Oxide nanowire preparation method based on quantum dot modification

A nanowire and oxide technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low proton conductivity, low utilization rate of nano-scale active components, and high cost of catalyst preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

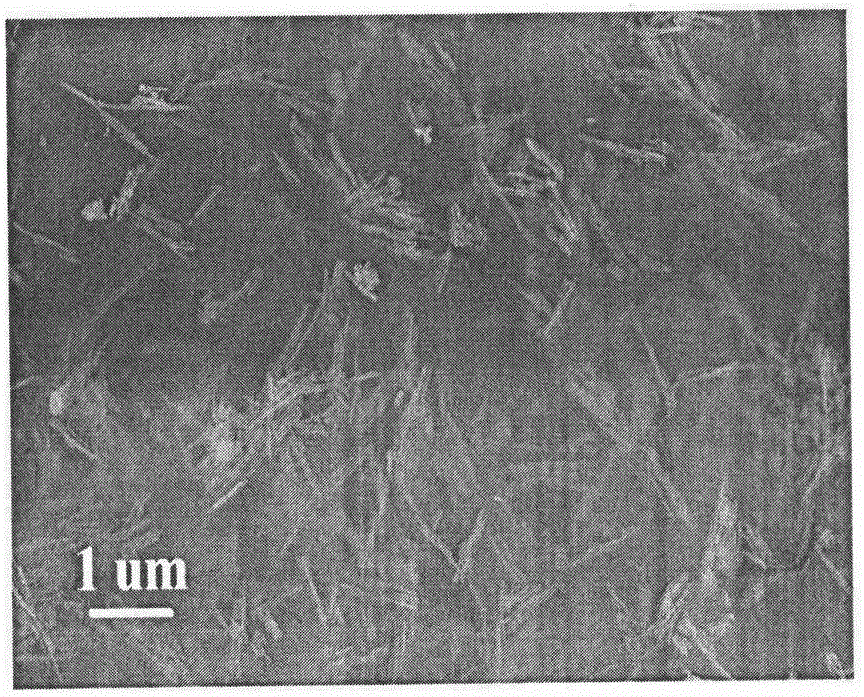

[0008] Specific embodiment one: a kind of oxide nanowire preparation method based on quantum dot modification in the present invention can be realized according to the following steps: 1. Preparation of CeO by microwave-assisted ethylene glycol method 2 Nanowire; Two, the CeO prepared in step one 2 The nanowires were dispersed in a crucible filled with water. During the ultrasonic dispersion process, a certain amount of ionic liquid was pipetted with a pipette gun, and ultrasonically dispersed into a uniform slurry; 3. Dry the step-2 slurry at 70°C to obtain A compound of ionic liquid uniformly distributed on the surface, and then the compound is kept in a tube furnace under the protection of argon at 400°C for 60-90 minutes, and then cooled to room temperature with the furnace under the protection of argon to obtain nitrogen-doped carbon Modified CeO 2 Nanowires. The nanowires can be titanium dioxide nanowires, oxide nanowires such as Fe and Co, and the like.

[0009] Nitr...

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment differs from Embodiment 1 in that: the way of adding microwave heating in step 1 is direct heating; the time required for direct heating is 30-60 minutes. Its steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the ionic liquid in Step 1 is polyvinylpyrrolidone or 1-ethyl-3-methylimidazolium dicyanamide. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com