Pole sheet preparation method for improving performance of silicon-based negative electrode lithium ion battery

A lithium-ion battery, silicon-based negative electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult wide application, cumbersome processes, etc., and achieve the effects of easy industrialization, simple process, and improved first-time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

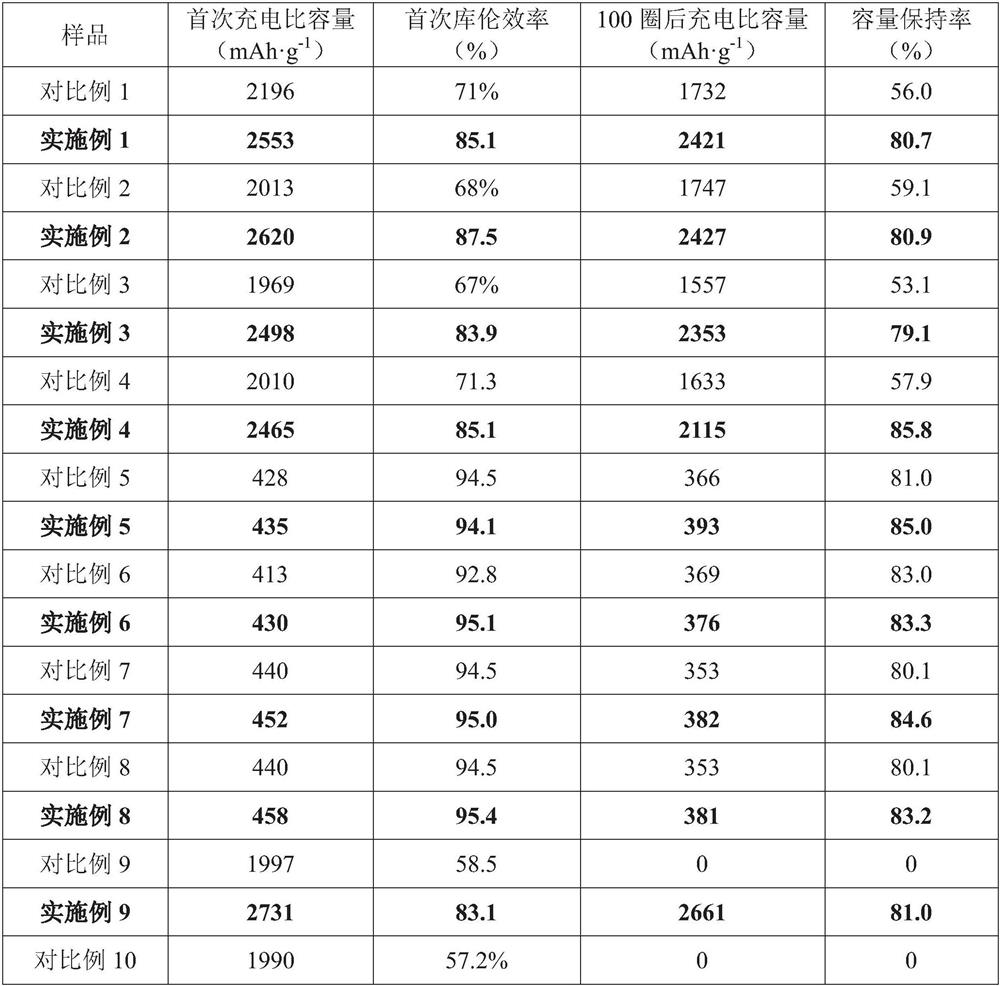

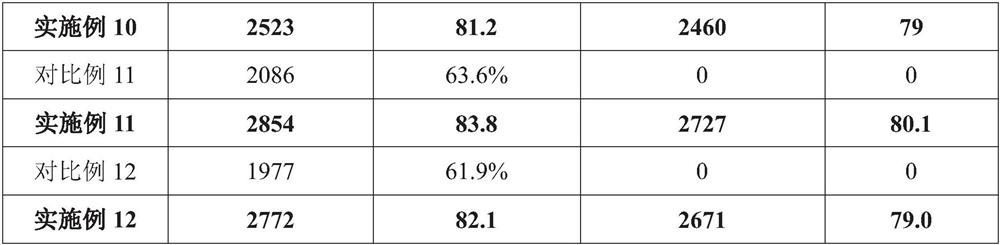

[0024] Weigh 0.021g of trimesic acid and 0.011g of p-phenylenediamine, respectively dissolve them in 1mL of absolute ethanol + 2mL of deionized water mixture to obtain solution 1 and solution 2, according to the mass ratio of 16:2:1:1 Weigh 0.64g carbon-coated silicon anode material (~Si content: 98%), 0.08g Super-P, 0.04g CMC, 0.04g SBR, add the prepared solution 1 and solution 2, and then magnetically mix and stir to form a slurry ; then evenly coat it on the surface of copper foil, and dry it at 70°C for 40min; then put it in a vacuum oven and dry it at 120°C for 15h; Under charge and discharge cycle test. The test results are shown in Table 1, which shows that the first Coulombic efficiency and cycle performance of the modified silicon-based negative electrode sheet are better than that of the unmodified electrode sheet.

Embodiment 2

[0026] Weigh 0.021g of trimesic acid and 0.011g of hydroquinone, respectively dissolve them in 1mL of absolute ethanol + 2mL of deionized water mixture to obtain solution 1 and solution 2, and weigh them respectively according to the mass ratio of 16:2:2. Take 0.64g of carbon-coated silicon negative electrode material (~Si content: 98%), 0.08g of Super-P, 0.08g of acrylic glue, add the prepared solution 1 and solution 2, and then magnetically mix and stir to form a slurry; then mix it evenly Coated on the surface of copper foil and dried at 70°C for 40 minutes; then placed in a vacuum oven and dried at 120°C for 15 hours; finally sliced into button cells, and charged and discharged at a current density of 500mA / g test. The test results are shown in Table 1, which shows that the first Coulombic efficiency and cycle performance of the modified silicon-based negative electrode sheet are better than that of the unmodified electrode sheet.

Embodiment 3

[0028] Weigh 0.021g of trimesic acid and 0.019g of p-phenylenediamine o-sulfonic acid, respectively dissolve them in 1mL of absolute ethanol + 2mL of deionized water mixture to obtain solution 1 and solution 2, in a mass ratio of 16:2: 2 Weigh 0.64g of carbon-coated silicon negative electrode material (~Si content: 98%), 0.08g of Super-P, and 0.08g of sodium alginate, add the prepared solution 1 and solution 2, and then magnetically mix and stir to form a slurry; Then it is evenly coated on the surface of copper foil, and dried at 70°C for 40min; then placed in a vacuum oven and dried at 120°C for 15h; finally sliced and prepared into a button battery, at a current density of 500mA / g Carry out a charge-discharge cycle test. The test results are shown in Table 1, which shows that the first Coulombic efficiency and cycle performance of the modified silicon-based negative electrode sheet are better than that of the unmodified electrode sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com