Method for preparing hydroxyapatite nano rod by adopting hydrothermal method

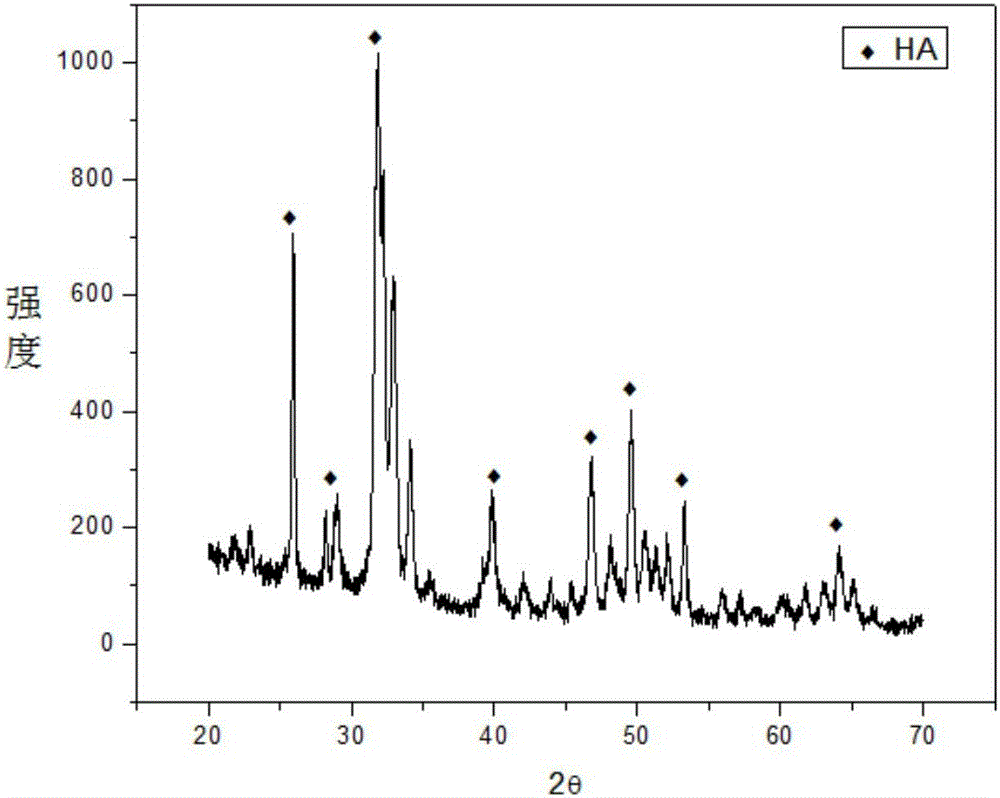

A technology of hydroxyapatite and nanorods, applied in nanotechnology, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of reducing the repeatability of the preparation process and increasing the complexity of the process, and achieve single shape and high purity , good process repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Under the condition of high-speed stirring, the phosphoric acid solution was added dropwise into the calcium hydroxide suspension, and reacted for 6 hours. After the reaction, the product was centrifuged, ball milled, and aged.

[0025] The molar ratio of described calcium hydroxide and phosphoric acid is 5:3.

[0026] (2) Centrifuge the aging solution obtained in (1), place the obtained precipitate in a polytetrafluoroethylene-lined hydrothermal kettle, control the volume ratio to 50%, and place the hydrothermal kettle in a 150°C oven for hydrothermal reaction for 5 Hour.

[0027] (3) Cool the hydrothermal kettle after the reaction in (2) to room temperature, wash the precipitate in the kettle with absolute ethanol, and dry at 80°C.

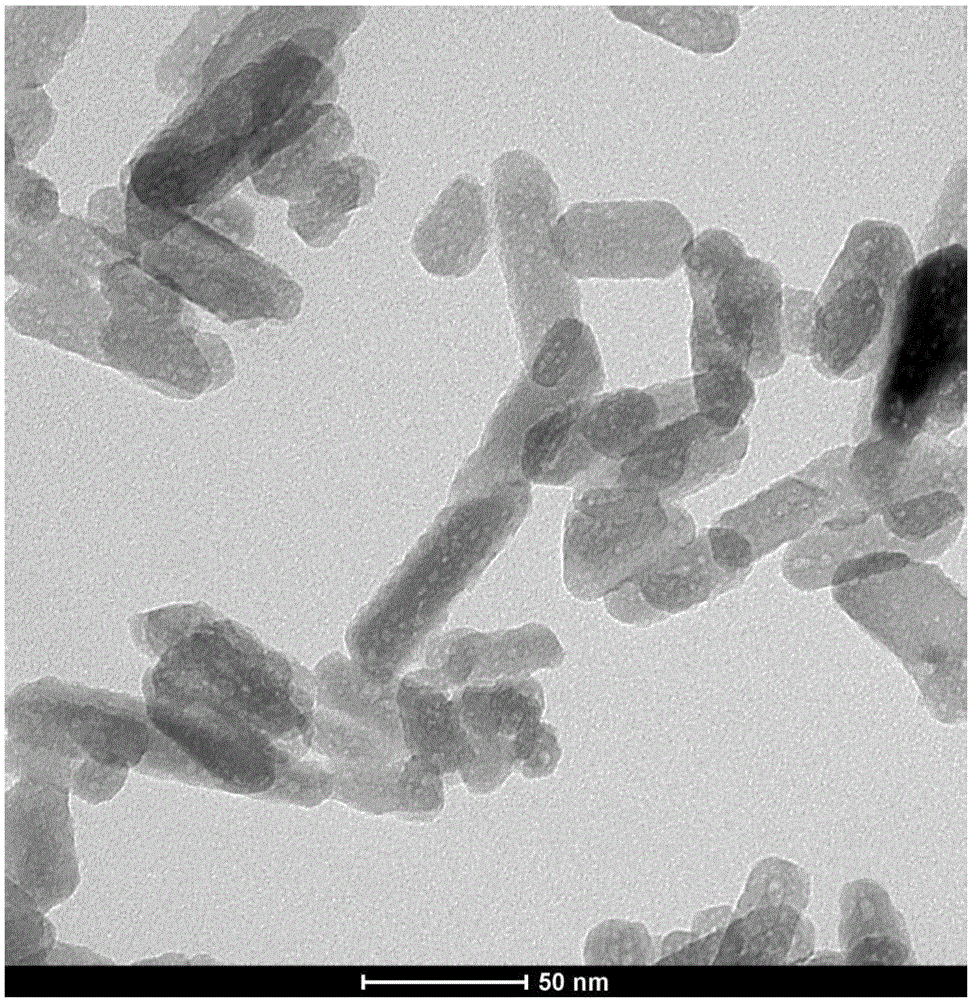

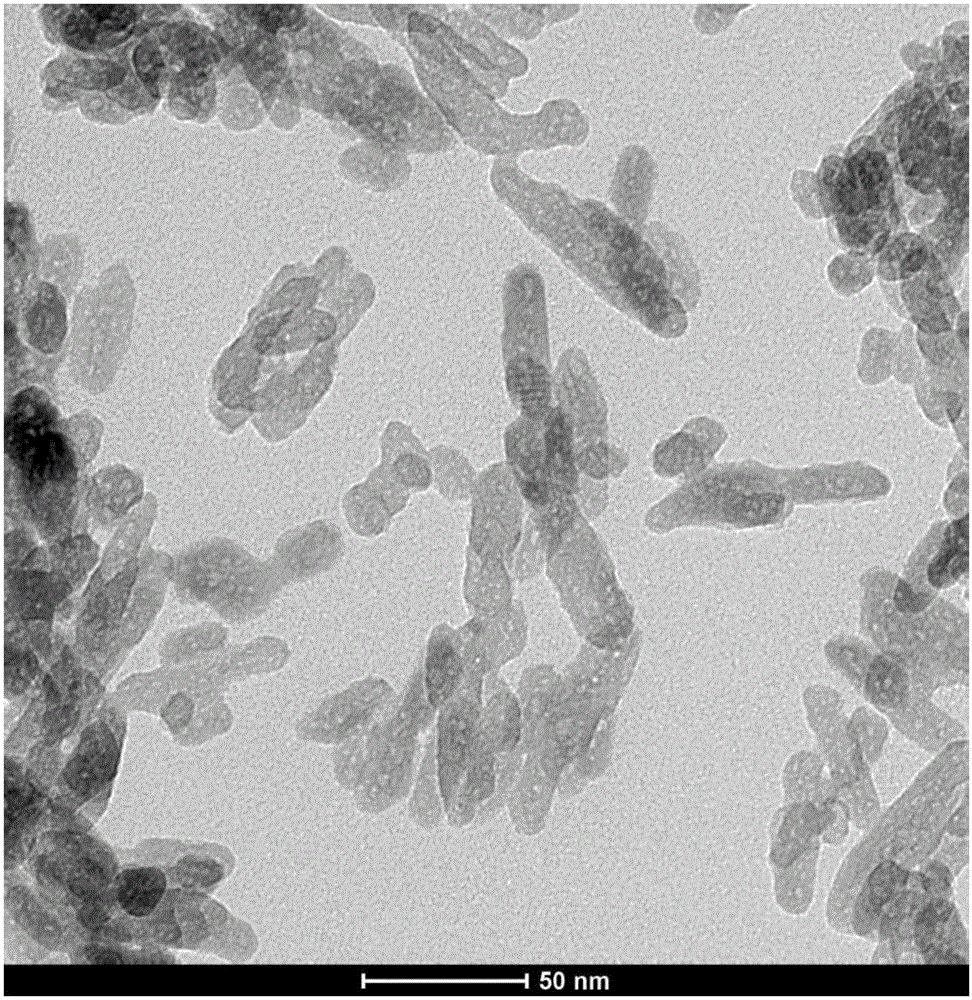

[0028] Observation by transmission electron microscope shows that the obtained hydroxyapatite nanorods have a length of 50-80nm and a diameter of 15-30nm.

Embodiment 2

[0030] (1) Under the condition of high-speed stirring, the phosphoric acid solution was added dropwise into the calcium hydroxide suspension, and reacted for 6 hours. After the reaction, the product was centrifuged, ball milled, and aged.

[0031] The molar ratio of described calcium hydroxide and phosphoric acid is 5:3.

[0032] (2) Centrifuge the aging solution obtained in (1), place the obtained precipitate in a polytetrafluoroethylene-lined hydrothermal kettle, control the volume ratio to 60%, and place the hydrothermal kettle in a 120°C oven for hydrothermal reaction for 5 Hour.

[0033] (3) Cool the hydrothermal kettle after the reaction in (2) to room temperature, wash the precipitate in the kettle with absolute ethanol, and dry at 80°C.

[0034] Observation by transmission electron microscope shows that the obtained hydroxyapatite nanorods have a length of 50-80nm and a diameter of 15-30nm.

Embodiment 3

[0036] (1) Under the condition of high-speed stirring, the phosphoric acid solution was added dropwise into the calcium hydroxide suspension, and reacted for 6 hours. After the reaction, the product was centrifuged, ball milled, and aged.

[0037] The molar ratio of described calcium hydroxide and phosphoric acid is 5:3.

[0038] (2) Centrifuge the aging solution obtained in (1), place the obtained precipitate in a polytetrafluoroethylene-lined hydrothermal kettle, control the volume ratio to 60%, and place the hydrothermal kettle in a 180°C oven for hydrothermal reaction for 5 Hour.

[0039] (3) Cool the hydrothermal kettle after the reaction in (2) to room temperature, wash the precipitate in the kettle with absolute ethanol, and dry at 80°C.

[0040] Observation by transmission electron microscope shows that the obtained hydroxyapatite nanorods have a length of 50-80nm and a diameter of 15-30nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com