Preparation method of Gamma alumina fiber

A technology of alumina fiber and fiber, which is applied in the field of preparation of Gamma alumina fiber, can solve the problems of unsuitable catalyst carrier, low activity, low specific surface area, etc., achieve high specific surface area, high specific surface activity, and simple technical route Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

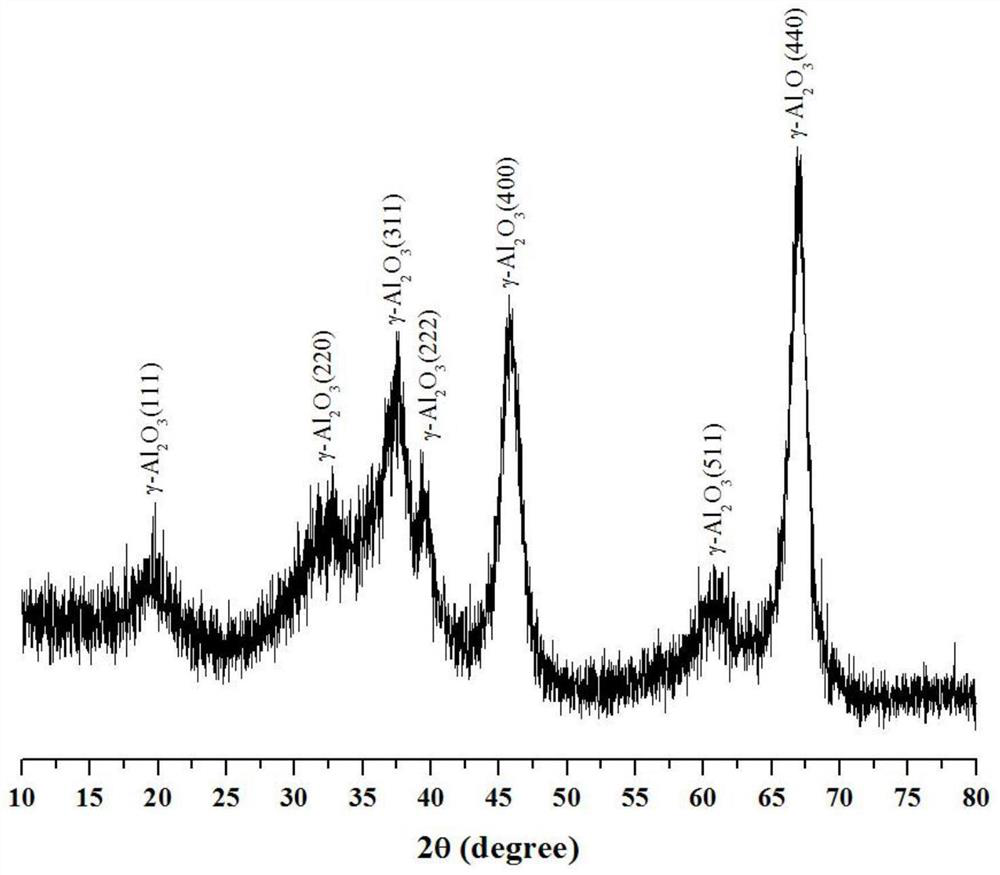

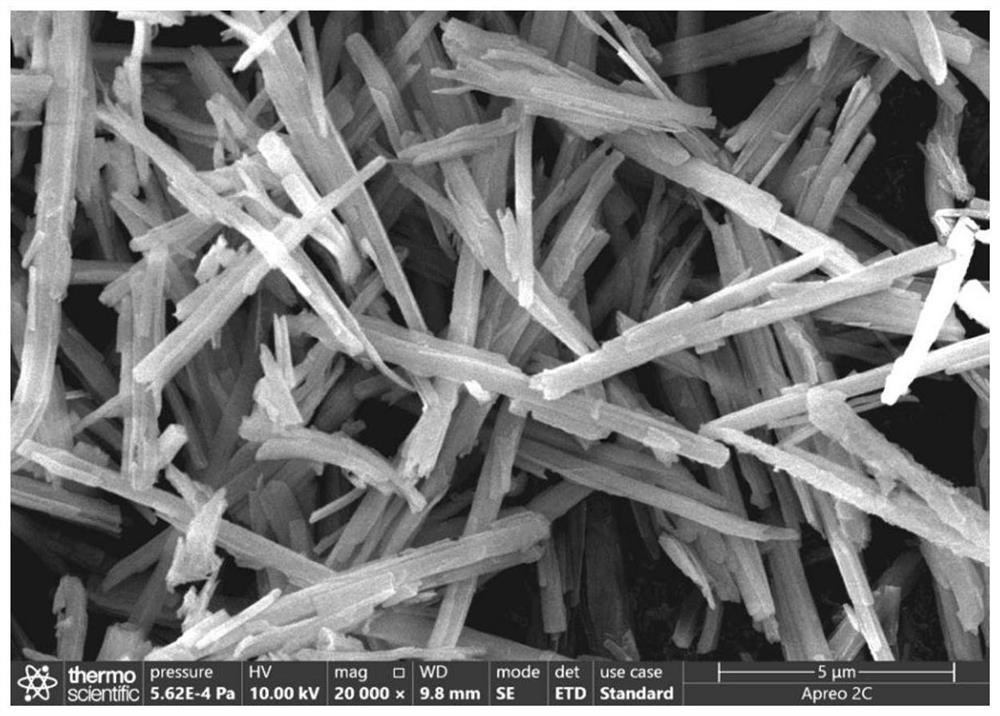

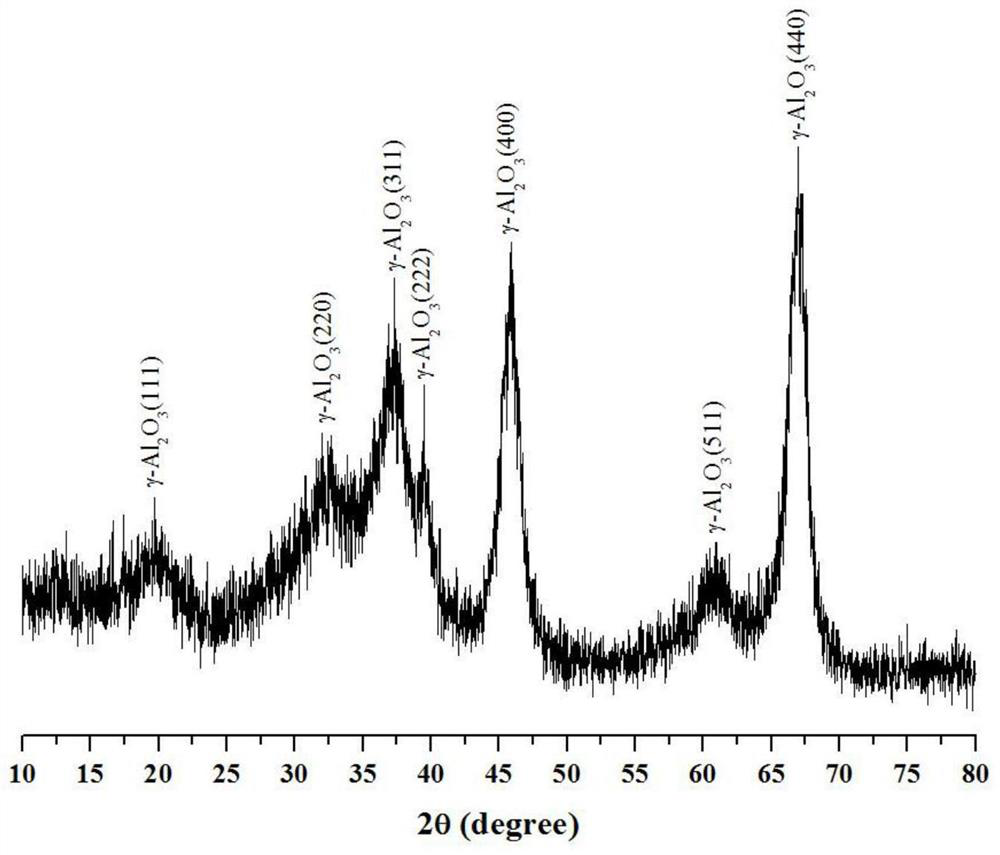

Image

Examples

Embodiment 1

[0035] Gamma alumina fibers sintered in hydrogen

[0036] (1) in deionized water was added Al (NO 3 ) 3 Analytical grade, prepared at a concentration of the aqueous solution of 3mol L / ; Transfer 500 ml of solution, and then 20 g of urea and 20 g of polyethylene glycol, dissolved dispersed by mechanical agitation into the ultrasonic instrument; until the solution became clear and transparent after allowed to stand in air for 12 hours standby; the solution was poured into water after heat aging vessel, one-fifth of retained voids, capped and tightened; hot water kettle was placed in a drying oven to heating rate 2 ℃ / min heating to 280 deg.] C, and then incubated at this temperature for 120 hours, then the power is off, the water in the autoclave and then cooled.

[0037] (2) hot water tank is opened, pouring the reaction solution was not clear and transparent, the white precipitate was poured into a suction funnel vacuum filtration, and washed with deionized water until no odor o...

Embodiment 2

[0042] Gamma alumina fibers sintered in acetylene

[0043] (1) in deionized water was added Al (NO 3 ) 3 AR, formulated at a concentration of 10mol L aqueous / ; Transfer 500 ml of solution, and then 50 g of urea and 100 grams of polyethylene glycol, by mechanically stirring the dispersed and dissolved into a sonicator; until the solution became clear and transparent after allowed to stand in air for 12 hours standby; the solution was poured into water after heat aging vessel, one-fifth of retained voids, capped and tightened; hot water kettle was placed in a drying oven to heating rate 2 ℃ / min heating to 200 ℃, then incubated for 48 hours at this temperature, then turn off the power, the water in the autoclave and then cooled.

[0044](2) Open the heating kettle, pour out the clear and transparent unreacted solution, pour the white precipitate into the suction funnel for vacuum filtration, and use deionized water to clean until there is no obvious ammonia odor; Filtered fiber pr...

Embodiment 3

[0049] Sintered Gamma alumina fibers in methane

[0050] (1) Add Al (NO) in deionized water 3 ) 3 The analysis was purified, the concentration of 5 mol / L was prepared; 500 ml of solution was added, then 40 g of urea and 10 grams of polyethylene glycol were added, and the dispersion dissolved in the ultrasound meter after mechanical stirring; after the solution became clear and transparent Stand for 12 hours in the air; pour the aged solution into the water heater, retain one-fifth of the gap, cover the cover and tighten; put the hydrotherm into the blast drying tank, The temperature rise rate of 2 ° C / min was heated to 250 ° C, and then the temperature was held for 240 hours, then the power is turned off, and the hydrothelin is cooled with the furnace.

[0051] (2) Open the heating kettle, pour out the clear and transparent unreacted solution, pour the white precipitate into the suction funnel for vacuum filtration, and use deionized water to clean until there is no obvious am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com