Carbon-tin nano composite material as well as preparation method and application thereof

A nano-composite material and composite material technology, applied in the field of carbon-tin nano-composite materials and their preparation, can solve the problems of unresistable macroscopic mechanical properties, limited commercialization, easy cracking and crushing of electrodes, etc., and achieve the suppression of volume expansion effect , Improve electrical conductivity, improve the effect of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a preparation method of carbon-tin nanocomposite material, comprising the following steps:

[0025] (1) mixing tin tetrachloride pentahydrate solution with helical carbon nanofiber dispersion liquid to carry out hydrolysis reaction to obtain tin dioxide / helical carbon nanofiber composite material;

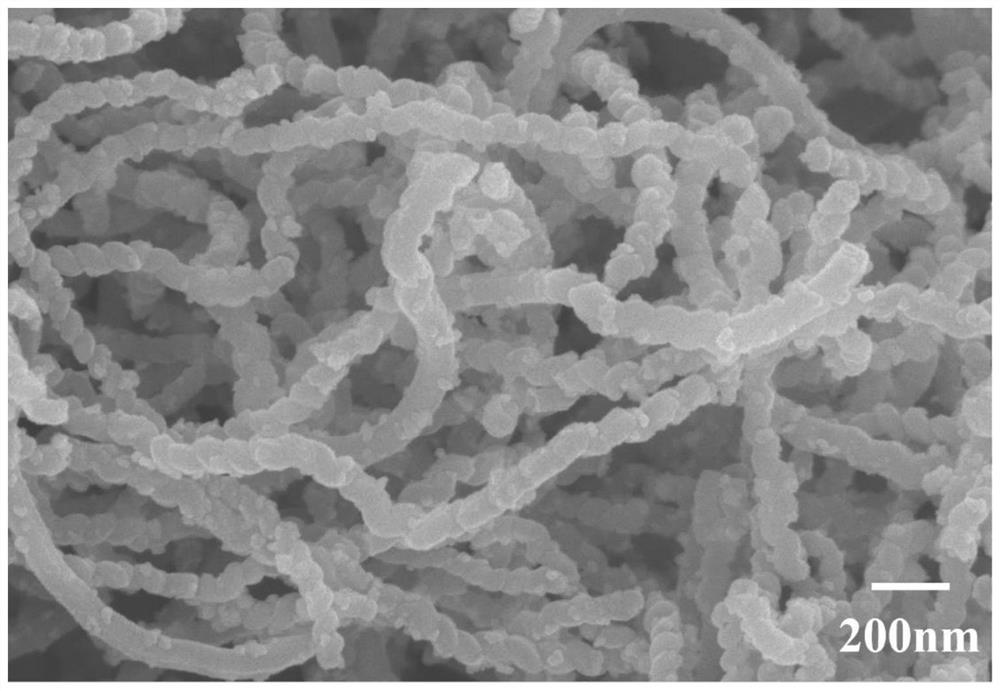

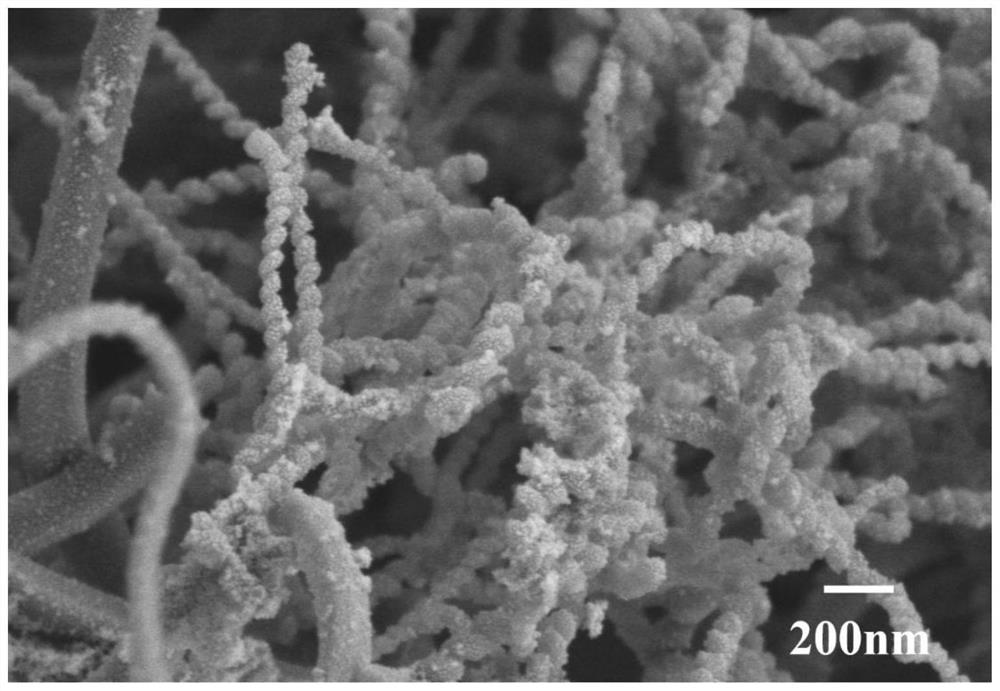

[0026] (2) reducing the tin dioxide / spiral carbon nanofiber composite material obtained in the step (1) to obtain a tin / spiral nanocarbon fiber composite material;

[0027] (3) carbon coating is performed on the surface of the tin / spiral carbon nanofiber composite material obtained in the step (2) by a vapor deposition method to obtain a carbon-tin nanocomposite material.

[0028] In the present invention, unless otherwise specified, the raw materials used are conventional commercially available products in the field.

[0029] In the invention, the tin tetrachloride pentahydrate solution is mixed with the helical nano carbon fiber dispersion liquid to...

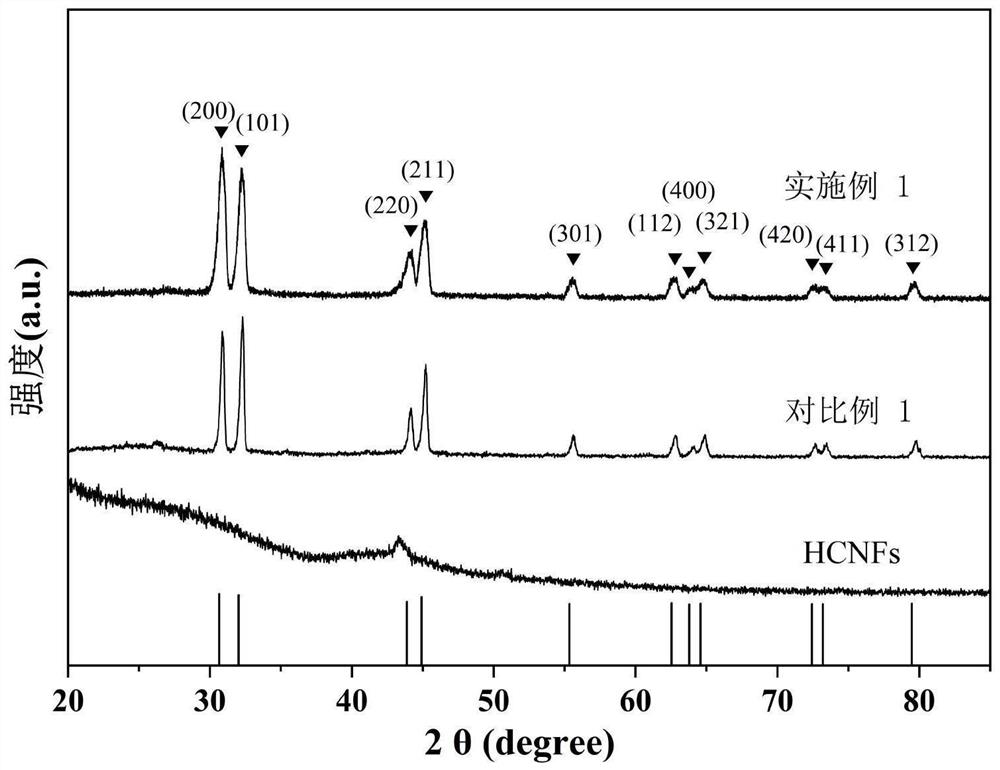

Embodiment 1

[0055] Preparation method of carbon tin nanocomposite

[0056] (1) The tin tetrachloride pentahydrate solution was added dropwise to the helical carbon nanofiber dispersion at a rate of 0.5 mL / min. After the dropwise addition, the hydrolysis reaction was carried out at 80 °C for 3 h, and the product of the hydrolysis reaction was filtered by vacuum suction. , and dried at 80°C for 12 hours to obtain a tin dioxide / spiral carbon nanofiber composite material; the mass ratio of tin tetrachloride pentahydrate in the tin tetrachloride pentahydrate solution to the spiral nanocarbon fiber in the spiral nanocarbon fiber dispersion liquid is: 3:1;

[0057] The preparation method of the tin tetrachloride pentahydrate solution is as follows: at room temperature, weigh 0.3 g of tin tetrachloride pentahydrate in a 50 mL beaker, measure 50 mL of deionized water and mix with tin tetrachloride pentahydrate ultrasonically for 10 min. ;

[0058] The preparation method of the helical carbon nan...

Embodiment 2

[0066] The carbon-tin nanocomposite was prepared according to the method of Example 1 and named C / Sn / HCNFs-0.13;

[0067] The difference from Example 1 is that 0.4g of tin tetrachloride pentahydrate is weighed when preparing the tin tetrachloride pentahydrate solution in the step (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com