Silicon-carbon composite material as well as preparation method and application thereof

A technology of silicon-carbon composite materials and carbon nanometers, which is applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of easy falling off, broken, low mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing a silicon-carbon composite material, comprising the following steps:

[0053] Step 1: Foam Nickel Pretreatment

[0054] Thickness 2mm, bulk density 5g / cm 3 , soak nickel foam with a purity ≥ 90% in 2M hydrochloric acid, 100W ultrasonic cleaning for 20 minutes, and then clean the residual hydrochloric acid with deionized water;

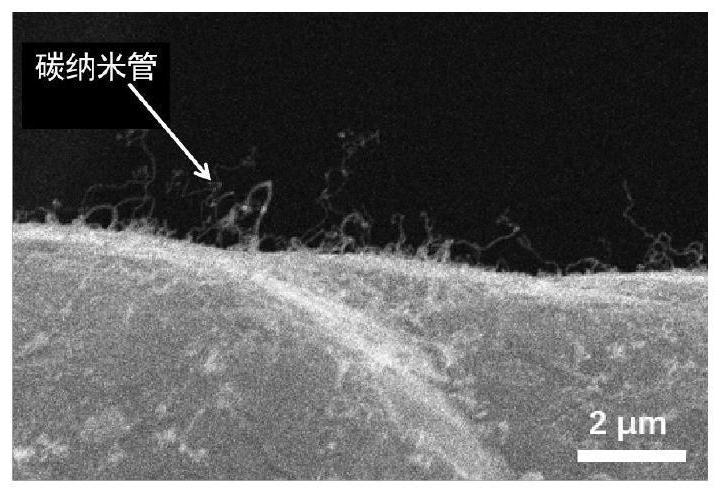

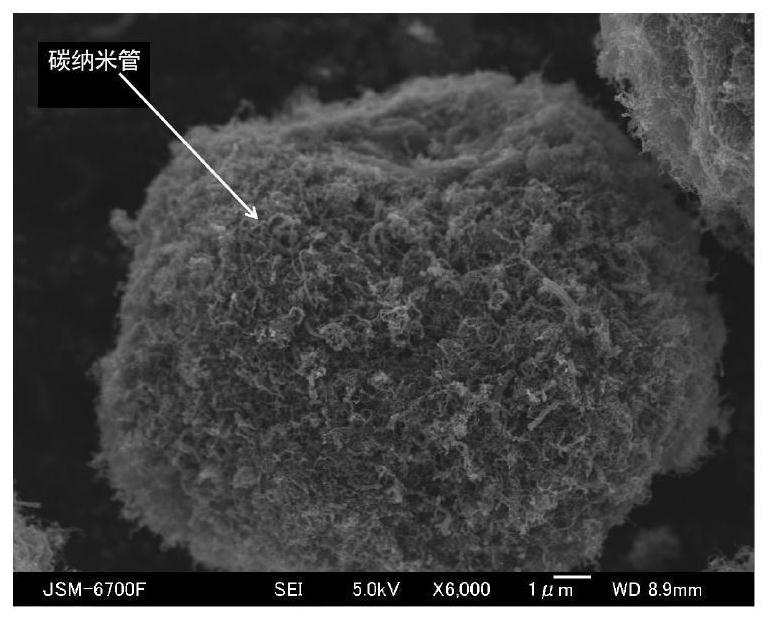

[0055] Step 2: Loading of carbon nano toughening agent

[0056] Disperse carbon nanotubes with a diameter of 10-50nm, a length of 1-50μm, and a carbon content ≥ 95% in an aqueous solution of cetyltrimethylammonium bromide with a concentration of 3g / L to form a carbon nanotube with a concentration of 3g / L Solution A, then evenly coat solution A on the nickel foam treated in step 1, then dry at -0.1MPa for 6h, the loading of carbon nanotubes on the nickel foam is 0.1-5mg / cm 2 ;

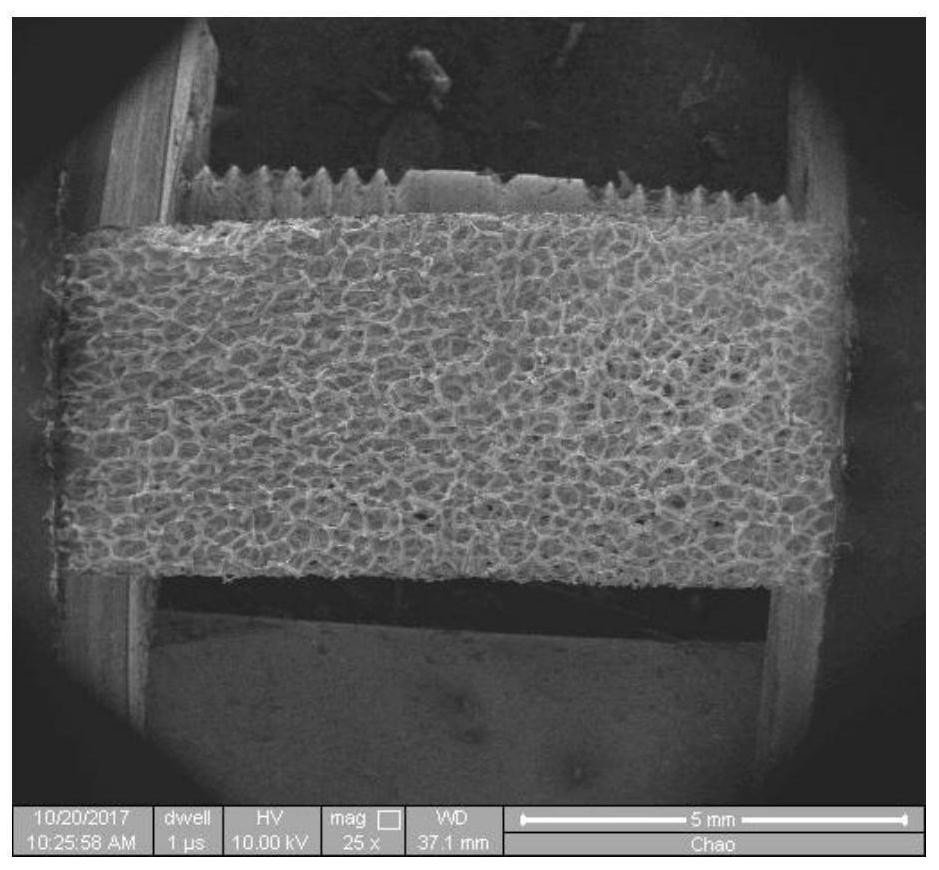

[0057] Step 3: CVD growth graphene foam

[0058] The nickel foam obtained in step 2 is fed into a tube furnace at -0.1-0.15MPa to raise the te...

Embodiment 2

[0072] A method for preparing a silicon-carbon composite material, comprising the following steps:

[0073] Step 1: Foam Copper Pretreatment

[0074] Thickness 2mm, bulk density 5g / cm 3 , soak copper foam with a purity ≥ 90% in 2M hydrochloric acid, 100W ultrasonic cleaning for 20min, and then clean the residual hydrochloric acid with deionized water;

[0075] Step 2: Loading of carbon nano toughening agent

[0076] Disperse graphene nanobelts with a diameter of 10-50nm, a length of 1-50μm, and a carbon content ≥ 95% in an aqueous solution of sodium dodecyl sulfate with a concentration of 3g / L to form a solution A with a concentration of 2g / L of graphene nanobelts , and then uniformly coat solution A on the copper foam treated in step 1, then dry at -0.1MPa for 5h, and the loading capacity of graphene nanoribbons on the copper foam is 2mg / cm 2 ;

[0077] Step 3: CVD growth graphene foam

[0078] Put the copper foam obtained in step 2 into a tube furnace at -0.1-0.15MPa an...

Embodiment 3

[0092] A method for preparing a silicon-carbon composite material, comprising the following steps:

[0093] Step 1: Foam Iron Pretreatment

[0094] Thickness 5mm, bulk density 5g / cm 3 , Foam iron with a purity ≥ 90% is soaked in 2M hydrochloric acid, 100W ultrasonic cleaning for 20min, and then the residual hydrochloric acid is cleaned with deionized water;

[0095] Step 2: Loading of carbon nano toughening agent

[0096] Disperse carbon nanofibers with a diameter of 10-50nm, a length of 1-50μm, and a carbon content ≥ 95% in an aqueous solution of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer with a concentration of 3g / L , form a solution A with a carbon nanofiber concentration of 3g / L, and then uniformly coat solution A on the iron foam treated in step 1, and then dry at -0.1MPa for 6h, and the loading of carbon nanofibers on the iron foam is 0.1 -5mg / cm 2 ;

[0097] Step 3: CVD growth graphene foam

[0098] Put the iron foam obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com