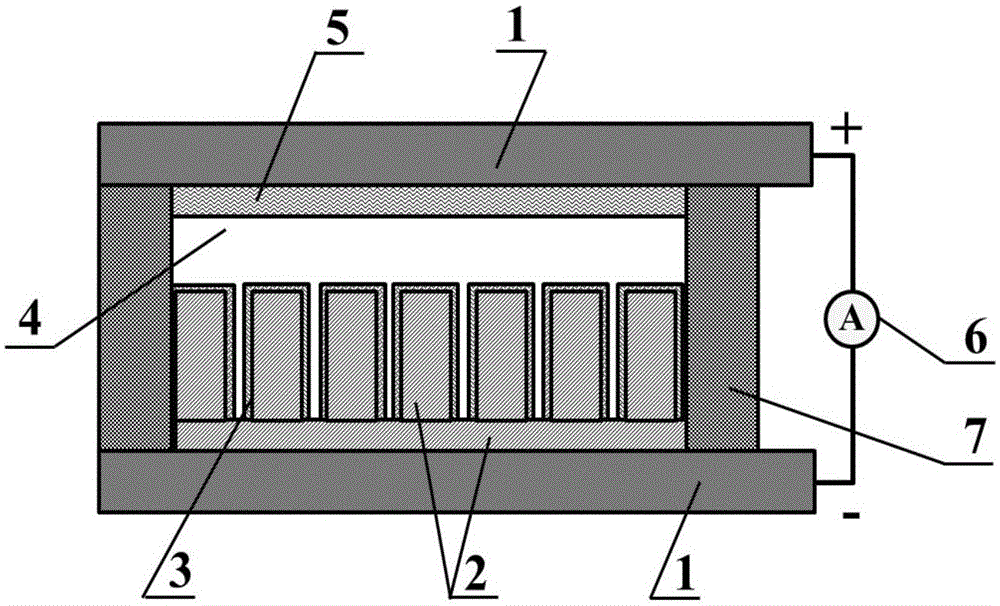

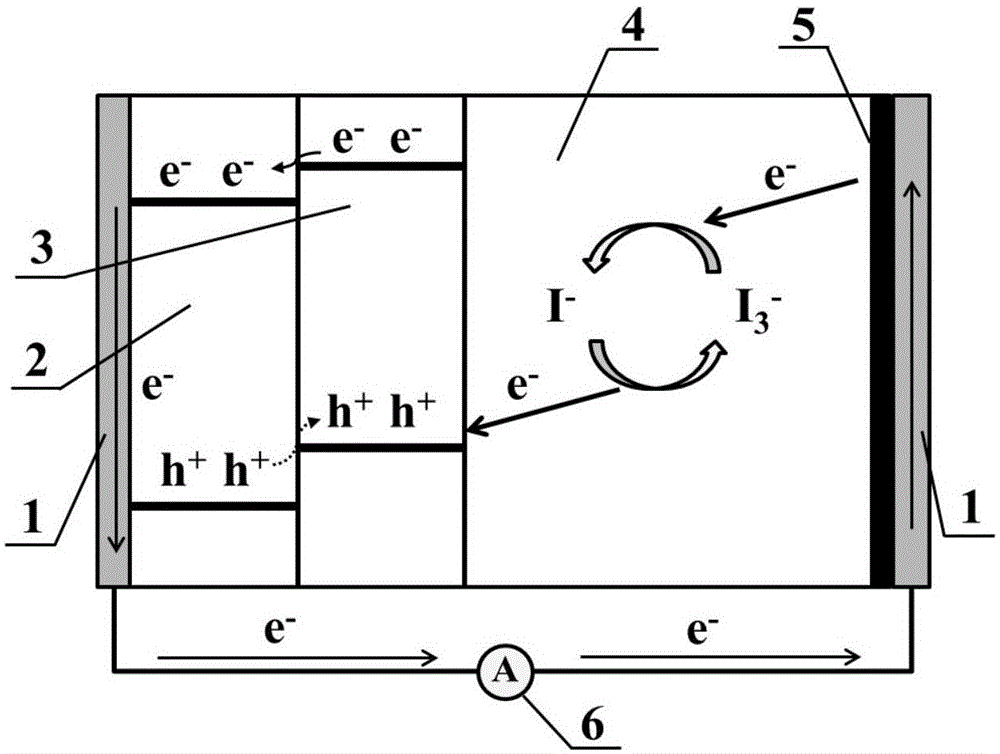

Self-driven TiO2 ultraviolet detector and preparation and application thereof

A UV detector, self-driven technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., to achieve simple preparation, improve photoresponse efficiency, and reduce recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

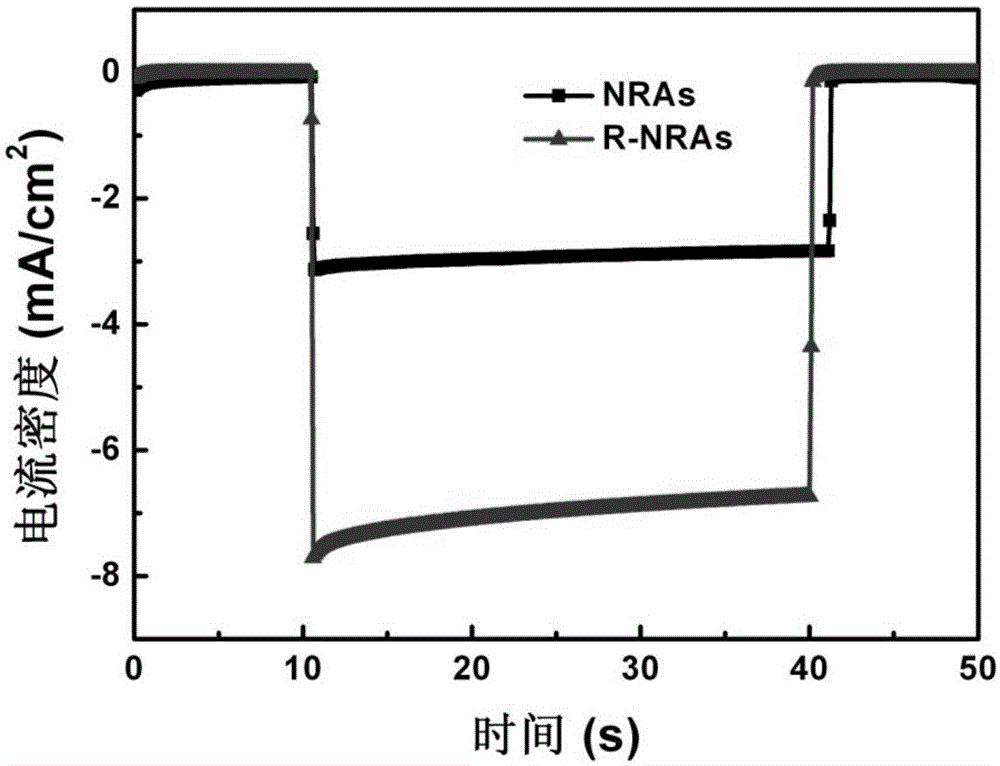

Embodiment 1

[0030] 1) Place the FTO transparent conductive substrate in acetone, isopropanol, ethanol and deionized water for 20 minutes, and then dry it under air flow;

[0031] 2) Place the pre-cleaned FTO transparent conductive substrate (conductive side down) in a polytetrafluoroethylene-lined hydrothermal kettle, add 0.15 mL of tetrabutyl titanate containing HCl and H 2 O volume ratio of 1:1 mixed solution, at 180 ℃ for 2h, grow TiO on the FTO substrate 2 Nanorod array, the nanorod length is about 2μm; XRD results show that the synthesized nanorod array is a pure rutile phase.

[0032] 3) TiO obtained in step (2) 2 The rutile phase nanorod arrays were placed in a three-electrode electrolytic cell, and TiO 2 Electrode, saturated calomel electrode and Pt electrode are research electrode, reference electrode and counter electrode. Choose a constant voltage of -1.8V, and restore it for 2s;

[0033] 4) Put the clean FTO obtained in step (1) into the magnetron sputtering equipment, use...

Embodiment 2

[0039] 1) Place the FTO transparent conductive substrate in acetone, isopropanol, ethanol and deionized water for 20 minutes, and then dry it under air flow;

[0040] 2) Place the pre-cleaned FTO transparent conductive substrate (conductive side down) in a polytetrafluoroethylene-lined hydrothermal kettle, add 0.15 mL of tetrabutyl titanate containing HCl and H 2O volume ratio of 1:1 mixed solution, at 180 ℃ for 2h, grow TiO on the FTO substrate 2 Nanorod array, the nanorod length is about 2μm; XRD results show that the synthesized nanorod array is a pure rutile phase.

[0041] 3) Put the clean FTO obtained in step (1) into the magnetron sputtering equipment, use the Pt metal target as the target material, and firstly vacuumize the equipment for 10 -5 Pa, and then pass Ar gas into it, adjust the sputtering pressure to 1Pa, and sputter for 1min under the direct current mode of 60W to obtain a layer of Pt conductive electrode, and leave a round hole on it for future use.

[00...

Embodiment 3

[0045] 1) Place the FTO transparent conductive substrate in acetone, isopropanol, ethanol and deionized water for 20 minutes, and then dry it under air flow;

[0046] 2) Place the pre-cleaned FTO transparent conductive substrate (conductive side down) in a polytetrafluoroethylene-lined hydrothermal kettle, add 0.15 mL of tetrabutyl titanate containing HCl and H 2 O volume ratio of 1:1 mixed solution, at 180 ℃ for 2h, grow TiO on the FTO substrate 2 Nanorod array, the nanorod length is about 2μm; XRD results show that the synthesized nanorod array is a pure rutile phase.

[0047] 3) TiO obtained in step (2) 2 The rutile phase nanorod arrays were placed in a three-electrode electrolytic cell, and TiO 2 Electrode, saturated calomel electrode and Pt electrode are research electrode, reference electrode and counter electrode. Choose a constant voltage of -1.6V, and restore it for 2s;

[0048] 4) Put the clean FTO obtained in step (1) into the magnetron sputtering equipment, use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com