Preparation method of CZTSSe thin film and application of CZTSSe thin film in lithium ion battery

A thin film and plasma technology, applied in the field of lithium-ion battery preparation, can solve the problems affecting the performance of materials, uneven crystallinity of prepared materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

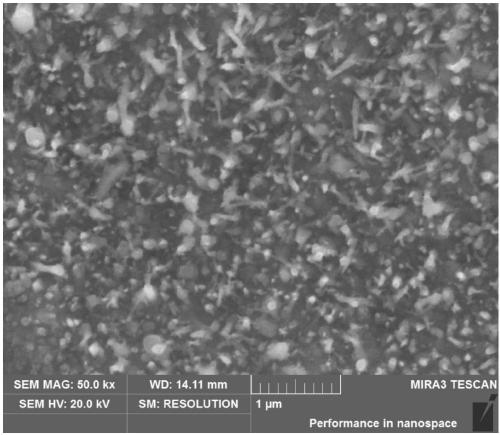

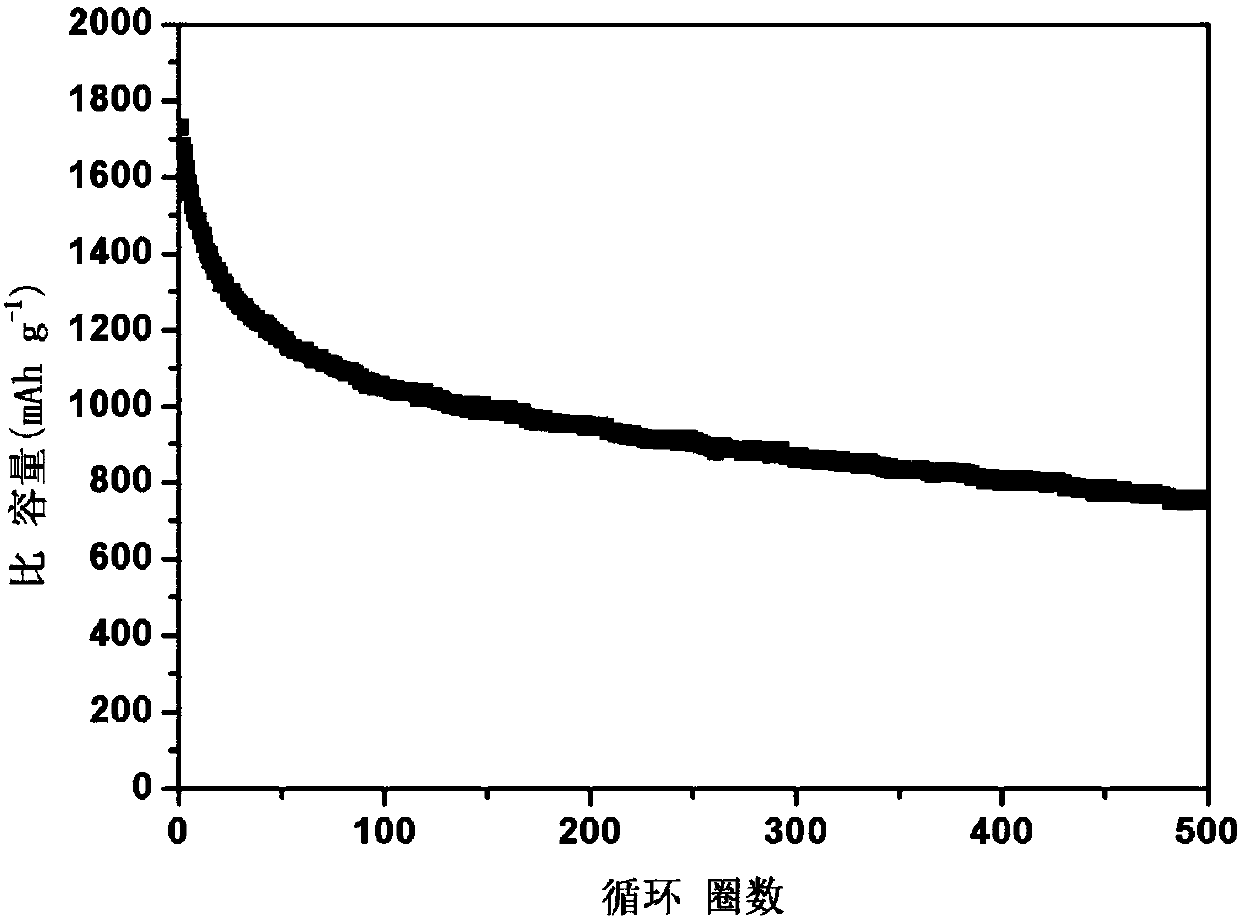

[0044] Soak the copper foil in 10wt% hydrochloric acid for 12 hours, dry it with alcohol after cleaning and cut it into small pieces of 2cm×2cm. Coat its A side with chloroform in which 5g of Se powder is dissolved, and dry it. Then fix the copper foil on the target stage, and control the sputtering of the material to the B surface. The target material is Cu, Zn, Sn target, three targets co-sputtering, and the atmosphere is adjusted to H 2 S, the total addition amount of controlled atmosphere is 220ml. At the same time, the heating program of the substrate was started, and the temperature was raised to 300°C. After pre-sputtering for 10mins, remove the baffle, adjust the power to 60W, and sputter for 60mins. Finally, the CZTSSe film obtained by sputtering was placed in a tube furnace, and the temperature was raised to 800° C. at a rate of 5° C. / min for high-temperature calcination for 100 mins to obtain the CZTSSe film. The thickness of the film is 0.74 μm, and the atomic r...

Embodiment 2

[0049] Soak the copper foil in 12wt% hydrochloric acid for 12 hours, dry it with alcohol after cleaning and cut it into small pieces of 2cm×2cm. Coat its A side with chloroform in which 5g of Se powder is dissolved, and dry it. Then fix the copper foil on the target stage, and control the sputtering of the material to the B surface. The target material is Cu, Zn, and Sn targets for three-target co-sputtering, and the atmosphere is adjusted to Ar / H 2 S(1:1), the total amount of control gas added is 400ml. At the same time, the heating program of the substrate was started, and the temperature was raised to 500°C. After pre-sputtering for 10mins, remove the baffle, adjust the power to 40W, and sputter for 60mins. Finally, the CZTSSe film obtained by sputtering was placed in a tube furnace, and the temperature was raised to 900° C. at a rate of 5° C. / min for high-temperature calcination for 30 minutes to obtain the CZTSSe film. The thickness of the film is 0.68 μm, and the atom...

Embodiment 3

[0052] Soak the copper foil in 15wt% sulfuric acid for 12h, dry it with alcohol after cleaning and cut it into small pieces of 2cm×2cm. Coat its A side with chloroform in which 5g of Se powder is dissolved, and dry it. Then fix the copper foil on the target stage, and control the sputtering of the material to the B surface. The target material is Cu, Zn, and Sn targets for three-target co-sputtering, and the atmosphere is adjusted to Ar / H 2 S (1:10), the total amount of control gas added is 200ml. At the same time, the heating program of the substrate was started, and the temperature was raised to 250°C. After pre-sputtering for 10mins, remove the baffle, adjust the power to 80W, and sputter for 10mins. Finally, the CZTSSe film obtained by sputtering was placed in a tube furnace, and the temperature was raised to 650° C. at a rate of 10° C. / min for high-temperature calcination for 180 minutes to obtain the CZTSSe film. The thickness of the film is 0.80 μm, and the atomic ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com