A kind of carbon cage type silicon-graphite composite material and preparation method thereof

A composite material and graphite technology, applied in the preparation/purification of graphite and carbon, structural parts, etc., can solve the problems of lithium ion consumption, cycle performance deterioration, volume expansion effect, etc., to increase conductivity and stability, and suppress volume Expansion effect, the effect of optimizing the skeleton structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

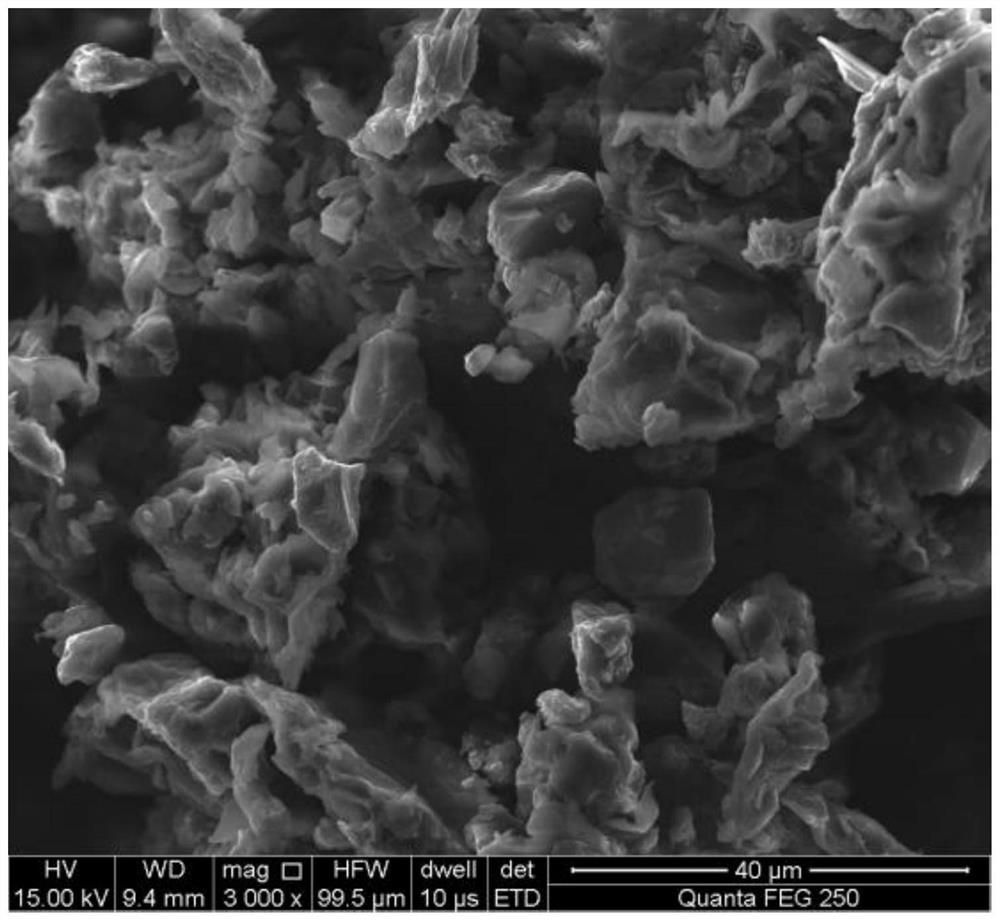

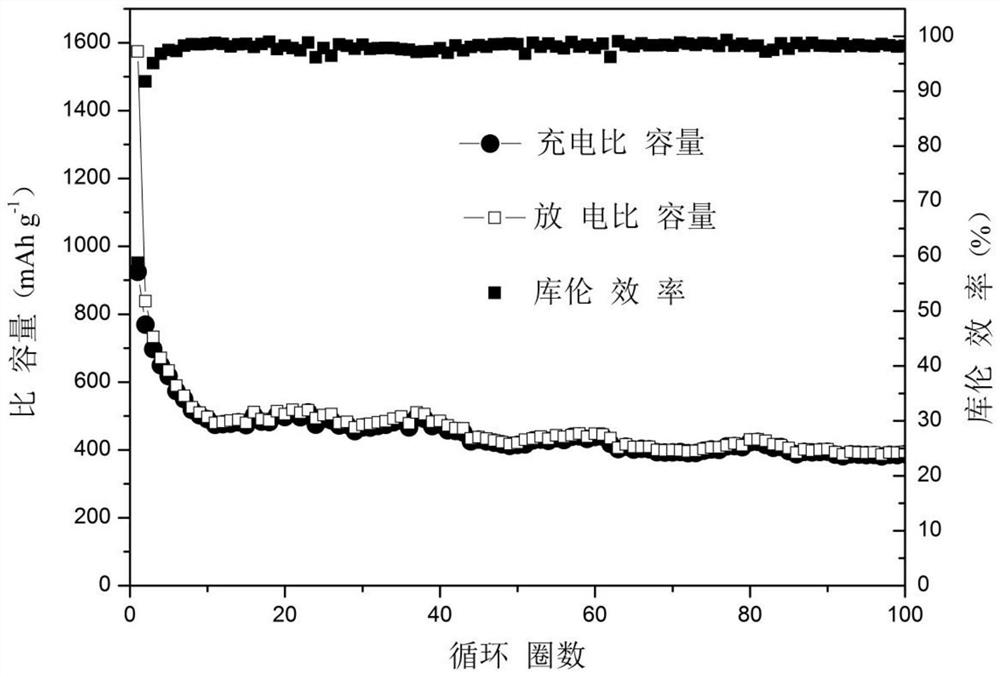

Image

Examples

preparation example Construction

[0034] A kind of preparation method of carbon cage type silicon-graphite material, comprises the steps:

[0035] Step 1: Add 2.5-3.5 parts of graphite into 80-100 parts of concentrated sulfuric acid solution in parts by mass, and stir at room temperature to obtain suspension 1. The graphite may be natural graphite and / or artificial graphite. Concentrated sulfuric acid plays the role of intercalation and activation to oxidize the edge of graphite and SO 4 2﹣ intercalation. Preferably, the mass percent concentration of the concentrated sulfuric acid solution used is 95%-98%, and the stirring time is 3-4 hours. A mixture of concentrated sulfuric acid and phosphoric acid can also be used.

[0036] Step 2: Pour suspension 1 into 7-9 parts of potassium permanganate solution, and stir at room temperature to obtain suspension 2; pour suspension 2 into 50-65 parts of hydrogen peroxide solution, and stir at room temperature to obtain suspension 3. The main function of potassium perm...

Embodiment 1

[0044] Step 1: Add 3 g of natural graphite into 50 mL of 95%-98% concentrated sulfuric acid solution, and stir at room temperature for 3 hours to obtain suspension 1;

[0045] Step 2: Pour suspension 1 into 7-9 g of 50% potassium permanganate solution by mass, stir at room temperature for 3 hours to obtain suspension 2, and pour suspension 2 into 50 mL of 30% hydrogen peroxide by mass solution, stirred at room temperature for 2 h to obtain suspension 3;

[0046] Step 3, the suspension 3 was washed with distilled water until pH = 6.76, 1 g of nano-scale silicon powder was added, and then 1 g of polyvinylpyrrolidone was added to stir and ultrasonically disperse for 20 minutes each to obtain a suspension 4.

[0047] Step 4: Add 2 g of sucrose to the suspension 4, add 1 g of citric acid, stir for 20 minutes, and sonicate for 30 minutes to obtain a suspension 5, and put the suspension 5 into an oven to dry at 110° C. for 3 hours;

[0048] Step 5: Put the dried sample into a tube f...

Embodiment 2

[0051] Step 1: Add 3 g of artificial graphite into 50 mL of 95%-98% concentrated sulfuric acid solution, stir at room temperature for 3 hours to obtain suspension 1;

[0052] Step 2: Pour suspension 1 into 7-9 g of 50% potassium permanganate solution by mass, and stir at room temperature for 3 hours to obtain suspension 2; pour suspension 2 into 50 mL of 30% hydrogen peroxide by mass solution, stirred at room temperature for 2 h to obtain suspension 3;

[0053] Step 3, the suspension 3 was washed with distilled water until pH = 6.84, 1 g of nano-scale silicon powder was added, and then 1 g of polyvinylpyrrolidone was added to stir and ultrasonically disperse for 20 minutes each to obtain suspension 4.

[0054] Step 4: Add 2 g of sucrose to the suspension 4, add 1 g of citric acid, stir for 20 minutes, and sonicate for 30 minutes to obtain a suspension 5, and put the suspension 5 into an oven to dry at 110° C. for 3 hours;

[0055] Step 5: Put the dried sample into a tube furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com