Production method and equipment of low-sodium-content blanching-free steamed hot dry noodles

A production method and a technology for hot-dried noodles, which are applied in the field of low-sodium non-blanching steamed hot-dried noodles, can solve the problems of low work efficiency, loss of flour nutrition, high labor intensity, etc., and achieve energy saving, water saving, and nutrition prevention. drain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

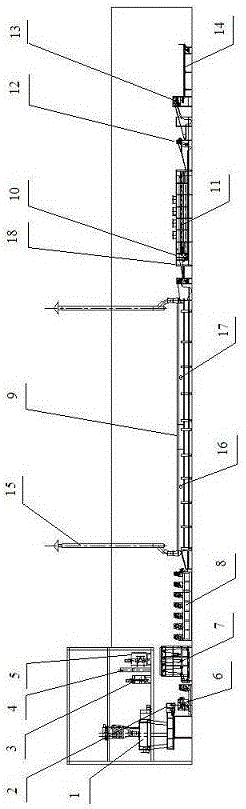

[0021] The production method of low-sodium non-blanching steamed hot dry noodles is to mix the selected flour with water and sodium salt in proportion, then ripen, press into pieces, cut into strips, steam, air-cooled, mixed with oil, pine, It is made by cutting and bagging. The specific process flow procedure is as follows:

[0022] (1) Material selection: the main raw material is Handan Guang brand flour in Hebei;

[0023] (2) Kneading dough: Add flour into the powder storage hopper through a vibrating sieve, add 30-38% water and 0.1-0.2 sodium salt according to the weight ratio of flour, and fully stir for 10-15 minutes through the dough mixer;

[0024] (3) Aging: Send the reconciled dough to the noodle belt aging machine for 15-20 minutes through the noodle conveyor and single-chip microcomputer;

[0025] (4) Pressing and cutting: the matured noodle strips are pressed into thin sheets through seven rolls of the continuous calender, and cut into noodles by blades;

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com