Preparation method of modified oil shale semicoke adsorbent

An oil shale semi-coke and adsorbent technology, which is applied in the field of preparation of modified oil shale semi-coke adsorbent, can solve the problems of high price of activated carbon, increased environmental protection cost and the like, and achieves fast heating speed, energy saving and energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

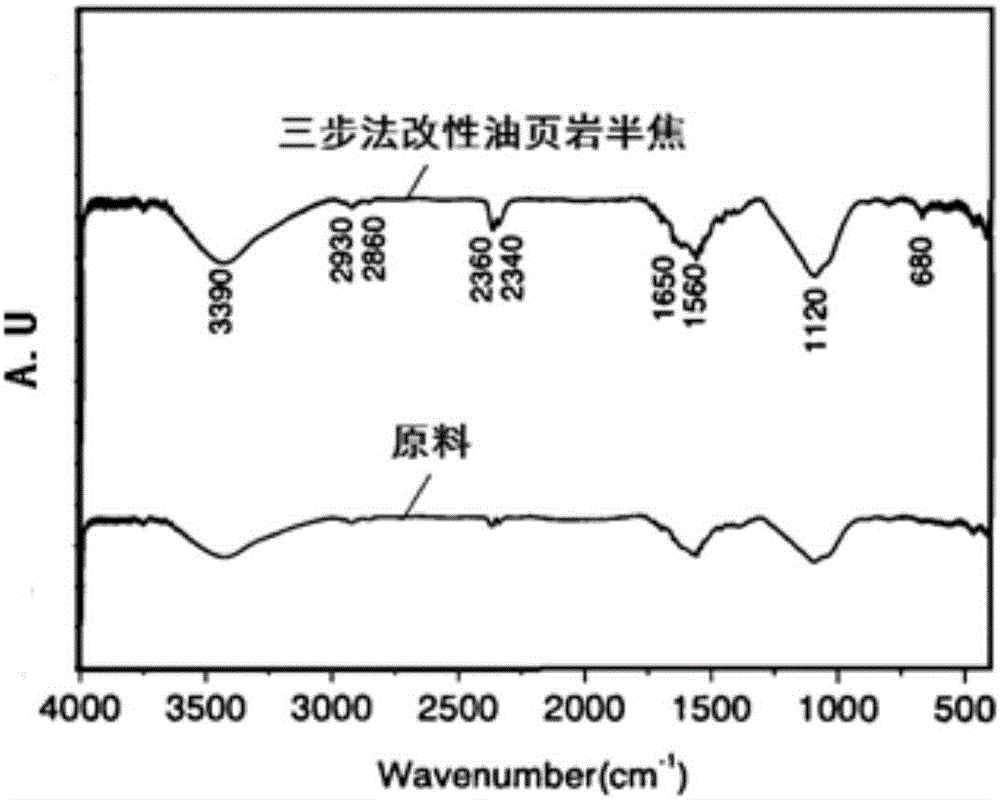

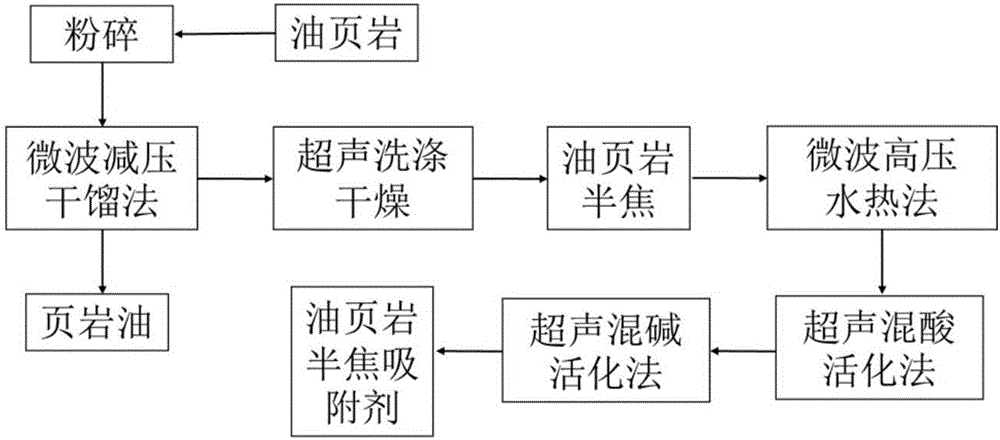

[0053] In this example, a modified oil shale semi-coke adsorbent is prepared by combining modified oil shale semi-coke through a three-step method, such as image 3 As shown, the specific steps are as follows:

[0054] 1. Dry distillation

[0055] The oil shale is dry-distilled by the microwave vacuum dry distillation method, and the specific steps are as follows:

[0056] First, crush the oil shale sample with a crusher, weigh 200g of oil shale particles with a diameter of 6-8mm and place them in the retort bottle of the vacuum retort device, connect the condensing device, vacuum pump, collection bottle and other devices, and turn on the vacuum pump The pressure was adjusted to -0.05MPa, and microwave equipment was used to heat it at the same time, and the oil shale was subjected to microwave vacuum dry distillation at 1000MHz and 300°C for 4 hours to obtain shale oil and oil shale semi-coke particles.

[0057] 2. Ultrasonic washing and drying

[0058] The oil shale semi-c...

Embodiment 2

[0074] In this example, a modified oil shale semi-coke adsorbent was prepared by combining modified oil shale semi-coke through a two-step method. The specific steps are as follows:

[0075] 1. Dry distillation

[0076] The oil shale is dry-distilled by the microwave vacuum dry distillation method, and the specific steps are as follows:

[0077] First, crush the oil shale sample with a crusher, weigh 200g of oil shale particles with a diameter of 8-10mm and place them in the retort bottle of the vacuum retort device, connect the condensing device, vacuum pump, collection bottle and other devices, and turn on the vacuum pump The pressure was adjusted to -0.1MPa, and microwave equipment was used to heat it at the same time. Under the conditions of 500MHz and 600°C, the oil shale was subjected to microwave vacuum dry distillation for 5 hours to obtain shale oil and oil shale semi-coke particles.

[0078] 2. Ultrasonic washing and drying

[0079] Put the above-mentioned semi-cok...

Embodiment 3

[0088]In this example, a modified oil shale semi-coke adsorbent was prepared by combining modified oil shale semi-coke through a two-step method. The specific steps are as follows:

[0089] 1. Dry distillation

[0090] The oil shale is dry-distilled by the microwave vacuum dry distillation method, and the specific steps are as follows:

[0091] First, crush the oil shale sample with a crusher, weigh 200g of oil shale particles with a diameter of 6-8mm and place them in the retort bottle of the vacuum retort device, connect the condensing device, vacuum pump, collection bottle and other devices, and turn on the vacuum pump The pressure was adjusted to -0.02MPa, and microwave equipment was used to heat it at the same time, and the oil shale was subjected to microwave vacuum dry distillation at 3000MHz and 400°C for 3 hours to obtain shale oil and oil shale semi-coke particles.

[0092] 2. Ultrasonic washing and drying

[0093] Put the above-mentioned semi-coke particles and di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com