Method for preparing silver-doped nano nickel hydroxide anode material

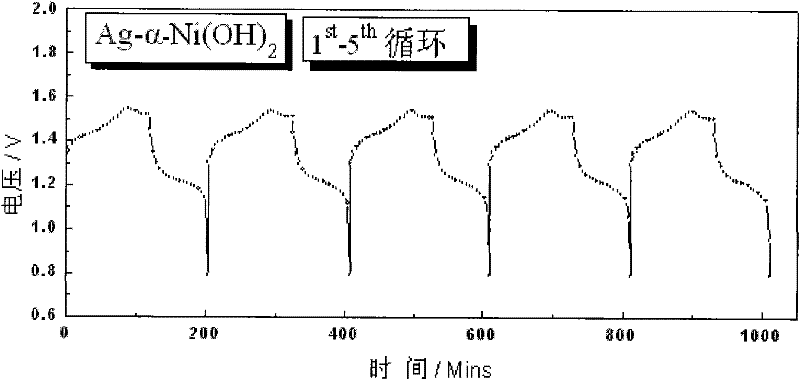

A technology of nickel hydroxide and positive electrode material, applied in battery electrodes, alkaline battery electrodes, electrical components, etc., can solve the problems of battery inflation, reduce electrode discharge specific capacity, low electrode discharge capacity, etc., and achieve high current discharge performance The effect of improving, excellent rate charge and discharge performance, and improved proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

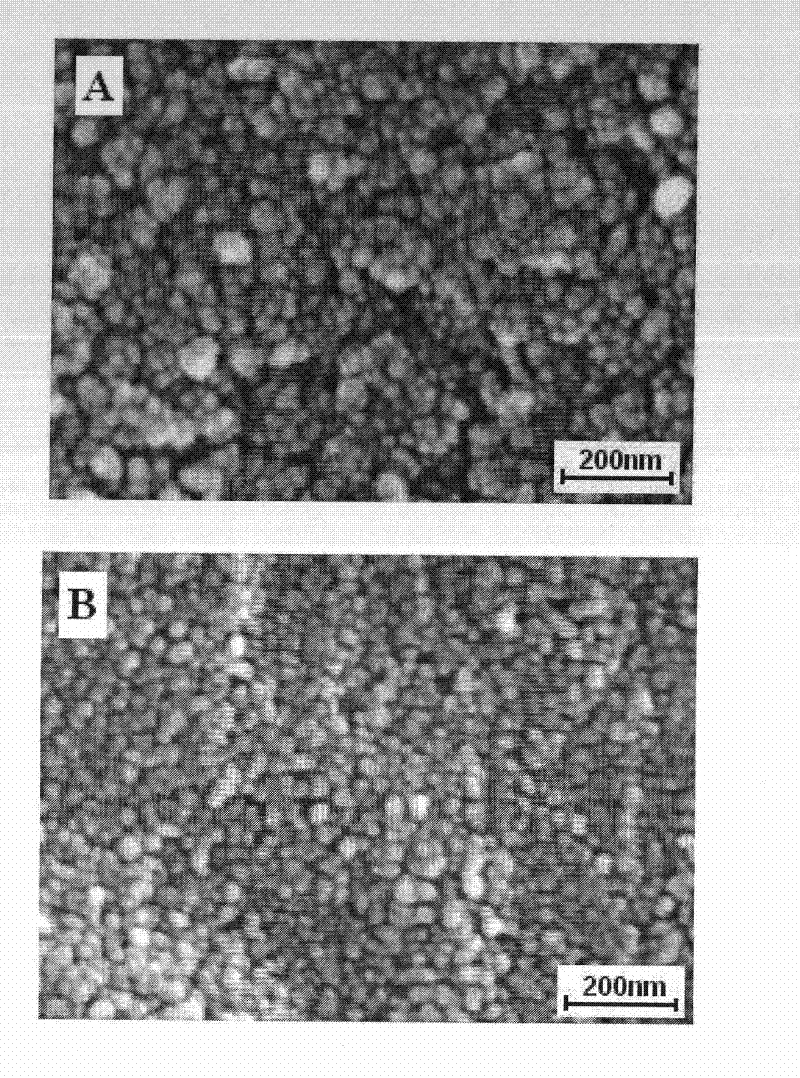

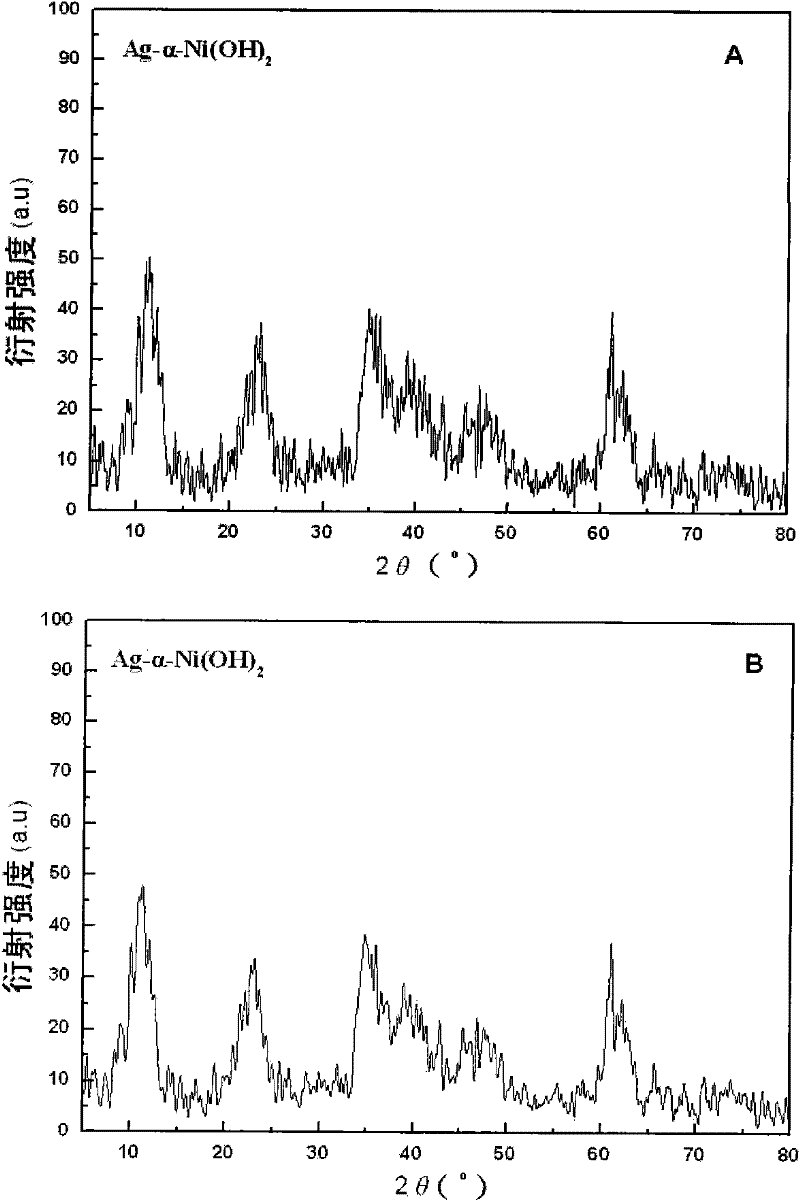

Image

Examples

Embodiment 1

[0034] The first step is to mix nickel nitrate, aluminum nitrate and silver nitrate with a molar ratio of 100:10:0.1, dissolve them in water to form a reaction solution with a nickel ion concentration of 0.1mol / L; prepare a 0.1mol / L KOH solution;

[0035] In the second step, under the conditions of stirring and ultrasonic dispersion, the 0.1mol / L KOH solution containing KOH molar weight prepared in the first step is 2 times the total molar weight of nickel, aluminum and silver ions is added dropwise to the above-mentioned , aluminum and silver ions in the reaction solution, control the addition rate of the KOH solution so that the pH of the reaction system = 8, control the reaction temperature to 25 ° C, stop stirring after 10 minutes of dripping, and continue ultrasonic dispersion for 5 minutes to obtain light gray-green silver Doped nano α-nickel hydroxide precipitation;

[0036] In the third step, the silver-doped nanometer α-nickel hydroxide precipitate obtained in the sec...

Embodiment 2

[0039] In the first step, nickel salt (nickel sulfate and nickel acetate mixed in equimolar ratio), aluminum salt (aluminum sulfate and aluminum acetate mixed in equimolar ratio) and silver in the molar ratio of nickel, aluminum and silver are 100:15:0.5 Salt (silver acetate), dissolved in water is made into the reaction solution that nickel ion concentration is 0.5mol / L; The NaOH solution of preparation 1mol / L;

[0040] In the second step, under the condition of stirring and ultrasonic dispersion, the 1mol / L NaOH solution containing NaOH molar weight prepared in the first step is 2.1 times of the total molar weight of nickel, aluminum and silver ions is added dropwise to the , aluminum and silver ions in the reaction solution, control the addition rate of NaOH solution so that the pH of the reaction system = 9, control the reaction temperature to 65 ° C, stop stirring after 30 minutes, and continue ultrasonic dispersion for 20 minutes to obtain light gray-green Silver doped n...

Embodiment 3

[0044] In the first step, nickel salt (nickel sulfate, nickel nitrate and nickel acetate mixed in equimolar ratio), aluminum salt (aluminum nitrate and aluminum sulfate mixed in equimolar ratio) with nickel, aluminum and silver molar ratio of 100:20:1.5 and aluminum acetate) and silver salt (silver nitrate and silver acetate mixed in an equimolar ratio), dissolved in water to form a reaction solution with a nickel ion concentration of 5mol / L; prepare a 10mol / L NaOH solution;

[0045] In the second step, under the conditions of stirring and ultrasonic dispersion, the 10mol / L NaOH solution prepared in the first step, containing NaOH molar weight 2.5 times the total molar weight of nickel, aluminum and silver ions, is added dropwise to the above-mentioned In the reaction solution containing nickel, aluminum and silver ions, control the addition rate of NaOH solution so that the pH of the reaction system is 13, and control the reaction temperature at 55°C. After 120 minutes of drip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com