Chitosan-modified sodium bentonite, preparation method and application

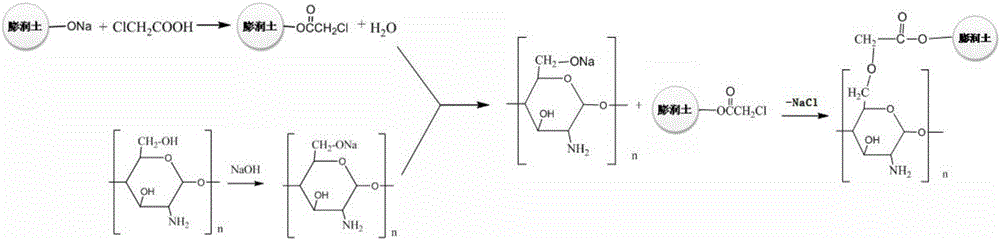

A sodium-based bentonite and chitosan modification technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of increasing the distance between the original soil layers, and increase the adsorption surface area. , the reaction conditions are mild, and the preparation process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Chitosan modified sodium bentonite is prepared by the following steps:

[0042] 1) Preparation of intermediate products

[0043] Disperse 0.5g of sodium bentonite in 70mL of isopropanol, stir and mix for 30min, add 5g of chloroacetic acid and 3 drops of concentrated sulfuric acid, reflux at 80°C for 5h, filter with suction, collect the solid, and dry at 60°C for 4h for later use ;

[0044] 2) Preparation of modified sodium bentonite

[0045] Disperse 0.5g of chitosan in 70mL of isopropanol, add 1mL of KOH aqueous solution with a concentration of 200g / L, stir and mix, and raise the temperature to 40°C in a water bath, and alkalinize for 70min; then add 0.5g of the product in step 1), and stir Mix and react at a constant temperature at 40°C for 6h. After the reaction is complete, the product is washed with isopropanol, filtered three times, and dried at 60°C for 4h to obtain the product.

Embodiment 2

[0047]Chitosan modified sodium bentonite is prepared by the following steps:

[0048] 1) Preparation of intermediate products

[0049] Disperse 0.5g of sodium bentonite in 100mL of isopropanol, stir and mix for 30min, add 4.5g of chloroacetic acid and 4 drops of concentrated sulfuric acid, reflux at 70°C for 6h, filter with suction, collect the solid, and dry at 50°C for 5h spare;

[0050] 2) Preparation of modified sodium bentonite

[0051] Disperse 0.5g of chitosan in 70mL of isopropanol, add 1mL of KOH aqueous solution with a concentration of 180g / L, stir and mix, and raise the temperature to 45°C in a water bath, and alkalinize for 1h; then add 0.4g of the product in step 1), and stir Mix and react at a constant temperature at 30°C for 7h. After the reaction is complete, the product is washed with isopropanol, filtered three times, and dried at 50°C for 5h to obtain the product.

Embodiment 3

[0053] Chitosan modified sodium bentonite is prepared by the following steps:

[0054] 1) Preparation of intermediate products

[0055] Disperse 0.5g of sodium bentonite in 120mL of isopropanol, stir and mix for 30min, add 5.5g of chloroacetic acid and 4 drops of concentrated sulfuric acid, reflux at 90°C for 4h, filter with suction, collect the solid, and dry at 70°C for 3h spare;

[0056] 2) Preparation of modified sodium bentonite

[0057] Disperse 0.5g of chitosan in 70mL of isopropanol, add 1mL of KOH aqueous solution with a concentration of 220g / L, stir and mix, and raise the temperature to 50°C in a water bath, and alkalinize for 50min; then add 0.6g of the product in step 1), and stir Mix and react at a constant temperature at 50°C for 5h. After the reaction is complete, the product is washed with isopropanol, filtered three times, and dried at 70°C for 3h to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com