Polydopamine-coated nanometer composite photothermal reagent and preparation method thereof

A polydopamine and nanocomposite technology, which is applied in the photodissociation of drugs in the body, medical preparations containing active ingredients, drug combinations, etc., can solve the loss of morphology and optical properties, photothermal stability needs to be improved, and biological Compatibility reduction and other problems, to achieve the effects of improved physiological environment stability and photothermal stability, improved photothermal conversion efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

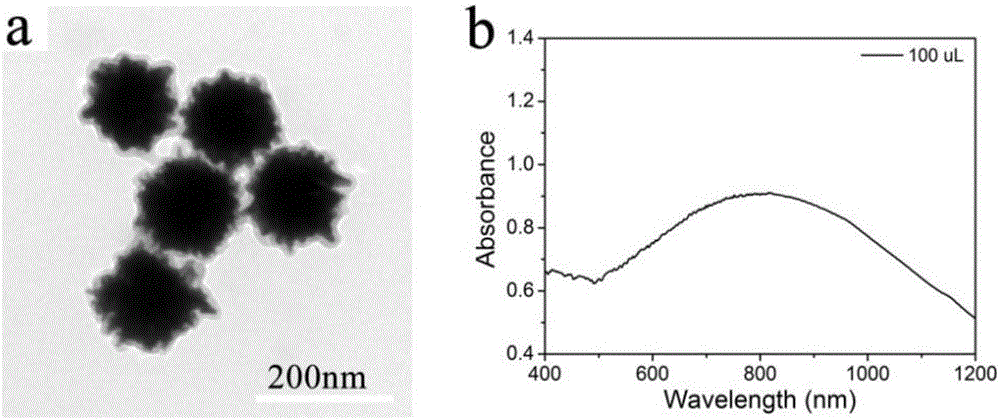

[0034] Use the first method to coat polydopamine shells on inorganic nanoparticles: first dissolve 1 mg of gold and silver dendritic nanoparticles to be coated in 5 mL of water, add 5 mL of 0.02 M Tris buffer solution and assist hydrochloric acid solution to adjust the pH of the reaction system to 8.5, then add 100 μL, 0.03M dopamine solution (nanoparticle: dopamine monomer concentration = 0.1 mg / mL: 0.045 mg / mL), stir at room temperature for 3 hours, then centrifuge the above solution to obtain polydopamine-coated Nanocomposite photothermal reagent; the thickness of the polydopamine shell is 6nm, and the surface plasmon resonance peak after coating the polydopamine shell is 811nm (the dopamine coated on the surface of the nanoparticles only accounts for a small part of the input dopamine, and the mass is very small, relatively negligible compared to inorganic nanoparticles).

[0035] The size of the gold and silver dendritic nanoparticles is about 135nm, and the plasmon reson...

Embodiment 2

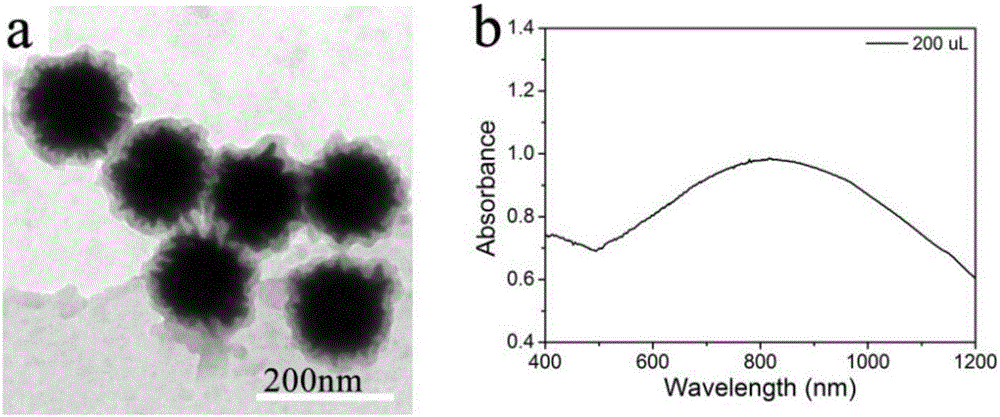

[0037] The first method is used to coat the polydopamine shell layer on the inorganic nanoparticles: first, 1 mg of gold and silver dendritic nanoparticles described in Example 1 to be coated are dissolved in 5 mL of water, and 5 mL of 0.02 M Tris buffer solution is added and assisted Hydrochloric acid solution adjusts the pH of the reaction system to 8.5 (the buffer solution only provides an alkaline environment and does not participate in the reaction), and then adds 200 μL, 0.03M dopamine solution (nanoparticle: dopamine monomer concentration = 0.1 mg / mL: 0.090 mg / mL ), stirred at room temperature for 3 hours, then centrifuged the above solution to separate and obtain the nanocomposite photothermal reagent coated with polydopamine; the thickness of the polydopamine shell was 10nm, and the surface plasmon resonance peak after coating the polydopamine shell was 817nm.

Embodiment 3

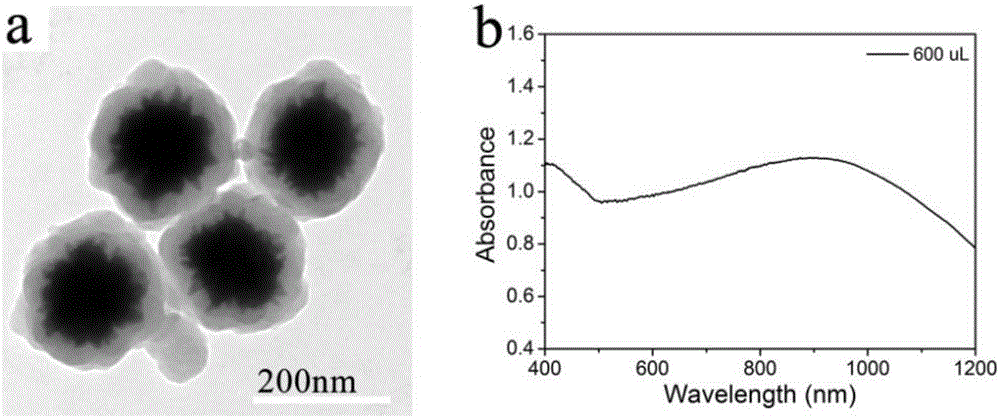

[0039] The first method is used to coat the polydopamine shell layer on the inorganic nanoparticles: first, 1 mg of gold and silver dendritic nanoparticles described in Example 1 to be coated are dissolved in 5 mL of water, and 5 mL of 0.02 M Tris buffer solution is added and assisted Hydrochloric acid solution adjusts the pH of the reaction system to 8.5 (the buffer solution only provides an alkaline environment and does not participate in the reaction), and then adds 600 μL, 0.03M dopamine solution (nanoparticle: dopamine monomer concentration=0.1mg / mL: 0.260mg / mL ), stirred at room temperature for 3 hours, then centrifuged the above solution to separate and obtain a nanocomposite photothermal reagent coated with polydopamine; the thickness of the polydopamine shell was 34nm, and the surface plasmon resonance peak after coating the polydopamine shell was 917nm.

[0040] Examples 1 to 3 illustrate that the first method is used to coat polydopamine shells on the surface of gold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com