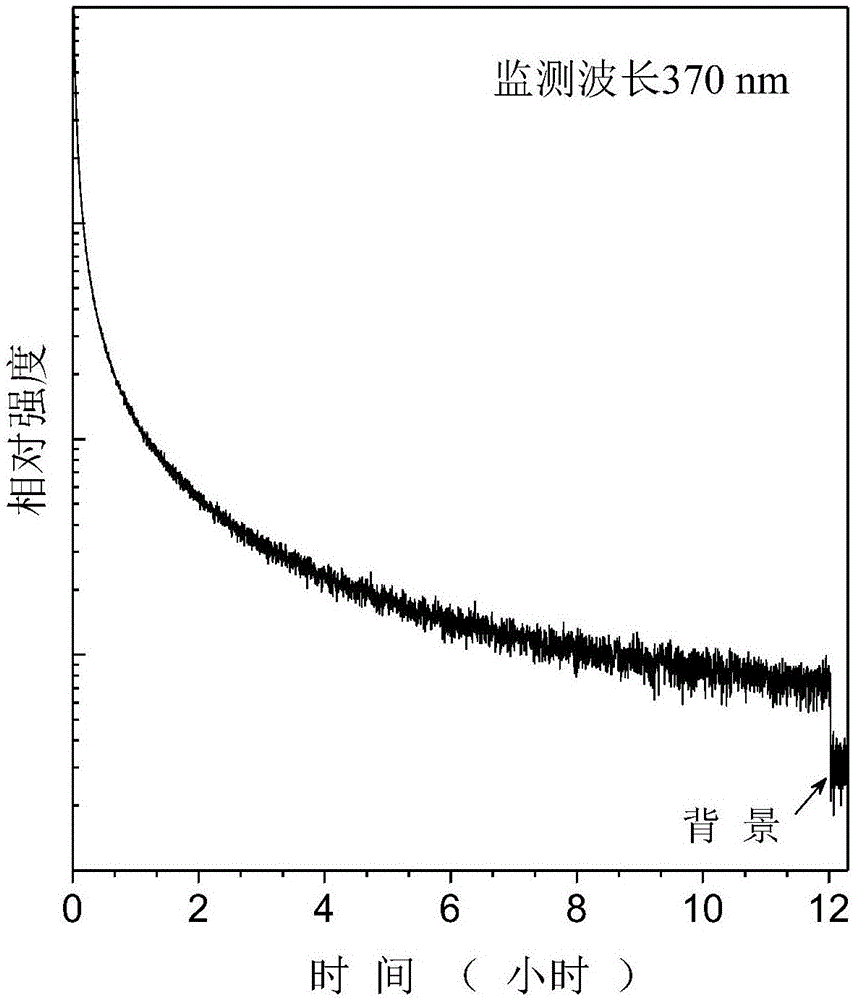

[0033] The sample prepared ...

Embodiment 2

[0039] According to the following ingredients: UV long afterglow luminescent material Sr 2 MgGe 2 o 7 :Pb 2+ , with Sr 2 MgGe 2 o 7 as the matrix, doped with Pb 2+ is the active ion, where Pb 2+ The doping amount (accounting for the luminescent material) is 1mol%; accurately weigh strontium carbonate (SrCO 3 ) 1.7672g, magnesium oxide (MgO) 0.24g, germanium oxide (GeO 2 ) 1.26g, lead oxide (PbO) 0.0134g and boron oxide (B 2 o 3 ) 0.0165g. Put the above raw materials in an agate mortar and grind for about 1 hour, mix the raw materials thoroughly, then transfer them to a corundum crucible, and pre-fire them at 800°C for 2 hours. After the pre-fired powder is reground, about 1 g of the powder sample is pressed into a disc with a diameter of about 15 mm and a thickness of about 1 mm using a powder tablet press. Finally, the formed wafer was sintered at 1350°C for 2 hours to obtain Sr 2 MgGe 2 o 7 :Pb 2+ UV long afterglow luminescent material.

Embodiment 3

[0041] According to the following ingredients: UV long afterglow luminescent material Sr 2 MgGe 2 o 7 :Pb 2+ , with Sr 2 MgGe 2 o 7 as the matrix, doped with Pb 2+ is the active ion, where Pb 2+ The doping amount (accounting for the luminescent material) is 0.1mol%; accurately weigh strontium carbonate (SrCO 3 ) 1.7751g, magnesium oxide (MgO) 0.24g, germanium oxide (GeO 2 ) 1.26g, lead oxide (PbO) 0.0014g and boron oxide (B 2 o 3 ) 0.0165g. Grind the above raw materials in an agate mortar for about 1 hour, mix the raw materials thoroughly, then transfer to a corundum crucible, and pre-fire at 800°C for 3 hours. After the pre-fired powder is reground, about 1 g of the powder sample is pressed into a disc with a diameter of about 15 mm and a thickness of about 1 mm using a powder tablet press. Finally, the formed wafer was sintered at 1300°C for 3 hours to obtain Sr 2 MgGe 2 o 7 :Pb 2+ UV long afterglow luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com