Copper colloid catalyst solution for electroless copper plating and electroless copper plating method

An electroless copper plating and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as coating defects, coating streaks, coatings, etc., to increase productivity, improve effects, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

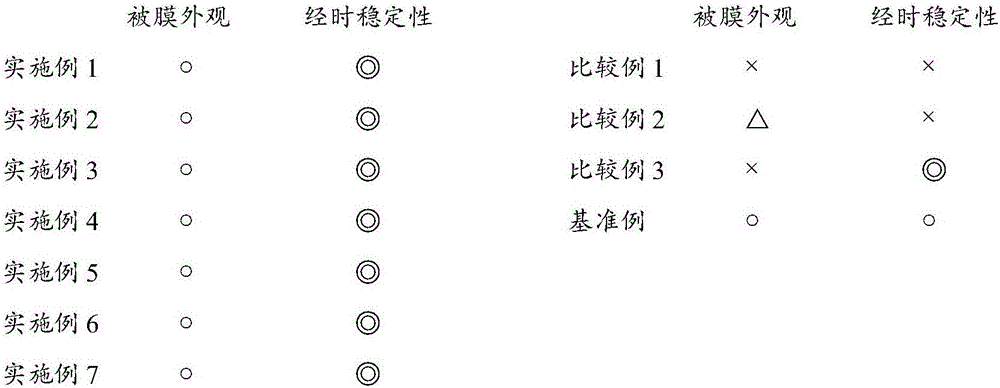

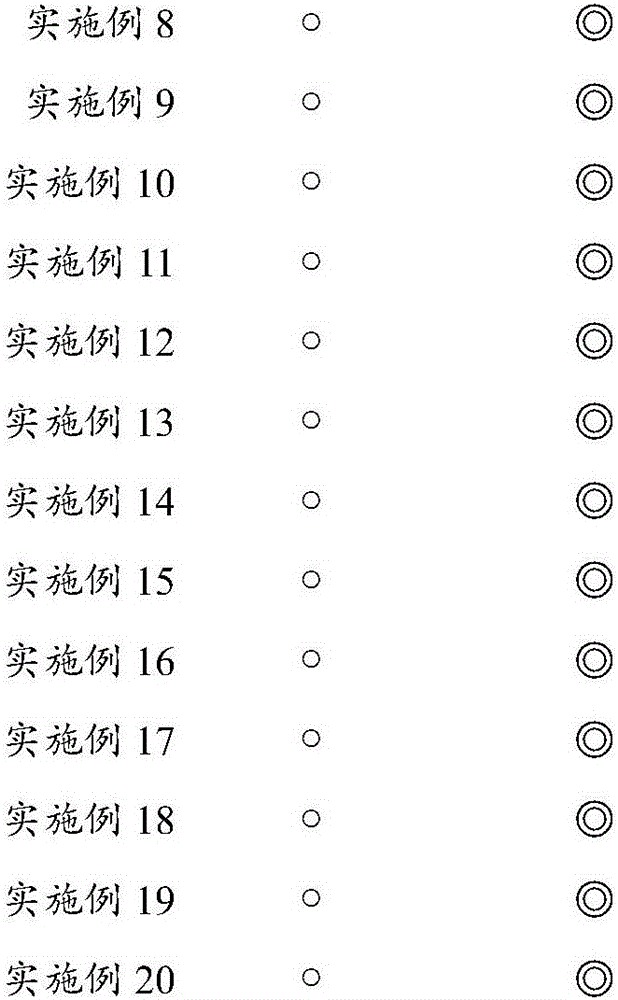

[0147] Embodiment 1 is to use citric acid as colloid stabilizer in catalyst liquid, use xylitol (sugar alcohol) as carbohydrate, use sodium borohydride and hypophosphorous acid as the example of reducing agent. Example 2 is an example in which the content of xylitol is adjusted to the lower limit of the above-mentioned normal range based on Example 1, and Example 3 is an example in which the content of xylitol is adjusted to the upper limit of the above-mentioned normal range. Embodiment 4 is the example that carbohydrate uses sorbitol (sugar alcohol), similarly embodiment 5 is the example that carbohydrate uses mannitol (sugar alcohol), and embodiment 6 is the example that carbohydrate uses gluconolactone (monosaccharide) derivatives), Example 7 is an example of carbohydrates using glucose (monosaccharides), and Example 8 is an example of carbohydrates using maltose (disaccharides). Embodiment 9 is an example in which carbohydrates use xylitol, and synthetic water-soluble pol...

Embodiment 2

[0184] Based on the above-mentioned Example 1, the copper colloidal catalyst solution is prepared according to the following composition. In addition, the liquid containing the adsorption accelerator, the composition of the electroless copper plating solution, and the processes of adsorption promotion, catalyst imparting, and electroless copper plating The conditions are the same as in Example 1.

[0185] (b) Preparation of Copper Colloidal Catalyst Liquid

[0186] [copper solution]

[0187] Copper sulfate (as Cu 2+ Count): 0.1 mol / L

[0188] Citric acid: 0.2 mol / L

[0189] Xylitol: 0.001 mol / L

[0190] [reducing agent solution]

[0191] Sodium borohydride: 0.02 mol / L

[0192] Hypophosphorous acid: 0.18 mol / L

[0193] The reducing agent solution was added dropwise to the 25° C. copper solution adjusted to pH 4.0 and stirred for 45 minutes to prepare a copper colloidal catalyst solution.

[0194] The molar ratios of the respective components of the catalyst liquid are as ...

Embodiment 3

[0198] Based on the above-mentioned Example 1, the copper colloidal catalyst solution is prepared according to the following composition. In addition, the liquid containing the adsorption accelerator, the composition of the electroless copper plating solution, and the processes of adsorption promotion, catalyst imparting, and electroless copper plating The conditions are the same as in Example 1.

[0199] (b) Preparation of Copper Colloidal Catalyst Liquid

[0200] [copper solution]

[0201] Copper sulfate (as Cu 2+ Count): 0.1 mol / L

[0202] Citric acid: 0.2 mol / L

[0203] Xylitol: 4.0 mol / L

[0204] [reducing agent solution]

[0205] Sodium borohydride: 0.02 mol / L

[0206] Hypophosphorous acid: 0.18 mol / L

[0207] The reducing agent solution was added dropwise to the 25° C. copper solution adjusted to pH 4.0 and stirred for 45 minutes to prepare a copper colloidal catalyst solution.

[0208] The molar ratios of the respective components of the catalyst liquid are as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com